Patents

Literature

75results about How to "Friendly operating environment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for extracting rare earth and aluminum from ion adsorption type rare earth ores

ActiveCN105803226AEfficient separationAchieve purificationProcess efficiency improvementAluminum canRare earth

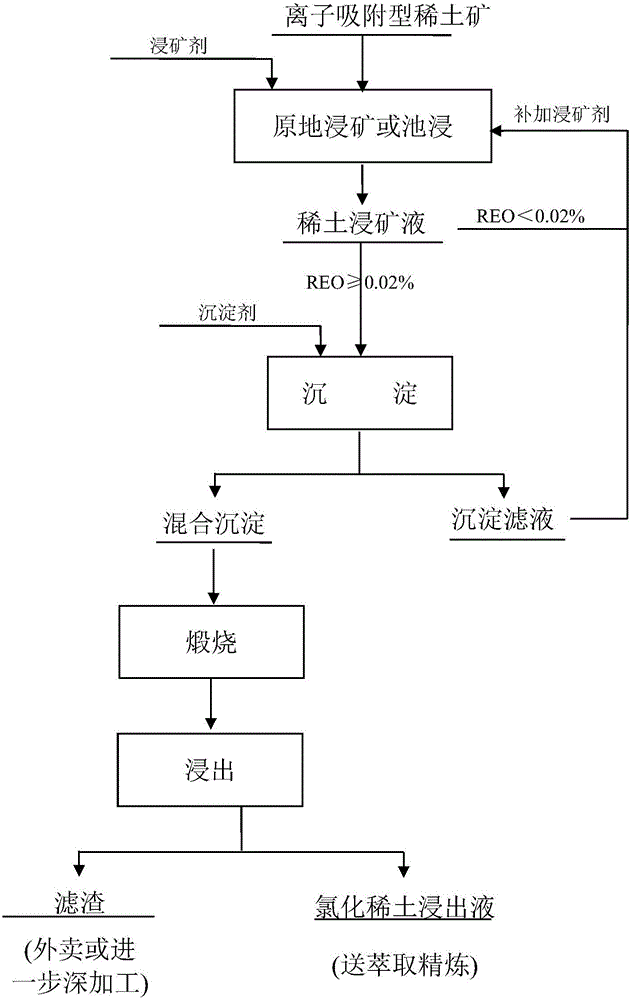

The invention relates to a method for extracting rare earth and aluminum from ion adsorption type rare earth ores. The method includes the steps that (1), ore leaching is performed, wherein an ore leaching agent is added for in-situ ore leaching or pond leaching, and rare earth ore leaching liquid with the rare earth concentration higher than 0.02% is obtained; (2), precipitation is performed, wherein solid and liquid separation is performed after a precipitation agent is added into the rare earth ore leaching liquid for precipitation, and precipitated filter liquor and mixed precipitate containing rare earth and aluminum are obtained; (3), calcination is performed, wherein the mixed precipitate containing rare earth and aluminum is calcinated, and calcinated products containing rare earth oxide and alpha-aluminum oxide are obtained; and (4), leaching out is performed, wherein solid and liquid separation is performed after a chlorination leaching agent is added into the calcinated products containing rare earth oxide and alpha-aluminum oxide for leaching out, chlorinated rare earth leaching-out liquid and filter residues containing alpha-aluminum oxide are obtained, rare earth oxide is extracted from the chlorinated rare earth leaching-out liquid, and aluminum oxide fine products are extracted from the filter residues containing alpha-aluminum oxide. The method is simple in technology, precipitation is directly performed without impurity removal, and by means of the dissolution property difference of the calcinated products in an acid environment, the rare earth and the aluminum can be separated and recycled.

Owner:CHANGSHA RES INST OF MINING & METALLURGY +1

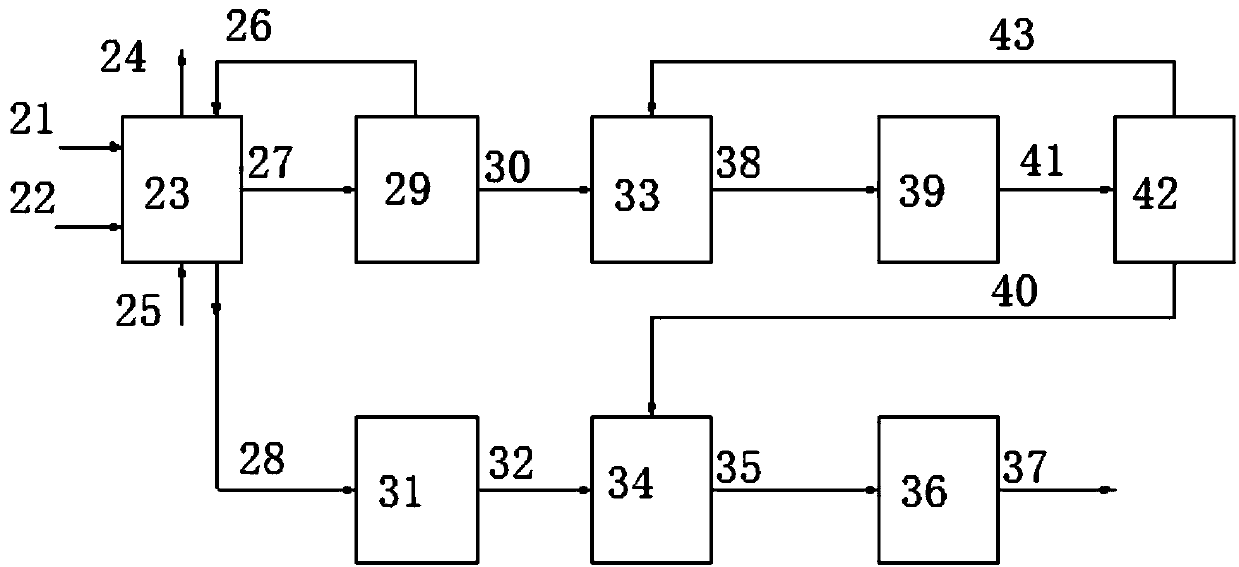

Mobile phone with dynamic switch interface and method of mobile phone interface dynamic switch

InactiveCN101227680AImprove the status of interface static switchingFriendly operating environmentRadio/inductive link selection arrangementsSpecific program execution arrangementsEmbedded systemDisplay memory

