Preparation method for cadmium-containing ceramic glaze standard sample

A technology for standard samples and ceramic glazes is applied in the field of preparation of standard samples of cadmium-containing ceramic glazes, which can solve problems such as unreported preparation methods, and achieve the effects of easy popularization and application, small fluctuation range and accurate quantitative analysis.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

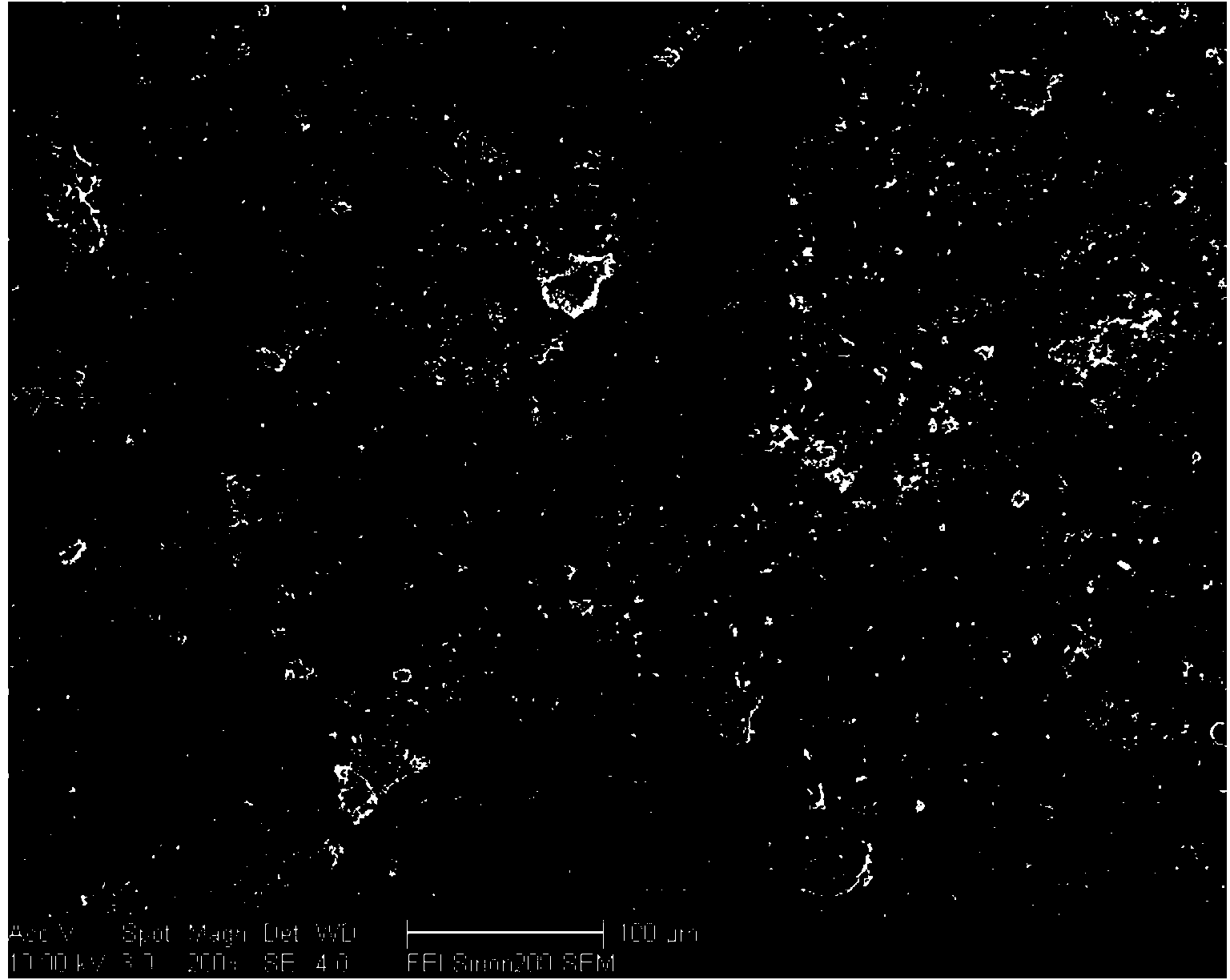

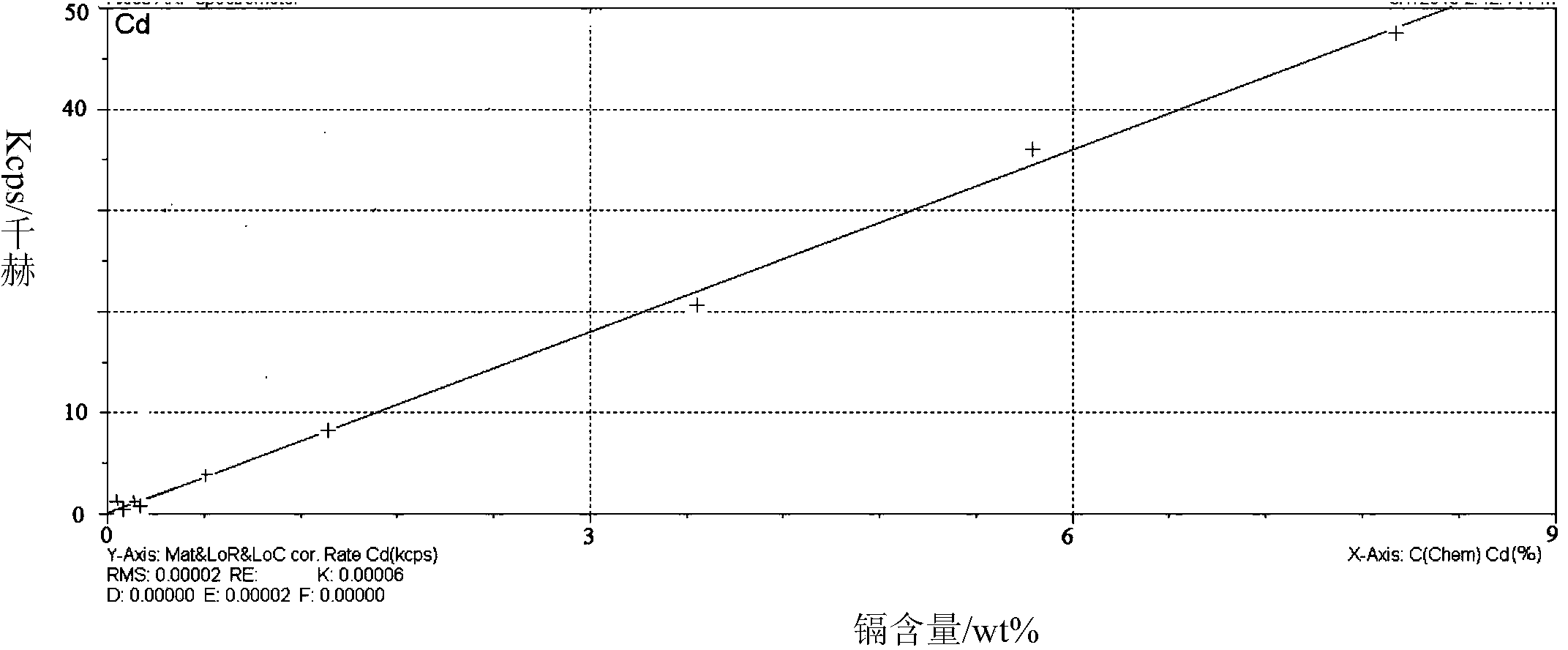

Image

Examples

Embodiment 1

[0040] The preparation of the cadmium-containing ceramic glaze standard sample with a cadmium content of 0.035% and an uncertainty of ±0.003% is as follows:

[0041] (1) Mixing: Weigh 0.01g of cadmium oxide into 24.00g of cadmium-free low-temperature transparent frit glaze, add 6.00g of microcrystalline cellulose and mix evenly to obtain a mixed material;

[0042] (2) Grinding: Wet ball mill the mixed material, balls and water at a mass ratio of 1:15:10 until the particle size is ≤74 μm, and dry in a drying oven at 105°C for 10 hours to obtain dry powder;

[0043] (3) Granulation: Spray 4% of the dry powder mass water into the dried dry powder and distribute evenly to obtain tableting raw materials;

[0044] (4) Molding: Take 10.0g of the tableting raw material and press it on a tableting machine under a pressure of 18MPa to form a disc-shaped sample with a diameter of 32mm and a thickness of 3mm, and dry it in an oven at 110°C for 10h to obtain a tableted sample;

[0045] (5...

Embodiment 2

[0066] The preparation of the cadmium-containing ceramic glaze standard sample with a cadmium content of 0.090% and an uncertainty of ±0.011% is the same as in Example 1, except that:

[0067] Add 0.03g cadmium