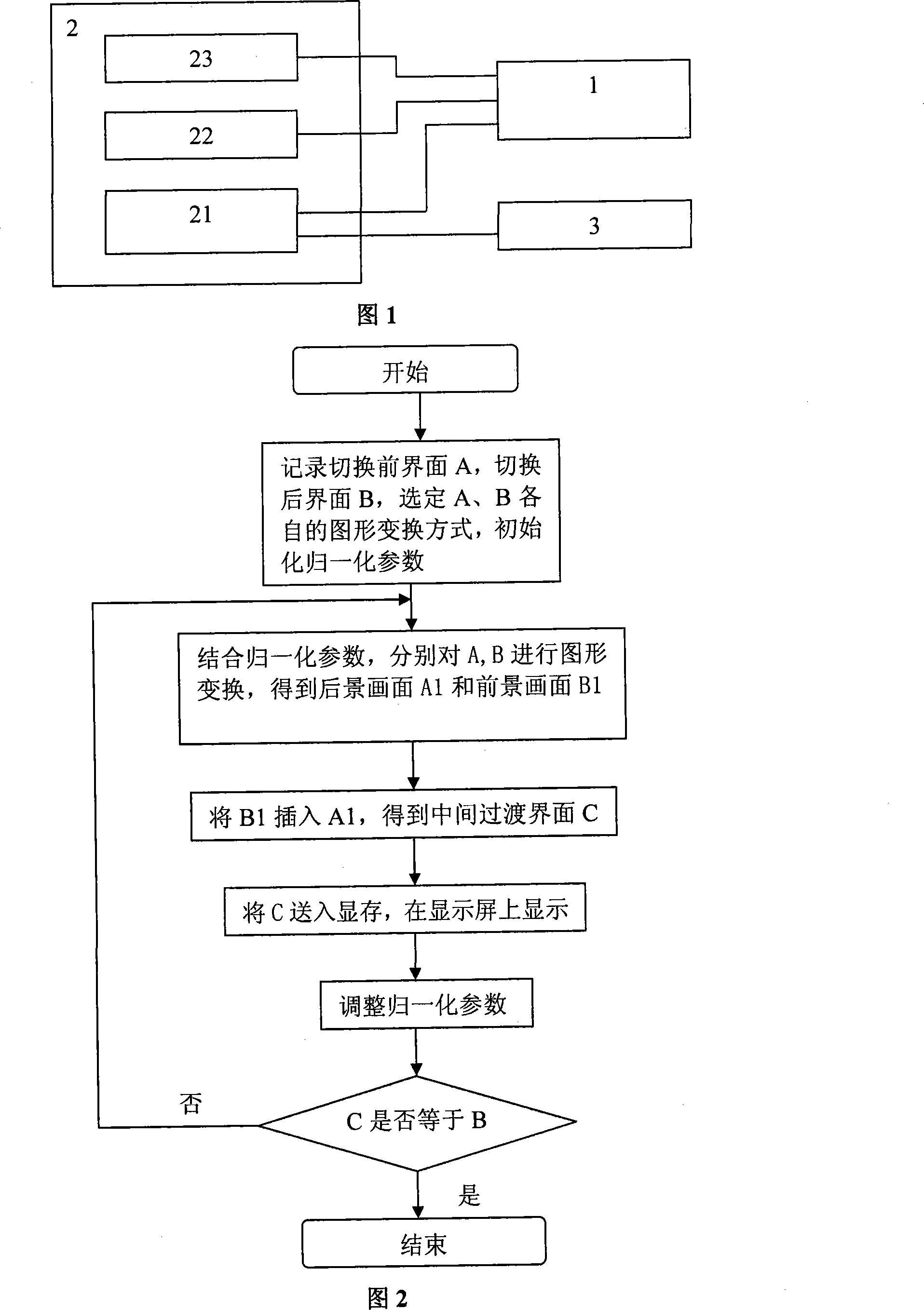

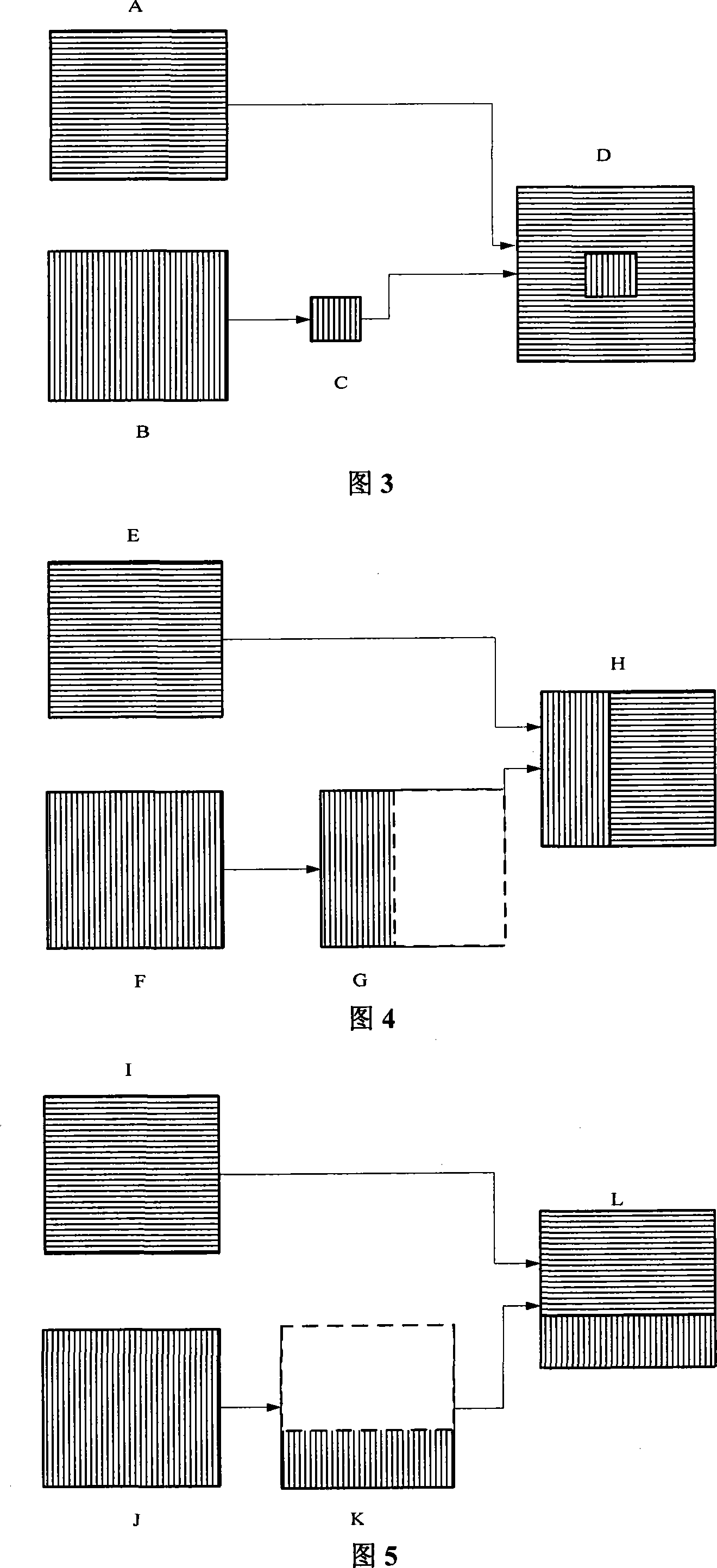

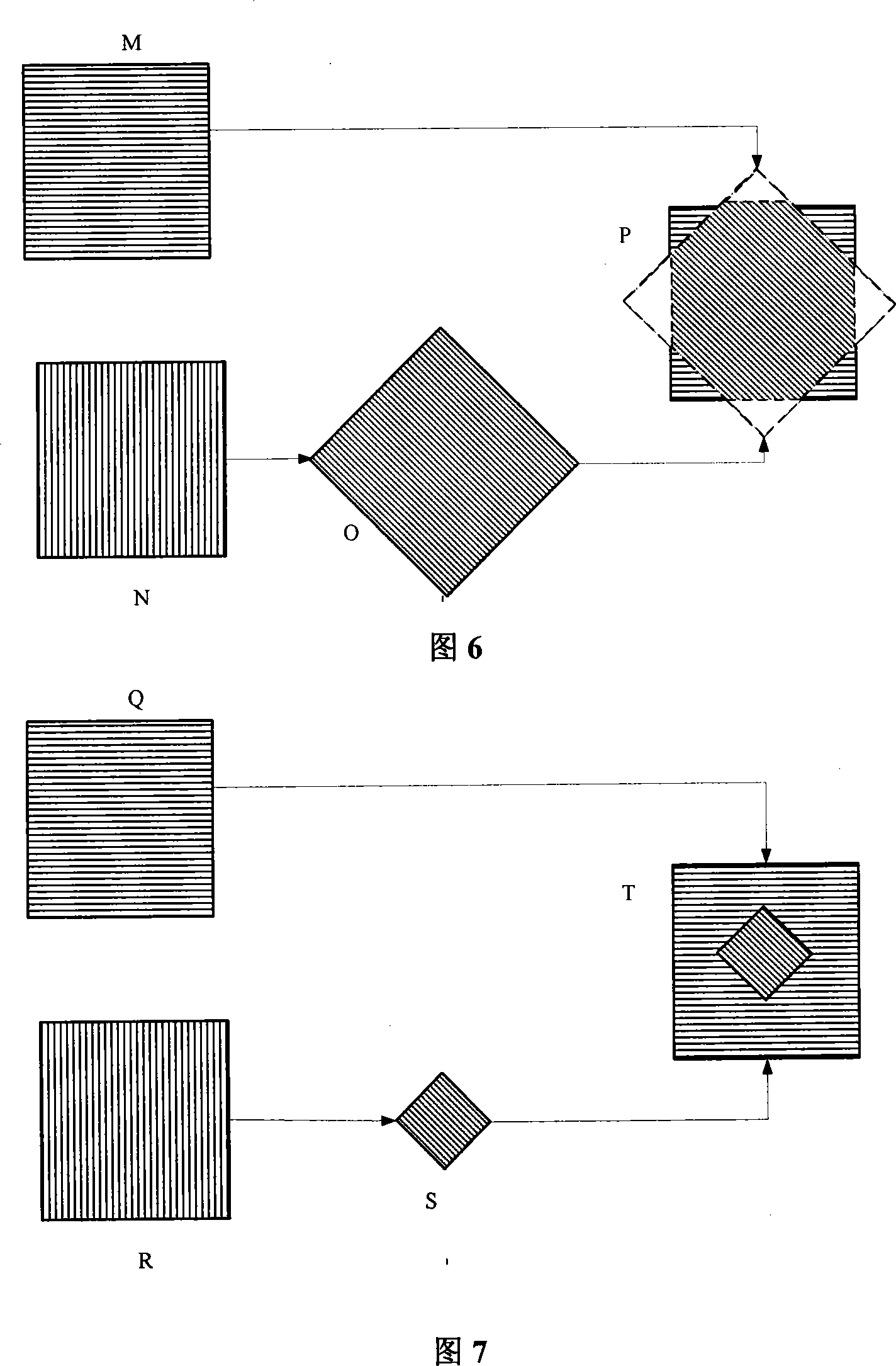

The invention relates to a cell phone and a process, in particular to cell phone with dynamic switching interface and the process of the dynamic switching cell phone interface. The cell phone comprises a CPU, an internal memory which has a display memory and a display screen, and is characterized in that an initial image buffer which stores the interface before switching and a target image buffer which stores the interface after switching are arranged in the internal memory, the CPU is connected with the initial image buffer, the target image buffer and the display memory, and the display memory is connected with the display screen. The dynamic switching of the interface comprises the following steps that conducting the image switching for the interfaces before and after the switching by the CPU combining with the normalized parameter to obtain the background pictures and the foreground pictures, then conducting the insertion connection to gain an intermediate transition interface and inputting to the display screen, continuously conducting of process of the calculation of the CPU and the display of the intermediate interface, and adjusting the asymptotic parameter during the process until the interface after switched is displayed on the display screen. The invention realizes the dynamic switching of the cell phone interface, changes the current condition that the cell phone only has the static switching, and provides more friendly operation environment for users.

Owner:WINGTECH COMM

Method for leaching extracted vanadium from vanadium-containing raw material roasted clinker through ammonium oxalate

The invention provides a method for leaching extracted vanadium from vanadium-containing raw material roasted clinker through ammonium oxalate. The method includes the steps that a mixture of a vanadium-containing raw material and an additive is roasted to obtain a vanadium-containing raw material clinker; the vanadium-containing raw material clinker leaches extracted vanadium in an ammonium oxalate solution, and extracted vanadium tailings and a vanadium-containing leaching solution are obtained after solid-liquid separation. The method is high in vanadium selective leaching rate which can reach 90% or above, the content of vanadium-containing solution impurities obtained after leaching is small, the acidity and the alkalinity are proper, the purification and impurity removal process can be simplified or omitted, and subsequent vanadium precipitation and preparation of high-purity vanadium products are facilitated. No salt-containing waste water is generated. A leaching agent, namely the ammonium oxalate solution, used in the method does not volatilize, and the problem of ammonia volatilization is avoided. Besides, the leaching technology is simple in process, the method is friendly to the operation environment, and production cost is low.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

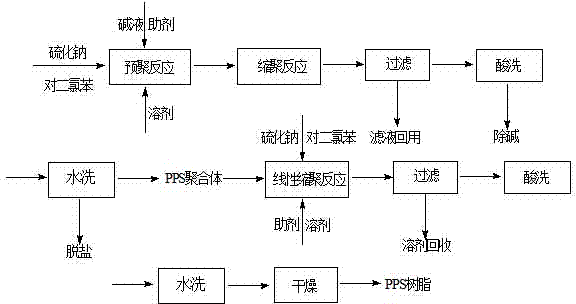

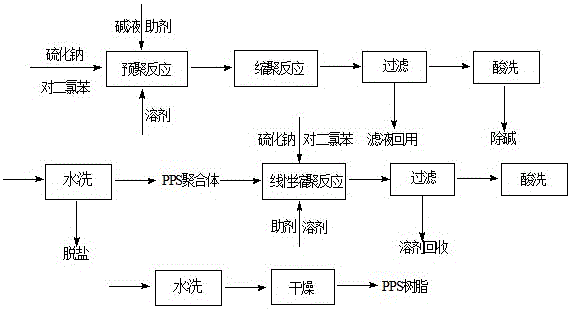

Method for synthesizing linear high molecular weight polyphenylene sulfide

The invention discloses a method for synthesizing linear high molecular weight polyphenylene sulfide and belongs to the technical field of chemical material. The method comprises the following steps: by taking sodium sulphide and dichloro diphenyl as raw materials, synthesizing the linear high molecular weight polyphenylene sulfide (PPP) resin through a solution polycondensation method and a secondary polymerization process in a compound solvent and a cosolvent system. The method is simple in process and convenient to operate; the product has a high molecular weight linear structure; in the whole polymerization process, the molecular weight is controllable. Compared with the prior art, the method has the advantages of good solvent system dissolving property, low salt content and easy separation. The monomer reactivity of the linear polymerization reaction is high and the chain extension is easy to process. The dosage of the alkali metal or the alkaline earth chloride is few and the metal ion can be easily washed. The linear high molecular weight polyphenylene sulfide does not have irritant or carcinogenic property and is environmentally friendly to operate.

Owner:CHANGZHOU UNIV

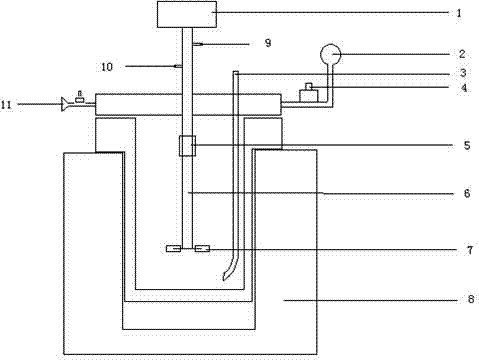

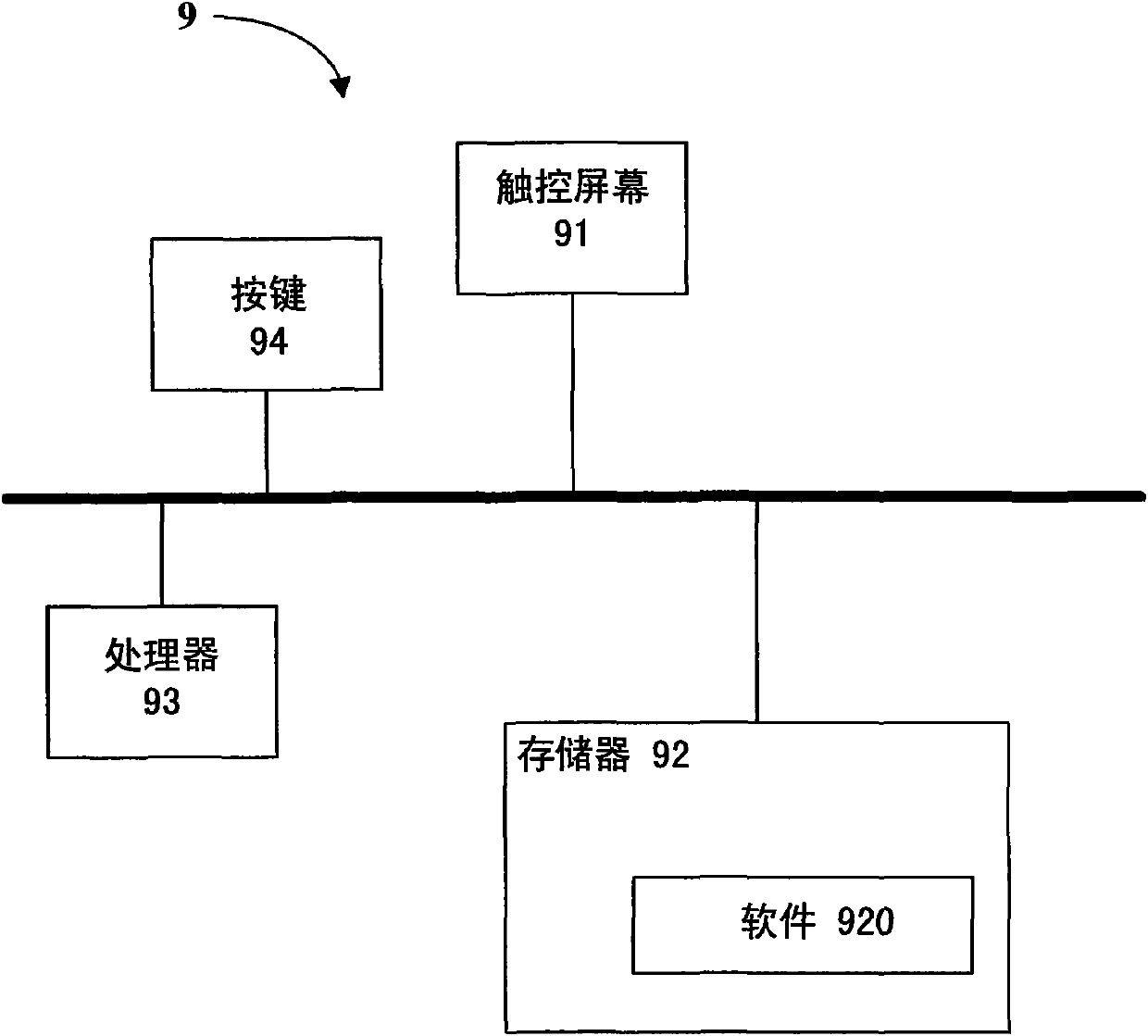

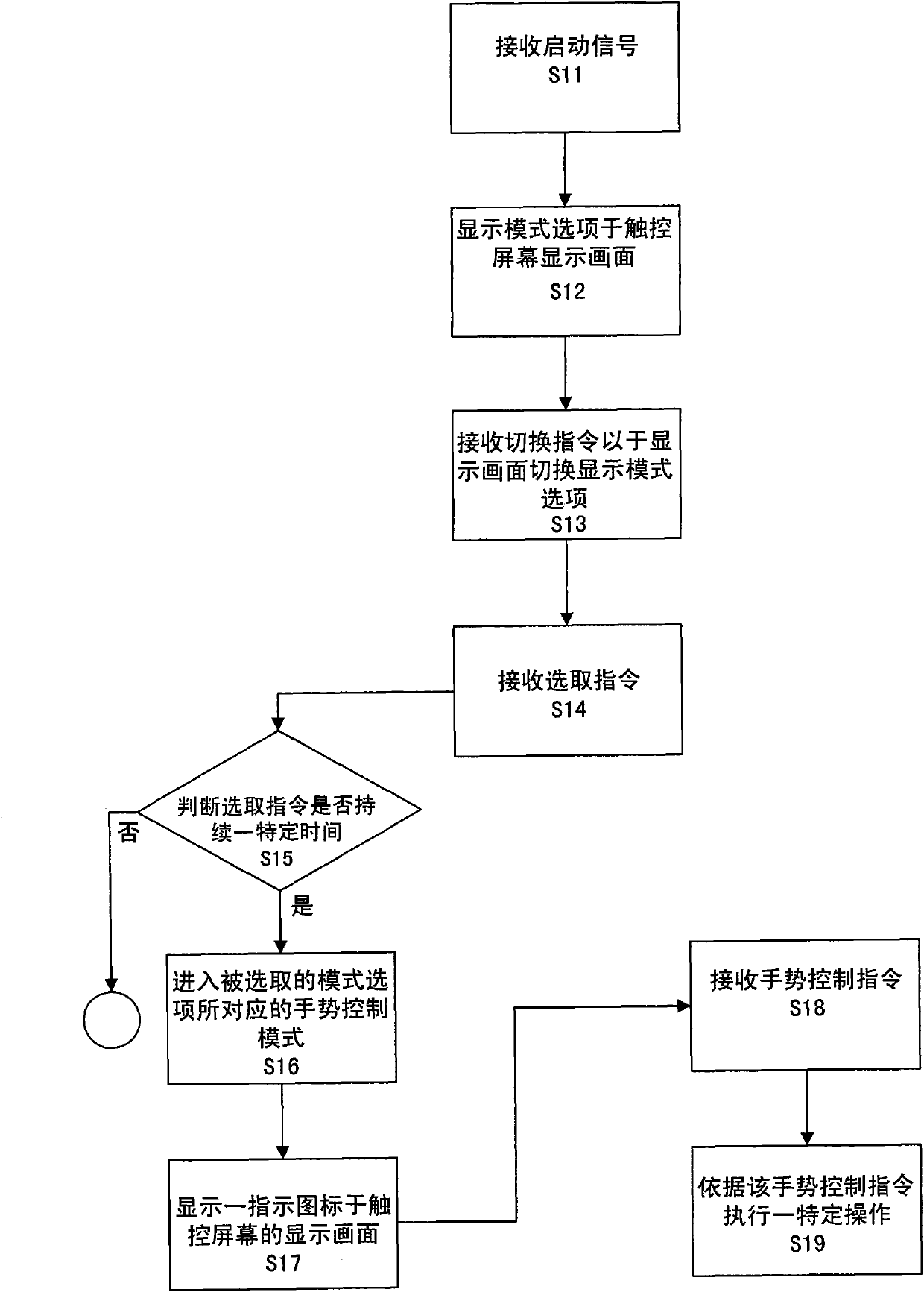

Control method for touch screen display frames

InactiveCN102023788AClear viewFull viewInput/output processes for data processingHuman–computer interactionOn-screen display

The invention relates to a control method for touch screen display frames, which comprises the following steps: displaying at least one mode selecting item in a touch screen display frame which is corresponded to a gesture control mode, receiving a selecting instruction which is selected aiming at one of the mode selecting items, entering into the gesture control mode corresponding to the selected mode selecting item according to the selecting instruction, receiving a gesture control instruction fit for the gesture control mode, and executing a specific operation according to the gesture control instruction. The method of the invention can help a user to clearly and completely view the frame content and can quickly and conveniently finish 360-degree continuous rotating operation at one time. At the same time, the holding and gesture operation of an electronic device are more stable and precise, error touch and faulty operation can be avoided, a finger for executing the gesture control instruction can be replaced by a touch pen, a friendly and flexible operation condition is provided, limitation on the support of multi-point touch is unnecessart, and the material cost is reduced.

Owner:ACER INC

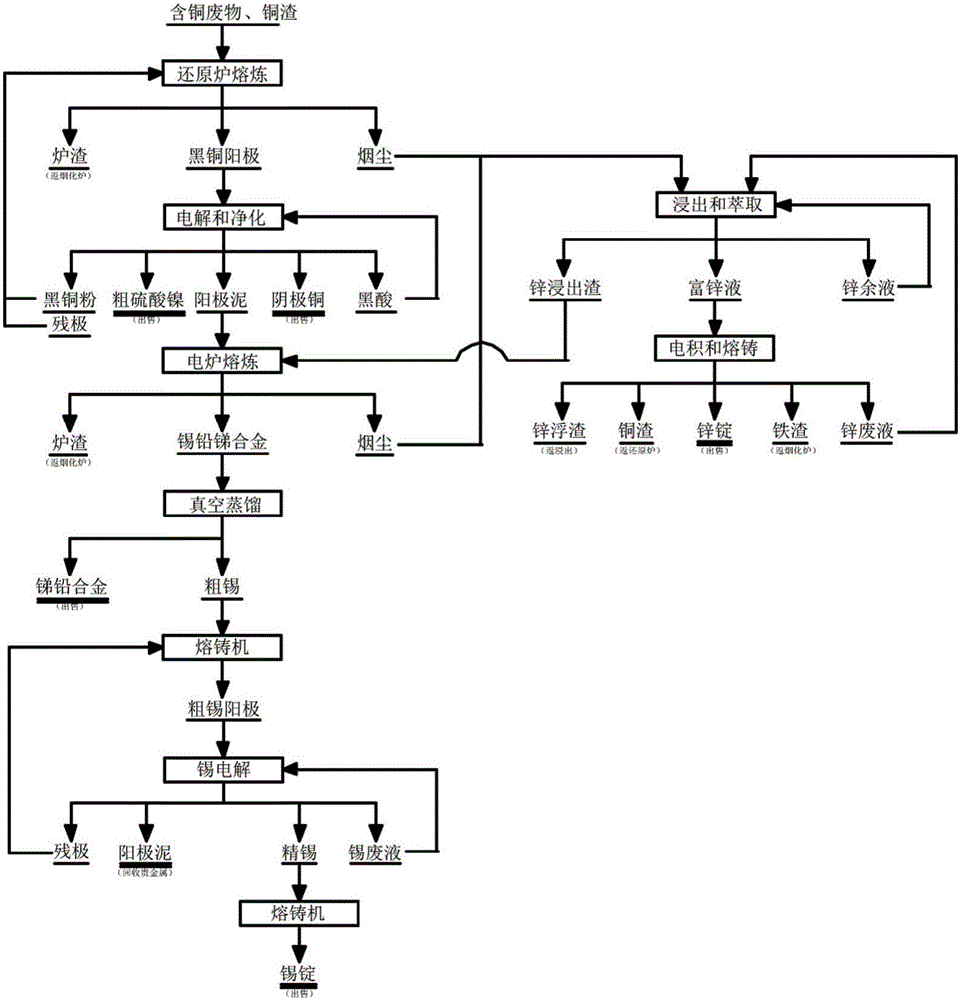

Full-path full-valence separation method for multifarious metal

ActiveCN105695744AInnovative technologyHigh recycling valuePhotography auxillary processesProcess efficiency improvementAntimonyRaw material

The invention discloses a full-path full-valence separation method for multifarious metal. Low-grade waste containing copper and copper slag serves as a raw material. The separation method comprises the following main steps that 1, the raw material is subjected to reduction smelting through a regeneration reduction furnace so that a black copper anode can be obtained, the raw material is subjected to electrolytic refining so that a metal cathode copper product and a crude nickel sulfate product can be obtained, and thus copper and nickel in the raw material are separated and recycled; 2, slag is leached out of copper anode mud and zinc and is subjected to reduction smelting through an electric furnace so that tin-lead-antimony alloy can be obtained, the tin-lead-antimony alloy is smelted through a vacuum furnace to be separated so that a antimony-lead alloy product and crude tin can be obtained, the crude tin is subjected to electrolytic refining so that refined tin can be obtained, that is, a tin ingot product is obtained, and hence tin, lead and antimony are separated and recycled; 3, a zinc ingot product is obtained by recycling smelting fume through a 'leaching- extraction- electrodeposition' method, so that the zinc, the tin and the lead are separated, and the zinc is recycled; and 4, tin anode mud is sent to a precious metal recycling factory as a precious metal enrichment material. According to the full-path full-valence separation method for the multifarious metal, the multifarious metal is completely separated, and remarkable economic benefits, environmental benefits and social benefits are achieved.

Owner:江西自立环保科技有限公司

Method for extracting vanadium by leaching vanadium-contained raw material roasting clinkers through ammonium phosphate

ActiveCN105714102AReduce leachingEasy to manufactureProcess efficiency improvementSelective leachingWastewater

The invention provides a method for extracting vanadium by leaching vanadium-contained raw material roasting clinkers through ammonium phosphate. The method includes the steps that a mixture of a vanadium-contained raw material and an additive is roasted, and the vanadium-contained raw material clinkers are obtained; and the vanadium-contained raw material clinkers are leached in an ammonium phosphate solution to extract vanadium, and vanadium extracting tailings and a vanadium-contained leaching agent are obtained after solid-liquid separation is carried out. According to the method, the vanadium selective leaching efficiency is high and can reach more than 90%; meanwhile, leaching of impurity element is less, preparation of products with the high-purity vanadium is facilitated, and brine waste is avoided; the leaching agent-ammonium phosphate solution used in the method does not volatilize, and the problem of ammonia gas volatilization is avoided; and in addition, the leaching technological process of the method is simple, the operation environment is friendly, and the production cost is low.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

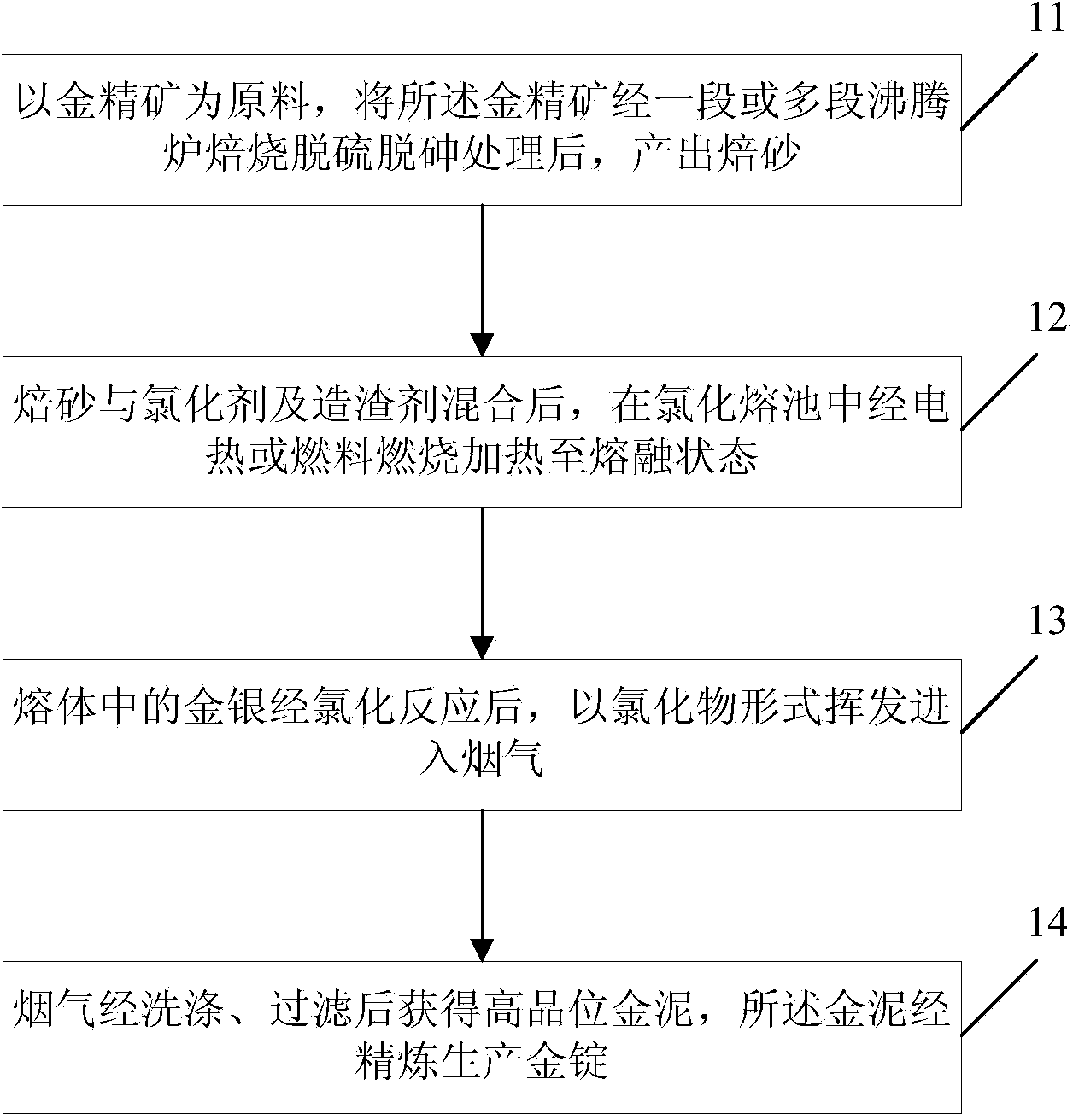

Method for extracting gold and silver from gold concentrate

The embodiment of the invention discloses a method for extracting gold and silver from a gold concentrate. The method includes: taking the gold concentrate as a raw material, subjecting the gold concentrate to roasting for sulfur and arsenic removal treatment by one or more sections of fluidized bed roasters so as to obtain calcine; mixing the calcine with a chlorinating agent and a slag former, heating the mixture to a molten state in a chlorination molten pool by electric heating or fuel burning, and letting the gold and silver in the melt volatilize into flue gas in the form of a chloride after chlorination reaction; and washing and filtering the flue gas to obtain high grade gold mud, and refining the gold mud to produce a gold ingot. The method has the advantages of higher gold and silver recovery rates, strong raw material adaptability, short technological process, low energy consumption, and friendlier operation environment.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY +1

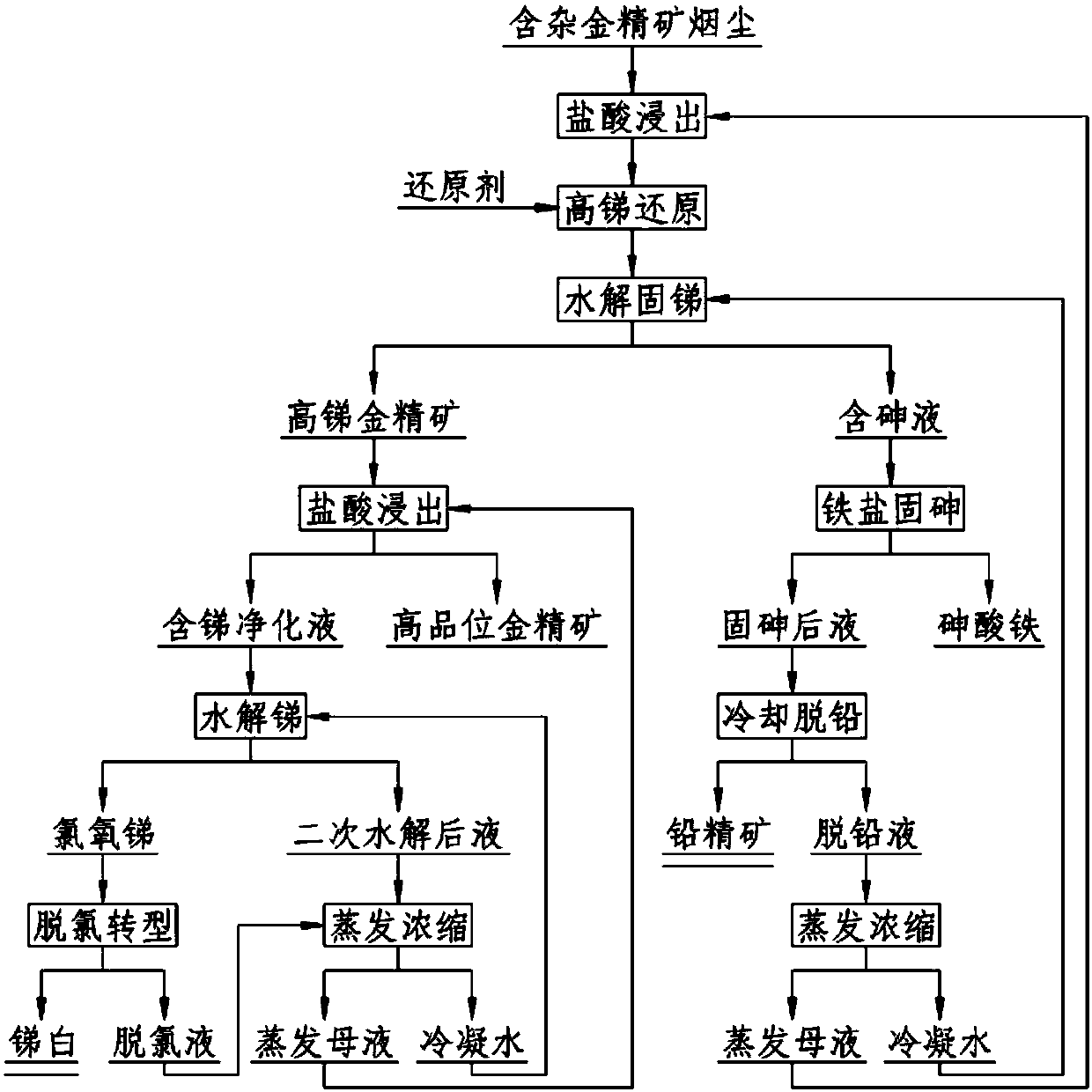

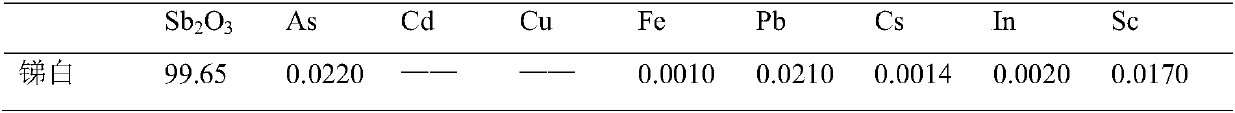

Comprehensive treatment method for smelting dust containing miscellaneous gold concentrate

ActiveCN108034831ASolve difficult industry problemsEasy to produceIron compoundsProcess efficiency improvementArsenatePregnant leach solution

The invention discloses a comprehensive treatment method for smelting dust containing miscellaneous gold concentrate and belongs to the technical field of precious metal pyrometallurgy. The comprehensive treatment method for the smelting dust containing the miscellaneous gold concentrate comprises the steps that firstly, the smelting dust is subjected to primary hydrochloric acid leaching, leachedslurry is subjected to high-price antimony reduction and hydrolysis antimony fixing, high-antimony gold concentrate and primarily-hydrolyzed liquid are obtained, secondary hydrochloric acid leachingis conducted on the high-antimony gold concentrate, high-grade gold concentrate with low impurities and secondary lixivium are obtained, high-grade oxychloride and secondarily-hydrolyzed liquid are obtained after hydrolysis is conducted on the secondary lixivium, dechlorinating transformation is conducted on the oxychloride, and then an antimony white terminal product is obtained; and a molysite arsenic fixing process is adopted for arsenic-containing liquid, and stable low-toxicity arsenic compound ferric arsenate and arsenic-removed liquid are obtained. By the adoption of the method, the smelting dust containing the miscellaneous gold concentrate is treated, the precise metal antimony can be effectively recovered, and the harmful element arsenate is fixed, so that the industrial problemthat arsenic and antimony dust is difficult to treat is solved.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Environment-friendly sulfur-containing gold leaching reagent and preparation method thereof

The invention discloses an environment-friendly sulfur-containing gold leaching reagent and a preparation method thereof. The preparation method of the gold leaching reagent comprises steps as follows: a sulfur-containing substance is taken as a raw material and dissolved in water, an oxidizing agent is added for oxidation, average chemical valence of sulfur in an obtained solution is controlled to be 2-3, then sulfide and / or polysulfide is removed, filtering is performed, a filtrate is collected, and a liquid gold leaching reagent is obtained. The sulfur-containing substance is subjected to oxidation operation, the degree of oxidation of the sulfur-containing substance is controlled, then sulfide and / or polysulfide is removed, so that the use quantity of the obtained gold leaching reagent during gold leaching is substantially reduced, and concentration of the gold leaching reagent during gold leaching at the normal temperature and under the normal pressure is 0.2-20 g / L in terms of a solid gold leaching reagent; the obtained gold leaching reagent is free of cyanide, and the operation is environment-friendly.

Owner:CHINA NONFERROUS METAL (GUILIN) GEOLOGY & MINING CO LTD

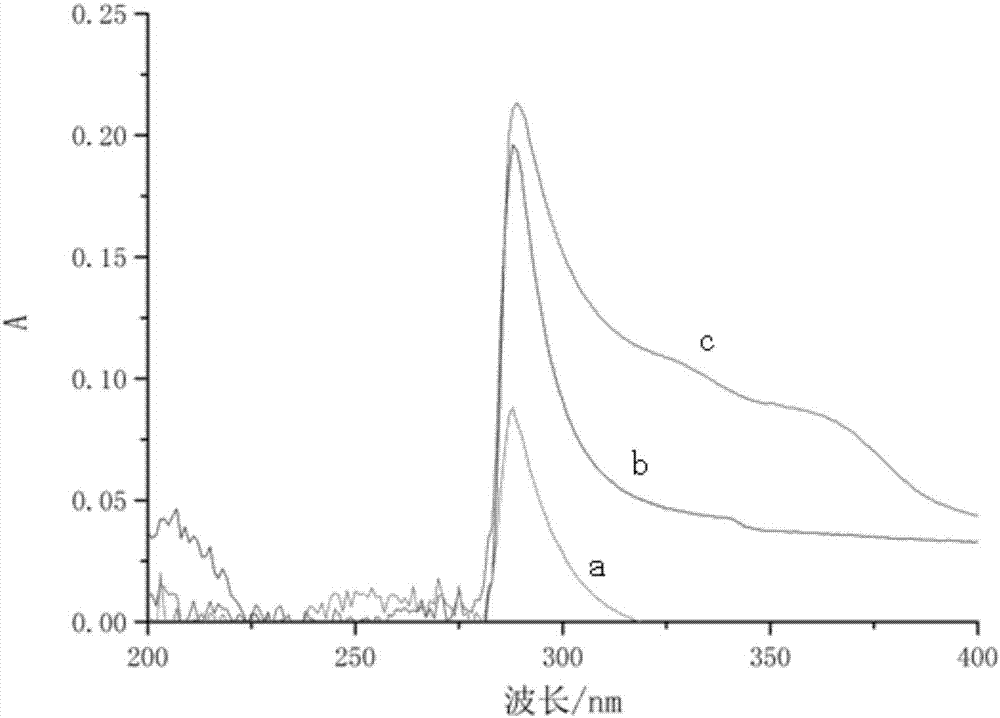

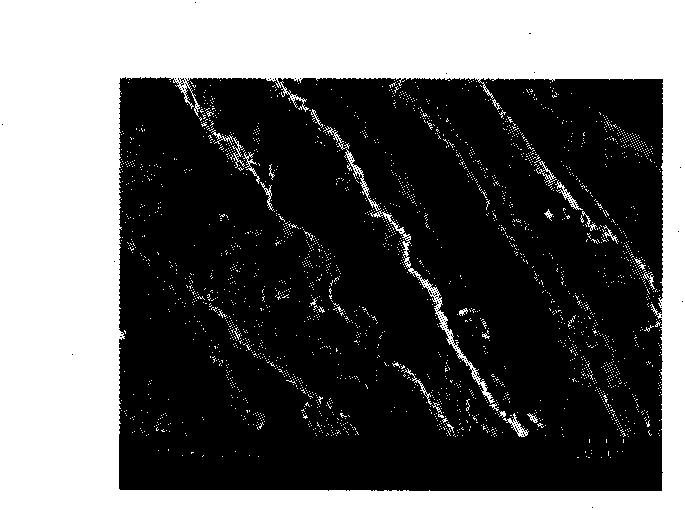

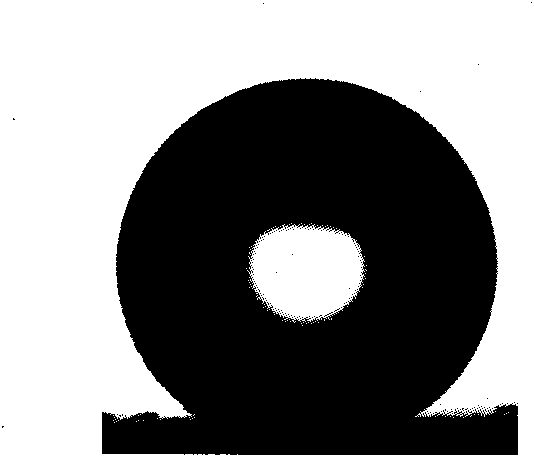

Method for preparing super-hydrophobic conductive cellulose fabrics by CNT (carbon nano tube) finishing technology

InactiveCN102605608ARealize industrialized mass productionEasy to operateVegetal fibresProduction lineCellulose

The invention provides a method for preparing super-hydrophobic conductive cellulose fabrics by the CNT (carbon nano tube) finishing technology, which is characterized in that the method comprises the following steps: 1, preparing CNT dispersion liquid; 2, performing dipping-rolling treatment on cellulose fabrics; 3, putting treated samples in an oven for drying; and 4, repeating the step 2 and the step 3 until the cellulose fabrics attain prospective water repellency and electrical conductivity. The method provided by the invention uses a one-step method to realize the finishing of the cellulose fabrics on super water-repelling property and electric conduction, and has the following advantages: 1, simplicity and convenience in operation, and operating-environment friendliness; 2, no need for expensive equipment; and 3, the capacity of realizing industrialized production on the existing dyeing and finishing production line and the sizing production line.

Owner:DONGHUA UNIV

Method for separating halogen ions such as chlorine, fluorine and the like from sulfate

PendingCN109650628AFriendly operating environmentGuaranteed uptimeFatty/oily/floating substances removal devicesAlkali metal sulfite/sulfate purificationHalogenSulfate

The invention relates to a method for separating halogen ions such as chlorine, fluorine and the like from sulfate, which comprises the following steps: pretreating stock solution, namely performing pretreatment such as conditioning, removing oil, removing suspended matters and the like on the sulfate stock solution; separating by using a nanofiltration membrane, and separating halogen ions such as chlorine, fluorine and the like in sulfate by using the nanofiltration membrane; treating the nanofiltration retentate, wherein the nanofiltration retentate is sulfate solution separated from halogen ions such as chlorine, fluorine and the like, and the nanofiltration retentate returns to a sulfate circulating system or a production system of a main device; treating the nanofiltration permeate solution, wherein the nanofiltration permeate solution is a separated halide solution such as chlorine, fluorine and the like, and concentrating and crystallizing the permeate solution to prepare a halide product such as chlorine, fluorine and the like. The method comprises the following steps: separating halogen ions such as chlorine, fluorine and the like in sulfate by using a nanofiltration membrane, and selecting the nanofiltration membrane with the aperture of 0.1nm-8.5nm and high separation efficiency of monovalent ions and multivalent ions, thereby reducing the halogen ions such as chlorine, fluorine and the like in the sulfate.

Owner:南京圣创科技有限公司

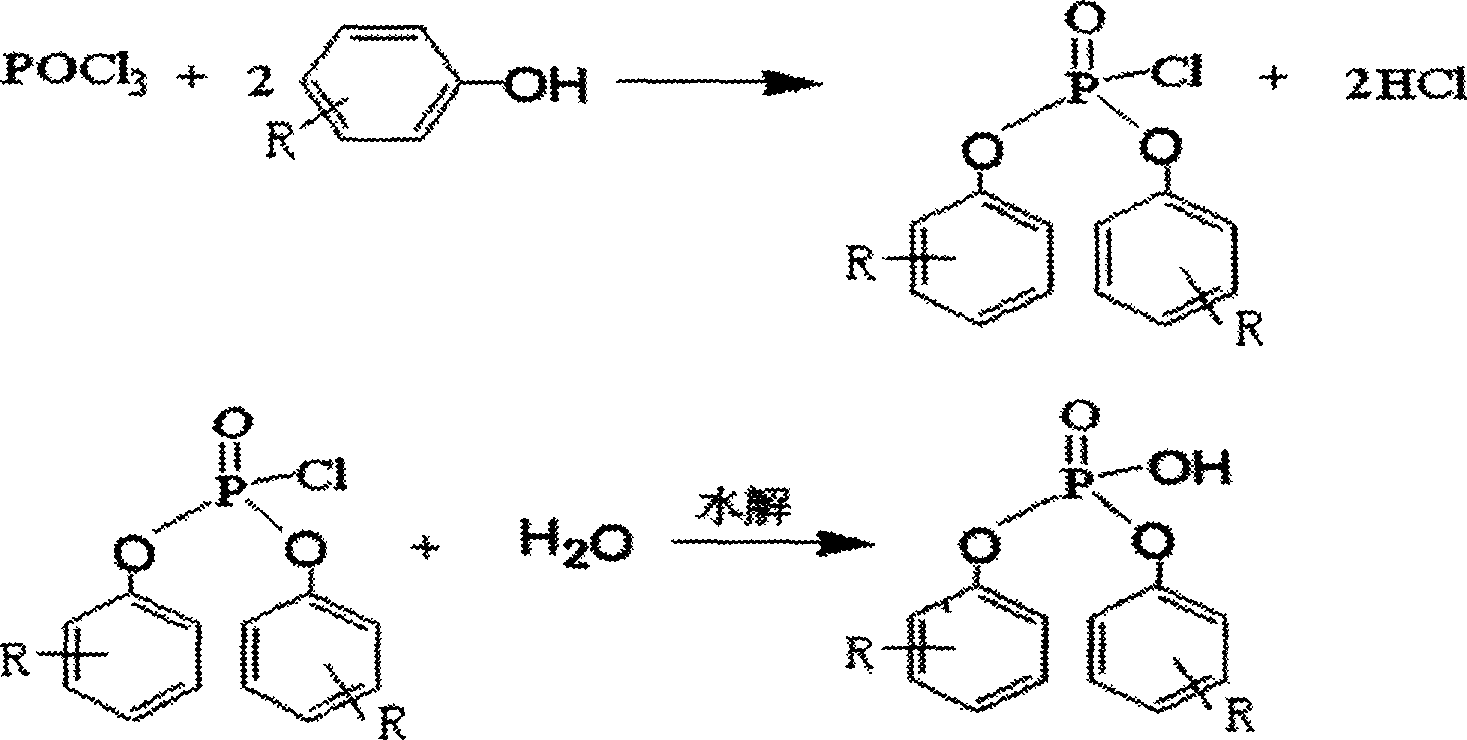

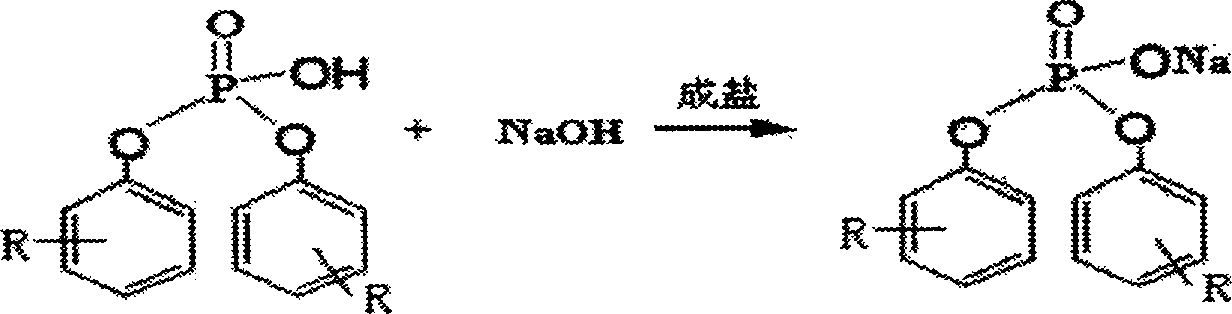

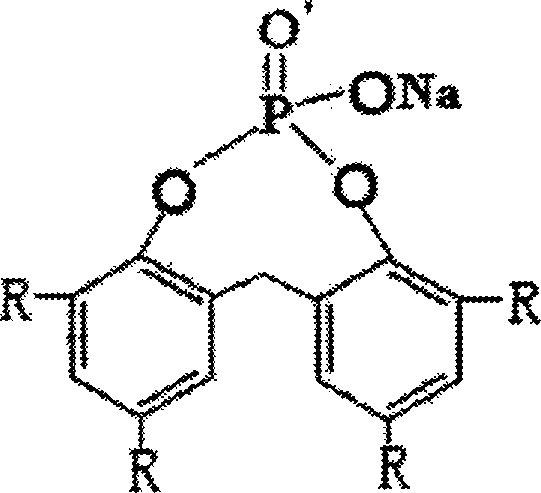

Preparation method of substituted diaryl phosphate

InactiveCN1786006AMoisture requirements are not criticalFriendly operating environmentPhosphorus organic compoundsPhosphateSolvent

The present invention relates to the field of organic and high-molecular chemistry, and discloses a preparation method of substituted diaryl phosphate. It is characterized by that said invention uses substituted phenol or substituted diaryl bisphenol as raw material, in the presence of inorganic alkali and non-toxic solvent said invention makes three steps of phenol treatment, condensation reaction and direct alkali-adding aqueous solution salt formation be implemented in one reaction container.

Owner:SUN YAT SEN UNIV

Heat-resistant phenolic aerogel and preparation method thereof

ActiveCN111234299AHigh network skeleton strengthLow priceBulk chemical productionHexamethylenetetraminePhenolic aldehyde

The invention relates to a preparation method of heat-resistant phenolic aerogel. The preparation method comprises the following steps: S1, synthesizing boron-modified phenolic resin; S2, mixing the boron-modified phenolic resin with a curing accelerator and a solvent to obtain a phenolic resin solution; S3, gelatinizing the phenolic resin solution under a closed condition to obtain phenolic aldehyde wet gel; and S4, drying the phenolic aldehyde wet gel at normal pressure to obtain the heat-resistant phenolic aldehyde aerogel. The heat-resistant phenolic aerogel is prepared by adopting a sol-gel-normal-pressure drying process, so that the prepared phenolic aerogel has the advantages of high heat resistance, high network skeleton strength and the like through boron modification; the raw materials in the preparation method are all general chemical raw materials and are low in price; a curing agent hexamethylenetetramine does not need to be added in the preparation process, so that no ammonia gas is released in the curing process, and the operation environment is friendly.

Owner:SUZHOU TUNABLE MATERIALS TECH CO LTD

Recovery liquid for ion exchange resin polluted by iron

InactiveCN101791581ALess irritatingFriendly operating environmentIon-exchanger regenerationCation exchangersInorganic saltsEthylene diamine

The invention discloses recovery liquid for ion exchange resin polluted by iron, which comprises the following materials by weight percent: 20-30 percent of acid substance, 10-20 percent of inorganic salt, 40-50 percent of reducing agent and 10-20 percent of disodium ethylene diamine tetraacetate (EDTA). In the material components, the acid substance is hydrochloric acid; the inorganic salt is sodium chloride; the reducing agent is hydroxylamine hydrochloride, orthophenanthroline or a mixture of the hydroxylamine hydrochloride and the orthophenanthroline; and the complexing agent is EDTA or sodium salt thereof. The recovery liquid has the advantages of little stimulation to a human body, good recovery effect, and the like and can effectively carry out recovery to the iron pollution of the resin.

Owner:SHAANXI ELECTRIC POWER RES INST

Wear-resisting sole rubber material and preparation method thereof

The invention discloses a wear-resisting sole rubber material and a preparation method thereof. The wear-resisting sole rubber material is prepared from the following components in parts by weight: 50to 65 parts of a rubber composition, 1 to 4 parts of zinc oxide, 2 to 4 parts of magnesium oxide, 20 to 30 parts of a reinforcing agent, 1.2 to 2 parts of an anti-ageing agent, 0.2 to 0.6 part of anaccelerant, 1 to 3 parts of stearic acid, 2 to 4 parts of a wear-resisting agent, 1.5 to 2.1 parts of a dispersant, 3 to 5 parts of an adhesive and 1.5 to 3 parts of operating oil; the rubber composition is prepared from natural rubber, cis-butadiene rubber and butadiene styrene rubber. The wear-resisting sole rubber material disclosed by the invention has the advantages of no odor, wearing resistance and folding resistance, a sole is not broken and the material has a glossy and beautiful appearance; the wearing resistance of the rubber material is greater than or equal to 120 and the servicelife reaches 3 years or more, so that the rubber material meets environment-friendly requirements. The wear-resisting sole rubber material disclosed by the invention is suitable for batch production,the operability is improved and the operation is more environmentally friendly.

Owner:鹤山市名鹤鞋材有限公司

Method for extracting vanadium from ammonium phosphate leaching vanadium containing raw clinker

InactiveCN105671339AReduce leachingEasy to manufactureProcess efficiency improvementSelective leachingWastewater

The invention provides a method for extracting vanadium from ammonium phosphate leaching vanadium containing raw clinker. The method comprises the steps that a vanadium containing raw material is subjected to blanking roasting to obtain the vanadium containing raw clinker; the vanadium containing raw clinker is leached in an ammonium phosphate solution for vanadium extraction; and after solid-liquid separation, leaching residues and a vanadium containing solution are obtained. According to the method, the selective leaching rate of vanadium is high and can reach 90% or above; meanwhile, few impurity elements are leached out, preparation of a high-purity vanadium product is facilitated, and no salt containing waste water is generated; a leaching agent, the ammonium phosphate solution, adopted in the method does not volatilize, so that the problem of ammonia gas volatilization is avoided; and in addition, the method is simple in leaching technological process, friendly in operation environment and low in production cost.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

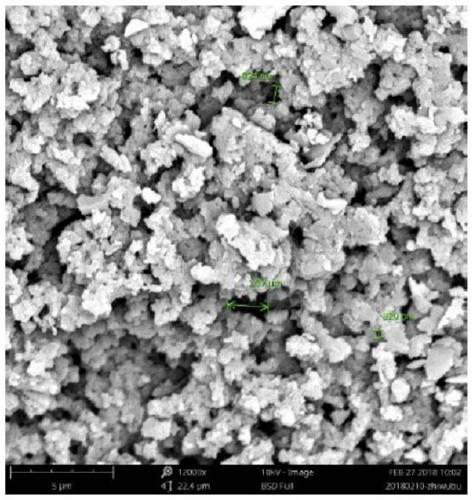

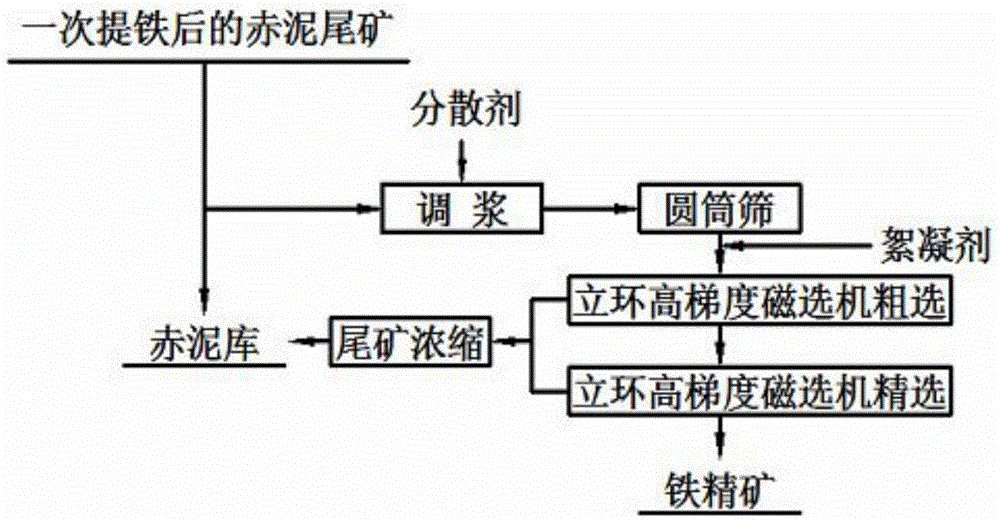

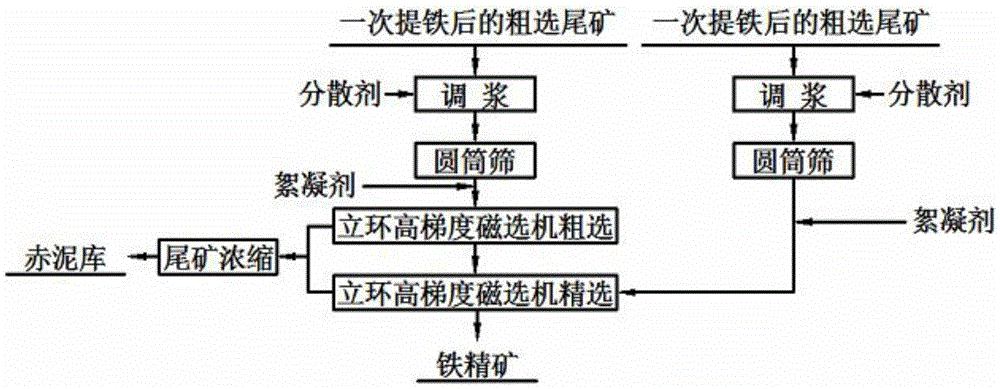

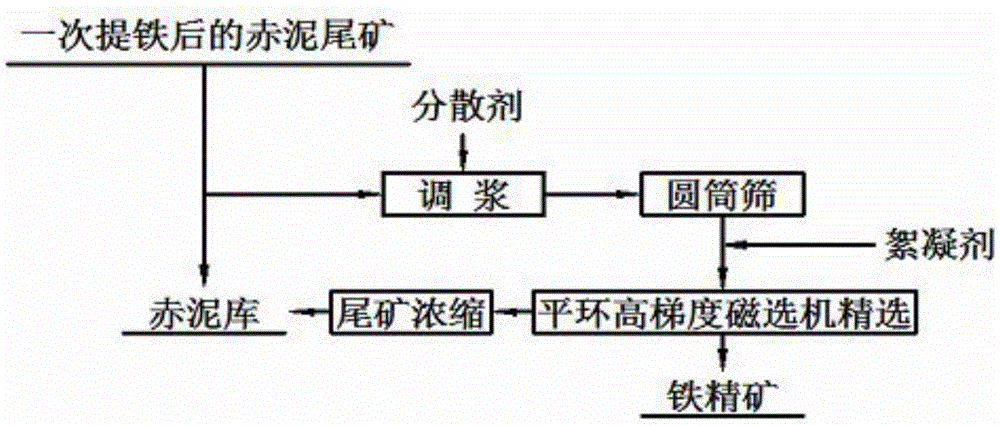

Method for extracting micro-fine-particle iron ore concentrate from tailings obtained after primary iron separation

InactiveCN105536979AHigh yieldHigh recovery rateHigh gradient magnetic separatorsWet separationSlagRed mud

The invention discloses a method for extracting micro-fine-particle iron ore concentrates from tailings obtained after primary iron separation. The method includes the following steps that red mud tailings obtained after primary iron separation are subjected to roughing and concentration of a high-gradient magnetic separator to obtain coarse-particle iron ore concentrates, wherein a large number of micro-fine-particle iron ore concentrates are contained in the tailings obtained after roughing and the tailings obtained after concentration, and an NSF dispersing agent is added for slurry mixing; a polyacrylamide A type flocculant is added before magnetic separation, roughing and concentration are conducted through a vertical-ring high-gradient magnetic separator or one-time beneficiation is conducted through a flat-ring high-gradient magnetic separator, and the iron ore concentrates are obtained; and the tailings are condensed through a thickener and then pumped into a red mud storeroom to be piled, supernatant of the thickener is used for cyclic slurry mixing and ore flushing in a system, and tailing slag and water are not discharged outside. The method is suitable for tailings containing more than 15% of Fe and with the slurry concentration ranging from 30%-45% and has the beneficial effects that the technology is simple, operation is environment-friendly, and adaptability is high.

Owner:陈均宁

Calcium remover for aluminum alloys as well as preparation and use method of calcium remover

The invention relates to the field of melting of aluminum alloys, in particular to a calcium remover for aluminum alloys as well as a preparation and use method of the calcium remover. The calcium remover for the aluminum alloys is prepared from the following components in parts by mass: 60-80 parts of calcium phosphate, and 20-40 parts of fused salt. The calcium remover is prepared through the following steps of mixing magnesium chloride with potassium chloride and sodium chloride, performing heating to make the fused salt, adding the calcium phosphate according to the required mass into the fused salt, performing heating, and performing heat insulation so as to obtain a melted calcium remover; or casting the melted calcium remover in a mold, performing cooling and solidifying to obtain a solid calcium remover, and performing sealing packaging for standby application. Compared with the prior art, the calcium remover for the aluminum alloys, disclosed by the invention, is friendly in operating environment, flexible in using method, broad in application scope, and high in calcium removing efficiency. When the calcium remover which is 0.5% of melted aluminum alloy is added, the content of calcium in the aluminum alloys can be reduced from 0.015% to 0.002%.

Owner:BEIJING JIAOTONG UNIV

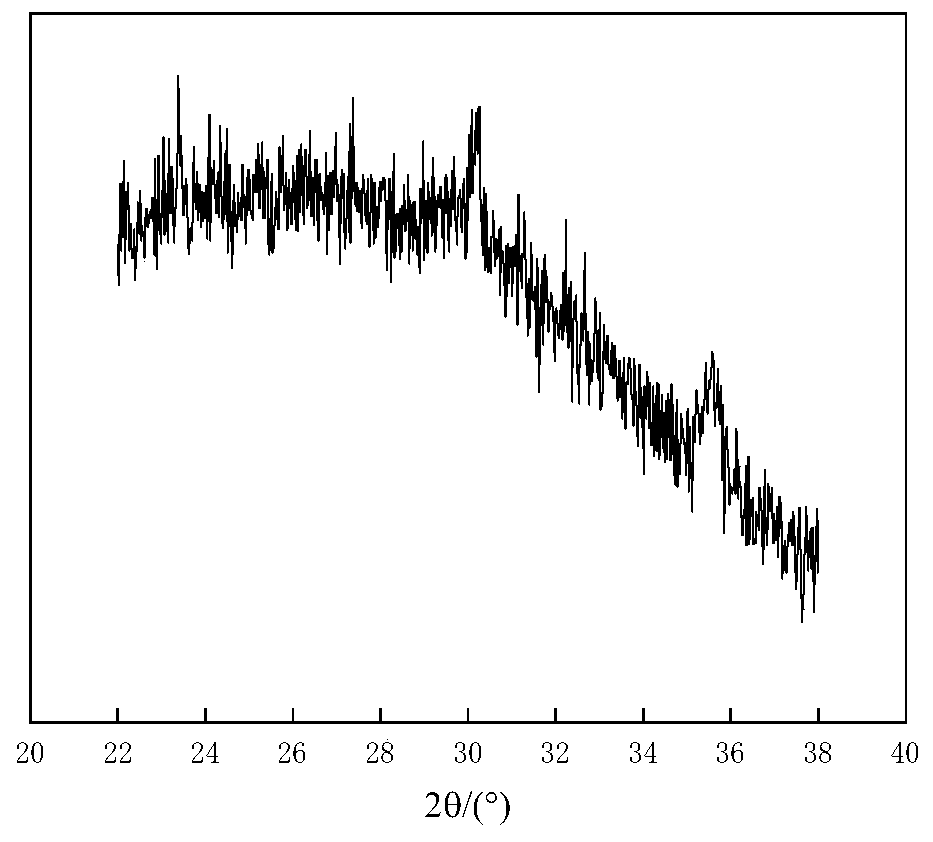

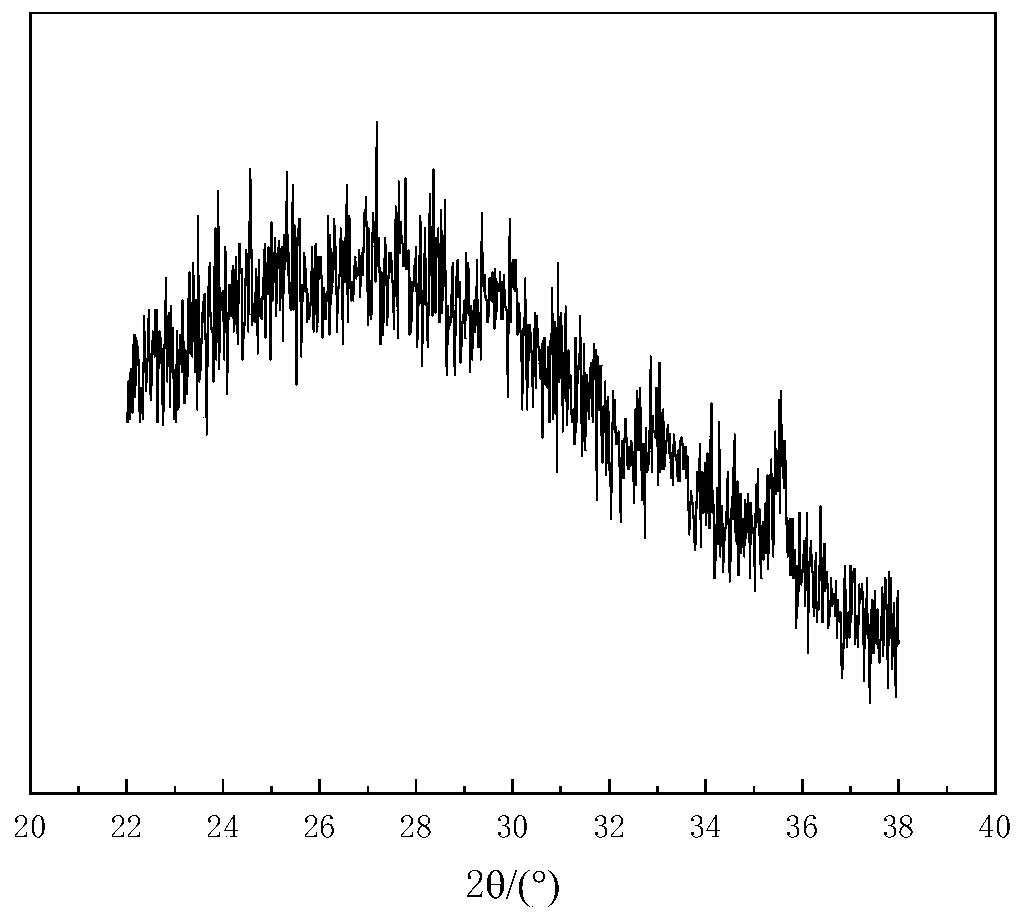

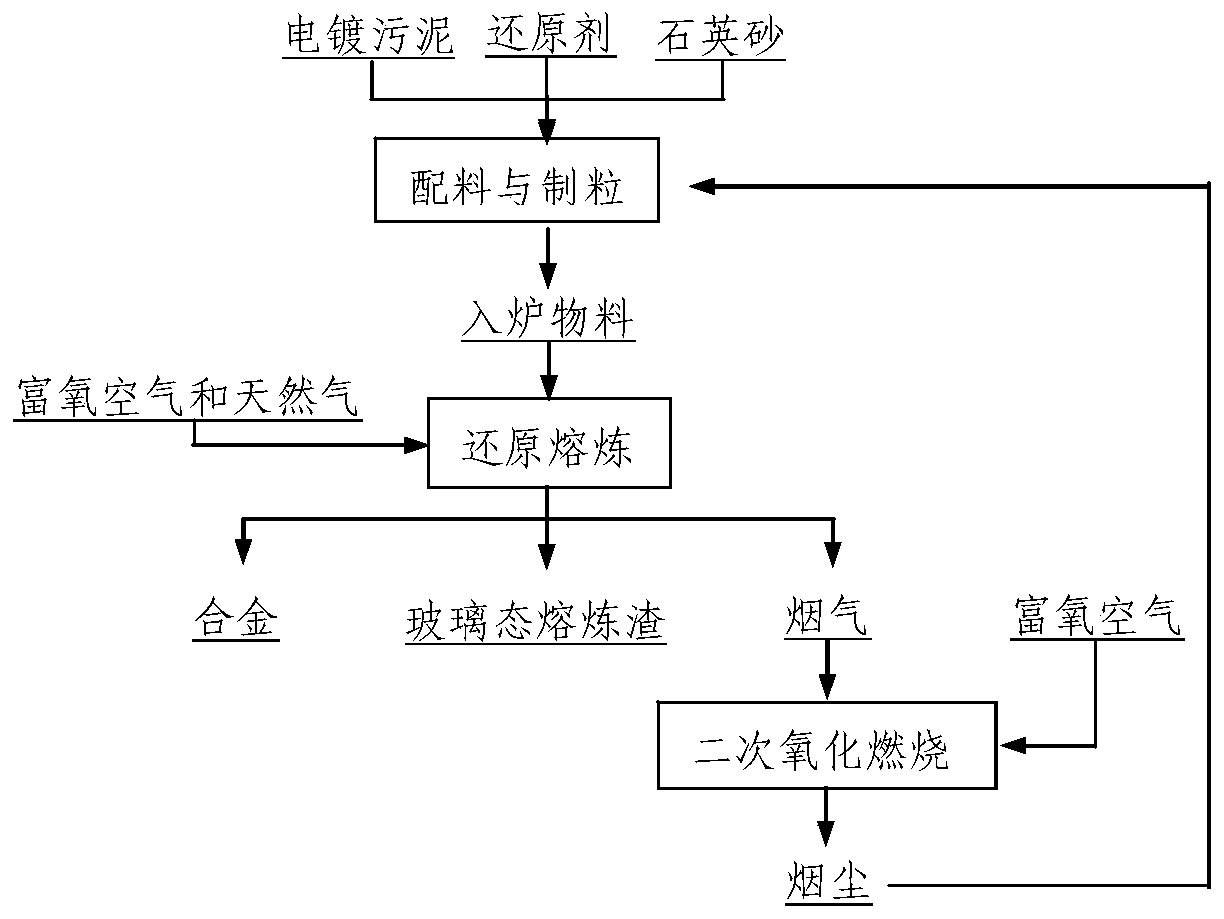

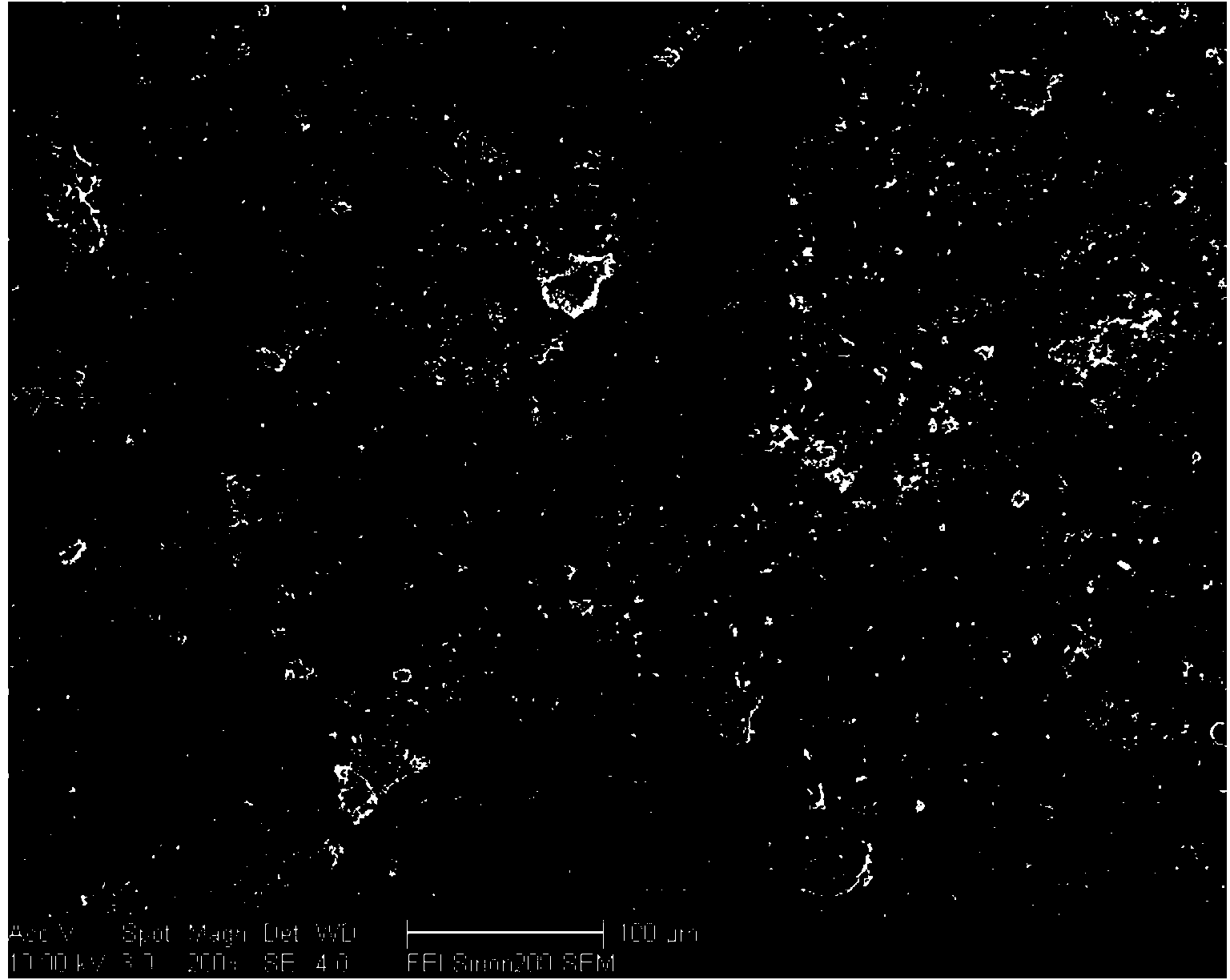

Method for harmlessly treating electroplating sludge

ActiveCN110951966AGood recycling benefitsReduce labor intensityCement productionProcess efficiency improvementSlagSludge

The invention relates to a method for harmlessly treating electroplating sludge. The method comprises the following steps that the electroplating sludge, a reducing agent and quartz sand are proportioned according to a certain ratio, and mixing and granulating are carried out in a granulator to obtain a furnace-in material; and the furnace-in material is added into a smelting furnace, natural gasand oxygen are introduced, reducing atmosphere is controlled to carry out reduction smelting, and glassy-state smelting slag and alloy are obtained. According to the method, the obtained smelting slagis no longer hazardous waste with leaching toxicity characteristics, and can be used as a building material and the like; and the alloy is further separated and purified, valuable metal in the electroplating sludge can be efficiently recovered through reduction smelting, the recovery rate of copper and nickel can reach 90% or above, the valuable metal is good in recovery benefit, low in labor intensity, short in treatment time, friendly in operation environment, and mature and reliable in process.

Owner:CENT SOUTH UNIV

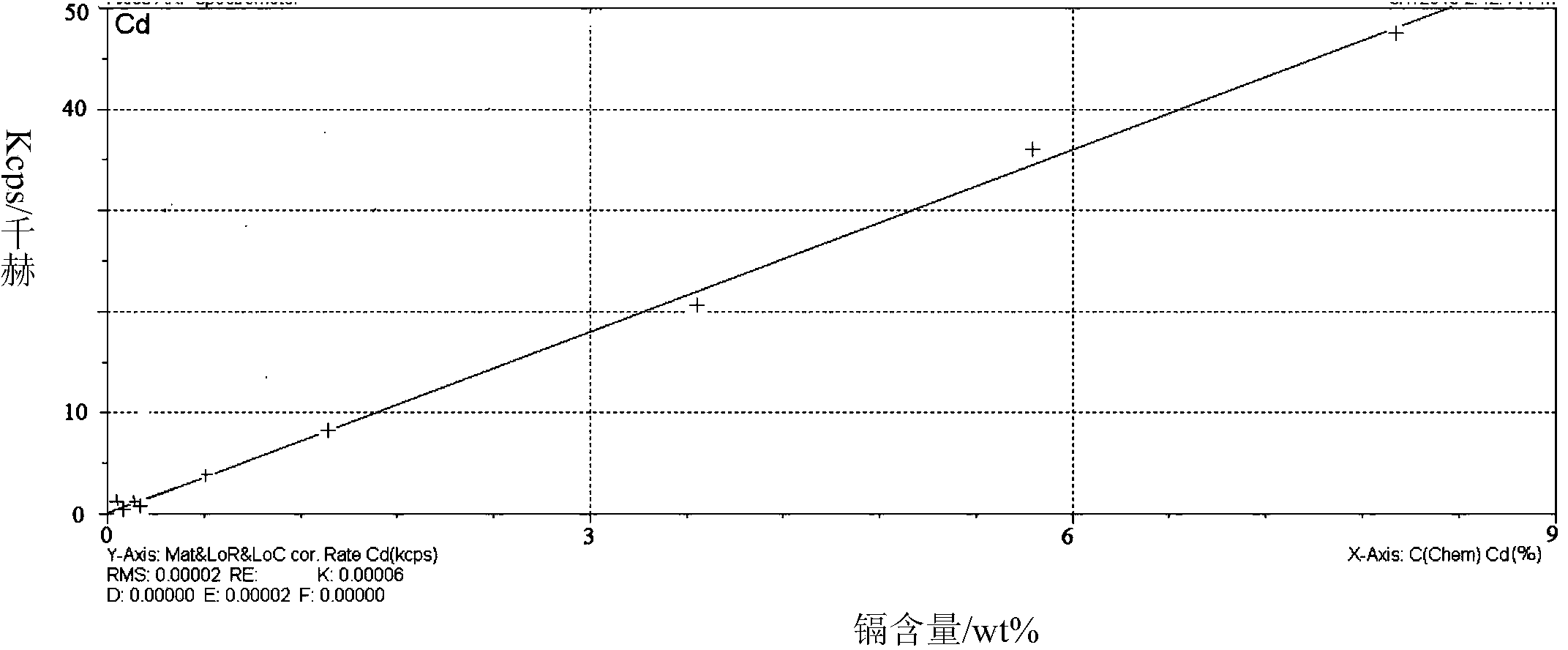

Preparation method for cadmium-containing ceramic glaze standard sample

InactiveCN103454132AAccurate cadmium content determinationAccurate quantitative analysisPreparing sample for investigationStandard samplesCeramic industry

The invention relates to a preparation method for a cadmium-containing ceramic glaze standard sample. The cadmium-containing ceramic glaze standard sample is obtained by the steps of mixing, grinding, granulating, forming and sintering. The cadmium-containing ceramic glaze standard sample prepared by the method disclosed by the invention has an accurate cadmium content fixed value; the fluctuation range of a cadmium content measurement result is small; the quantitative analysis of the cadmium in glaze of a ceramic product is accurate; the preparation steps are simple; the operation environment is friendly; the popularization and the application are facilitated. According to the preparation method, the problem, which exists in the ceramic industry for many years, that accurate quantitative analysis cannot be performed on the cadmium content of the glaze of the ceramic product and the problem of no standard sample or insufficient standard samples of the ceramic glaze to be detected can be solved; a powerful technical measure is provided for scientific detection and analysis of the cadmium content of a glaze layer of the ceramic product.

Owner:INTEGRATION TECH SERVICE CENT OF ZIBO ENTRY EXIT INSPECTION & QUARANTINE BUREAU

Production process for recovering uranium and molybdenum from sedovite acid leaching tailings

InactiveCN107746967AIncrease profitEmission reductionProcess efficiency improvementSulfurCalcination

The present invention discloses a production process for recovering uranium and molybdenum from sedovite acid leaching tailings. The production process comprises: carrying out breaking and fine grinding on dried sedovite acid leaching tailings, uniformly mixing the grinded sedovite acid leaching tailings and an additive, adding water, granulating, carrying out high temperature calcination on the ore pellets, cooling the calcined ore, piling, and leaching by spraying a sulfuric acid solution. According to the present invention, the ore and the sulfur fixing agent are uniformly mixed, and granulation is performed, such that no smoke dust is generated during the calcination, more than 98% of sulfur is cured in the ore, the calcined ore can be subjected to pile leaching so as to eliminate thesolid-liquid separation and achieve the high comprehensive utilization of resources, and the uranium and molybdenum resources are comprehensively recycled, wherein the uranium leaching rate and the molybdenum leaching rate respectively are more than 65% and more than 75%; and the production process has high economic value, the leached tailings can be directly piled and stored in the tailings warehouse after the neutralization, and the whole process is environment-friendly and pollution-free.

Owner:BEIJING RESEARCH INSTITUTE OF CHEMICAL ENGINEERING AND METALLURGY

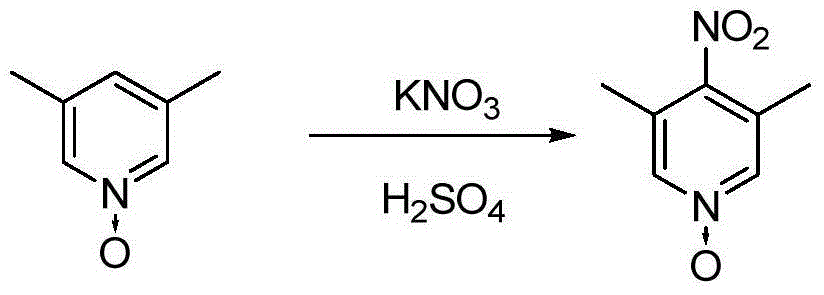

Synthesis method of 3,5-dimethyl-4-nitropyridine-N-oxide

ActiveCN104557693AAvoid it happening againShort reaction timeOrganic chemistryChemical industryPotassium nitrate

The invention discloses a synthesis method of 3,5-dimethyl-4-nitropyridine-N-oxide, and belongs to the field of chemical industry. The method comprises the following steps: mixing 3,5-dimethyl pyridine-N-oxide with concentrated sulfuric acid so as to form a mixed liquid, dropwise adding a sulfuric acid solution of potassium nitrate to the mixed liquid at 0-60 DEG C, and reacting at 60-120 DEG C for 0.5-12hr so as to obtain 3,5-dimethyl-4-nitropyridine-N-oxide. The synthesis method of the 3,5-dimethyl-4-nitropyridine-N-oxide, by replacing concentrated nitric acid or fuming nitric acid with the potassium nitrate as a nitrating reagent, can be used for greatly shortening reaction time and avoiding the generation of brown smoke during reacting and post-processing, an operating environment is friendly, and the problem of environmental pollution caused by the massive use of nitric acid is relieved; and meanwhile, reaction yield is improved as well; since environmental issue is increasingly emphasized nowadays, the 3,5-dimethyl-4-nitropyridine-N-oxide can be used for better replacing nitric acid as a nitrating reagent to complete a nitrating reaction.

Owner:JIANGSU ZHONGBANG PHARMA

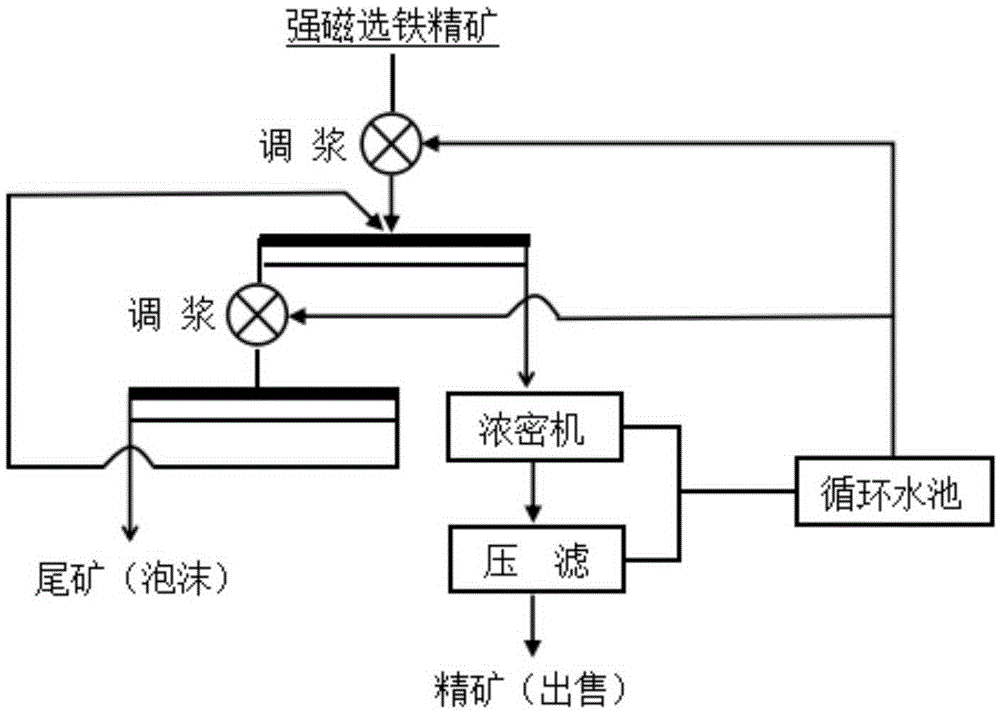

Flotation method for improving grade of flocculent iron ore concentrate

The invention discloses a flotation method for improving the grade of a flocculent iron ore concentrate. The flotation method comprises the following steps of carrying out magnetic separation to obtain 42-54% of flocculent iron ore concentrate powder; then, carrying out slurry mixing and wet grinding, and then, carrying out roughing-refining-sweeping reverse flotation process flow under an alkaline system to obtain 55-64% of high-grade iron ore concentrate; and concentrating the iron ore concentrate by using a thickener, carrying out filter pressing, then, selling, carrying out internal recycling and slurry mixing on filter pressing water and a supernatant, and delivering tailings to a cement plant. The flotation method is suitable for 42-54% of flocculent iron ore concentrate powder with the ore slurry concentration of 30-50% and has the characteristics of simple process, environment friendliness in operation, water recycle and no wastewater and waste gas discharge; and the tailings are suitable for being used as ingredients in the cement plant.

Owner:陈均宁

Clean production method for recovering uranium and molybdenum from wrapped uranium and molybdenum ores

The invention discloses a clean production method for recovering uranium and molybdenum from wrapped uranium and molybdenum ores and belongs to the field of chemical engineering and metallurgy. The clean production method comprises the following steps of evenly mixing the crushed wrapped uranium and molybdenum ores with additives, and then adding water for pelletizing; conveying the pelletized ores into a rotary kiln for roasting; cooling the roasted ores and then conducting heaping; and then spraying a leaching agent to conduct leaching. According to the clean production method for recoveringthe uranium and molybdenum from the wrapped uranium and molybdenum ores, the ores and a sulfur-fixing agent are mixed evenly and are subjected to pelletizing; in the roasting process, not smoke and dust are generated; 95% or more of sulfur can be solidified in the ores; the roasted ores can be subjected to heap leaching; the leaching rates of the uranium and molybdenum in the ores can reach up to90% and 80% or more correspondingly; the solid-liquid separation step is omitted; the solid content of a leaching solution is low, and the leaching solution can be directly used for subsequent extraction separation. The clean production method has the advantages of being reasonable in technological process, high in production efficiency, high in metal recovery rate, friendly to the operating environment and the like.

Owner:BEIJING RESEARCH INSTITUTE OF CHEMICAL ENGINEERING AND METALLURGY

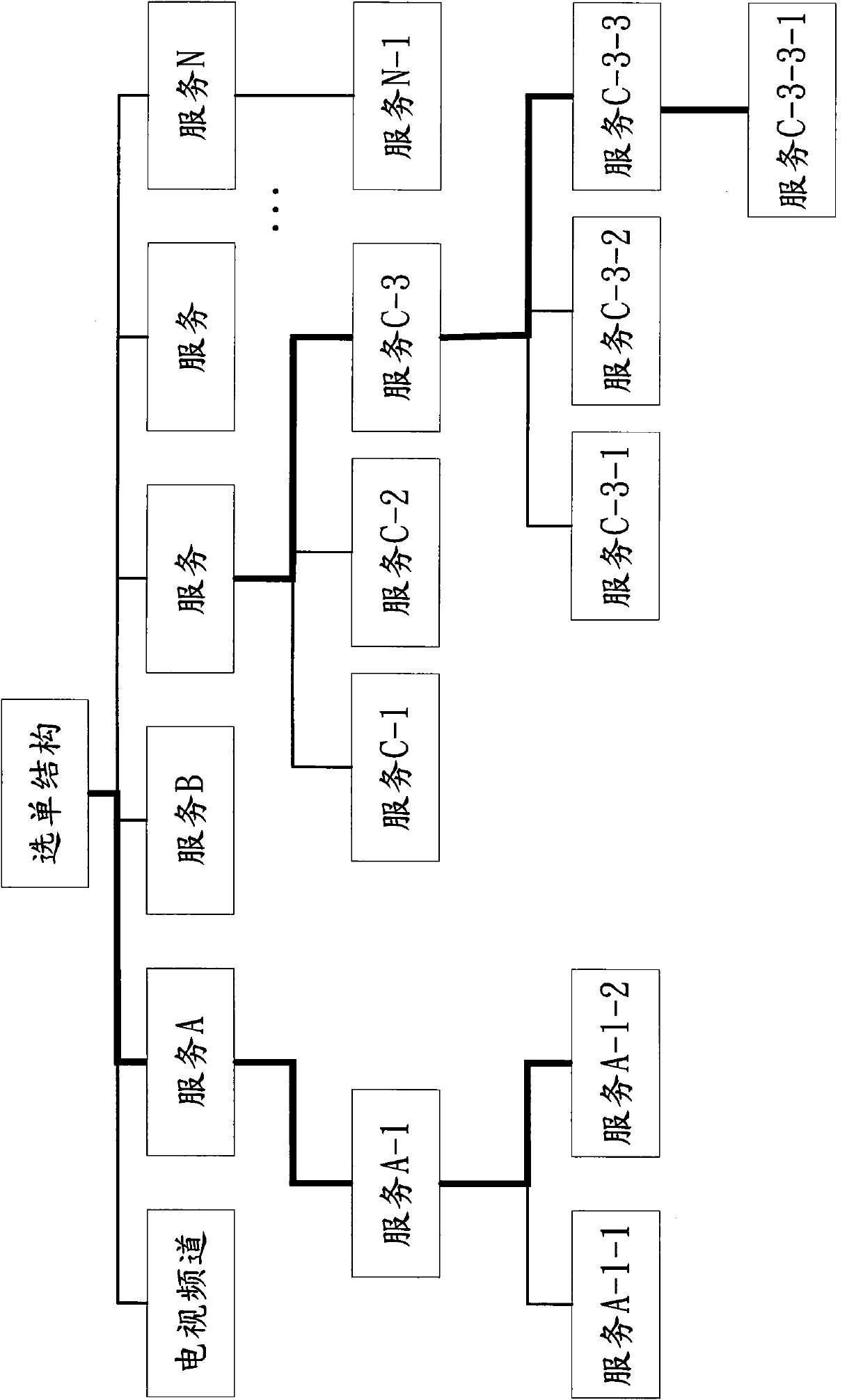

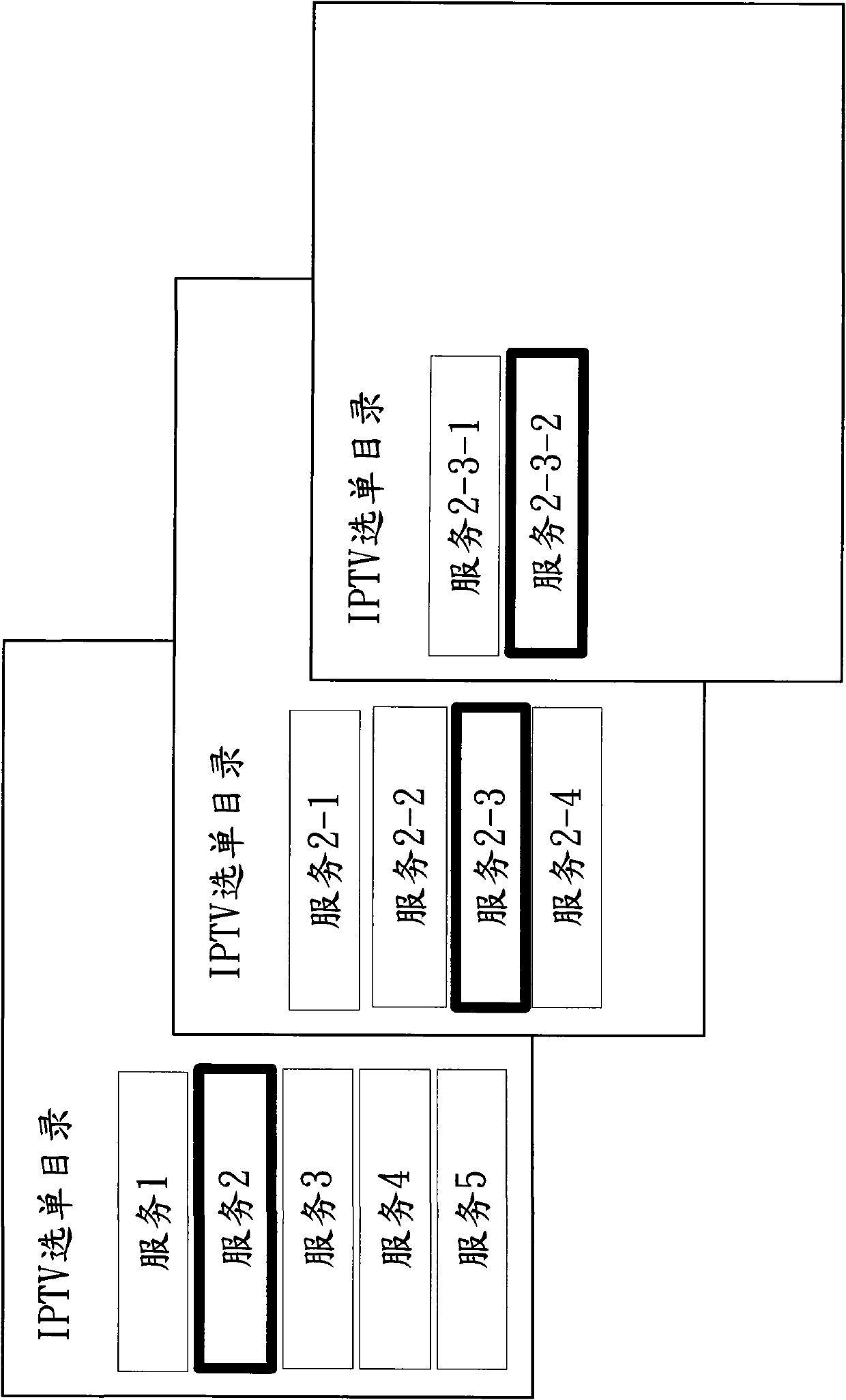

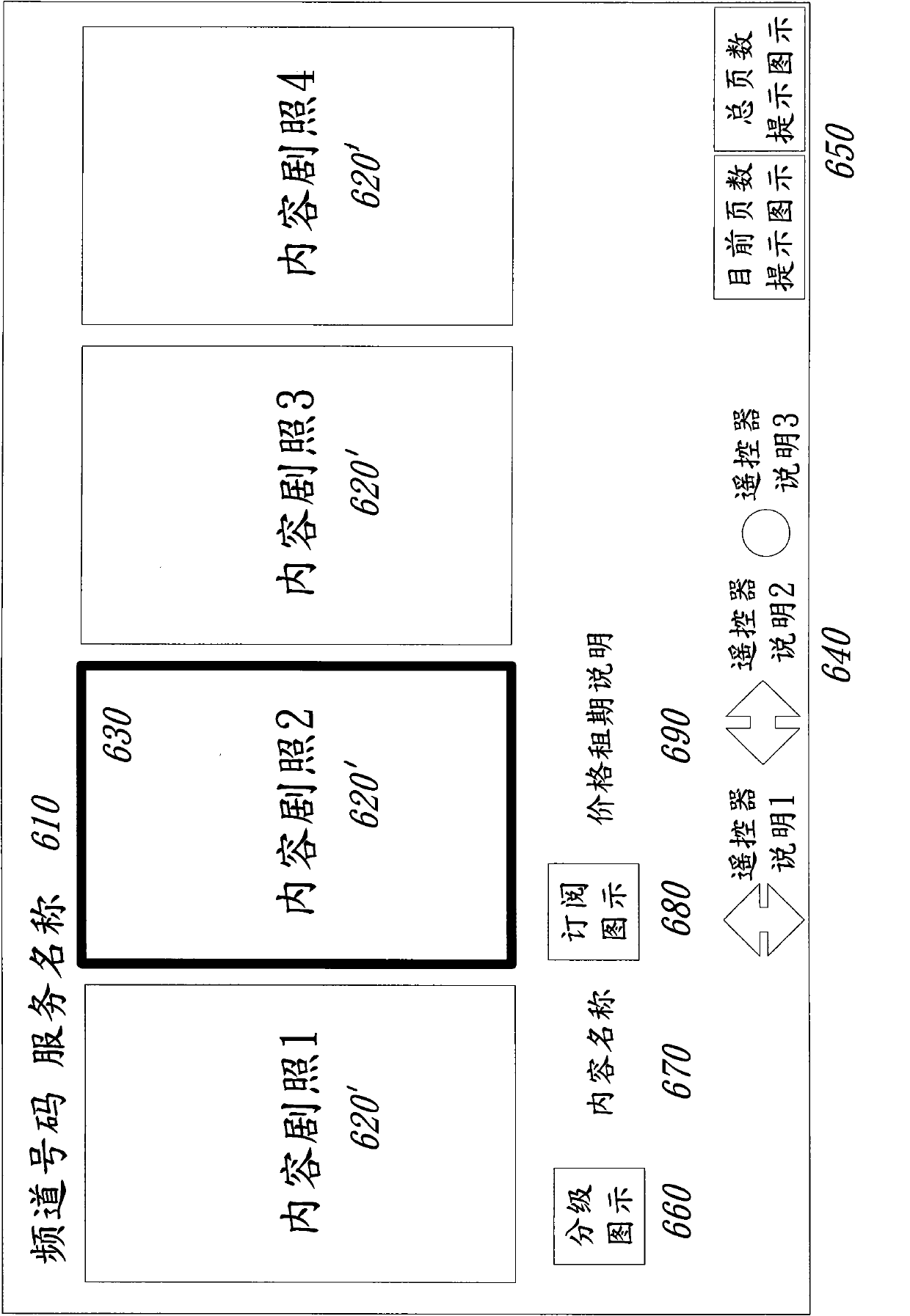

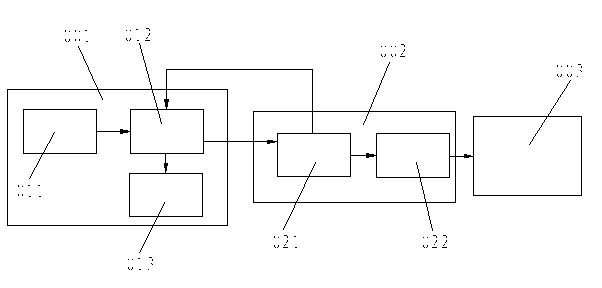

Service design and channel method for network protocol television

ActiveCN101909198APleasant environmentEliminate complicated menu button clicksTelevision system detailsColor television detailsNetworking protocolService design

The invention discloses a service design and channel (hereinafter referred to as service channelization) method for a network protocol television. Conventional services are hidden in layers of text menus and therefore are complex in operation and difficult to find and use. In the method, through the set connection between channels and service attributes, the service content display and service functions are combined a television channel playing function which a user is most familiar to and uses most commonly. The method aims to provide simple and instinctive operation for the user to learn to use services provided by IPTV quickly and for the user to switch the television channels and other non-channel hot services, avoiding menu selection and complex menu selection with frequent inter-channel switching, and providing a pleasant use environment for the user.

Owner:CHUNGHWA TELECOM CO LTD

Resourceful treatment system for high-concentration fumaric acid waste water

InactiveCN103011458ASmall footprintIncrease automation rateWater/sewage treatment by ion-exchangeWater/sewage treatment bu osmosis/dialysisHigh concentrationFiltration

The invention discloses a resourceful treatment system for high-concentration fumaric acid waste water, and relates to the field of sewage treatment. The resourceful treatment system comprises a pre-treatment system, a nano-filtration treatment system and a recycled water reuse system, wherein the pre-treatment system comprises a filtering device, an adsorption device and a recovery system; the filtering device is connected with the adsorption device, and the adsorption device is connected with the recovery system; and the nano-filtration treatment system comprises two levels of nano-filtration systems, the adsorption device is connected with the two levels of the nano-filtration systems sequentially, a second-level nano-filtration system is connected with the recycled water reuse system, and the adsorption device comprises two resin adsorption columns connected in series.

Owner:无锡恩奈迪技术有限公司

A kind of synthetic method of linear high molecular weight polyphenylene sulfide

Owner:CHANGZHOU UNIV

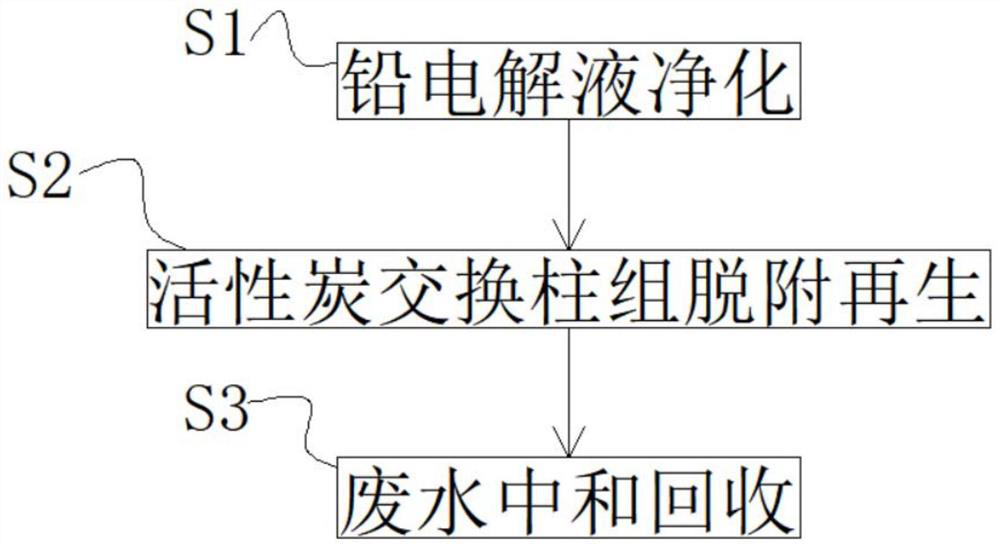

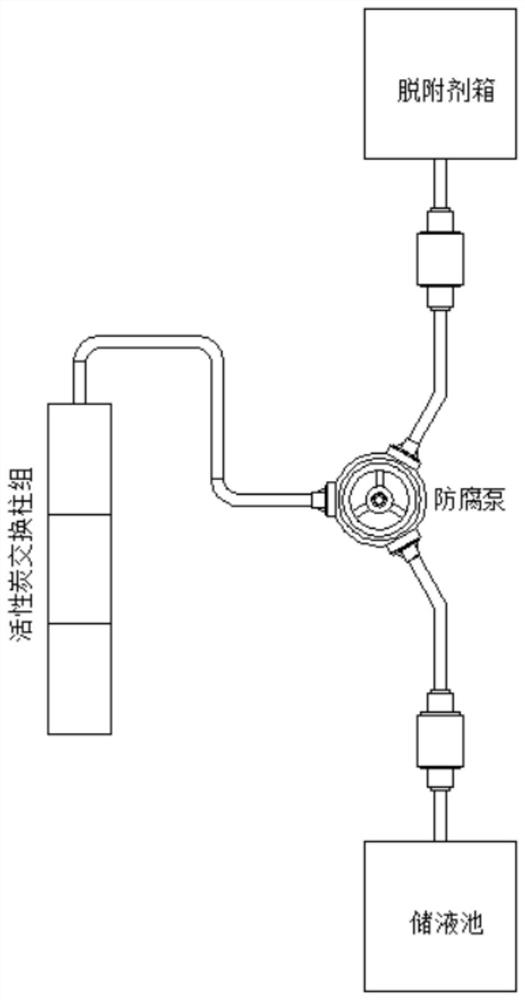

Method for purifying lead electrolyte by using columnar activated carbon

InactiveCN112403028AWill not change the principal componentsFriendly operating environmentIon-exchange process apparatusPhotography auxillary processesActivated carbonElectrolytic agent

The invention discloses a method for purifying a lead electrolyte by using columnar activated carbon, and relates to the technical field of purifying the lead electrolyte by using the activated carbon, in particular to the method for purifying the lead electrolyte by using the columnar activated carbon, which comprises the following steps: S1, purifying the lead electrolyte; S2, performing desorption and regeneration of the activated carbon exchange column group; and S3, neutralizing and recycling the wastewater. According to the method for purifying the lead electrolyte by using the columnaractivated carbon, the activated carbon adsorption exchange column group is adopted for purification, so that the operation is simple, other auxiliary reagents are not needed, and after the activated carbon adsorption exchange column group works for a period of time, desorption regeneration must be carried out generally for three months; substances in the to-be-separated solution can be adsorbed byusing activated carbon; calcium chloride is used as a desorbing agent for desorption and regeneration of the activated carbon; CaCl2 is selected as a desorption agent, so that the adsorption stability of activated carbon to adsorbate can be reduced, and the purpose of reducing desorption activation energy is achieved; and bismuth and antimony ions adsorbed in the activated carbon are eluted through desorption operation, and then the carbon column is washed with purified water to achieve the purpose of activated carbon regeneration.

Owner:郴州雄风环保科技有限公司

Method for measuring content of residual metal elements in OLED (Organic Light Emitting Diode) material

ActiveCN114184445AReduce evaporationReduce lossesPreparing sample for investigationAnalysis by thermal excitationPretreatment methodOrganosolv

The invention discloses a method for measuring the content of residual metal elements in an OLED (Organic Light Emitting Diode) material, and particularly relates to a pretreatment method of extracting a sample by adopting an organic solvent and acidizing and ultrasonically extracting, and a single quadrupole inductively coupled plasma mass spectrometer provided with an organic sampling system is used for detecting. Compared with a conventional dry digestion and acid digestion pretreatment method, the method has the characteristics of rapid pretreatment, less process interference, low detection limit, small background blank, good precision, high accuracy and environmental friendliness in operation.

Owner:SICHUAN AG RAY NEW MATERIALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com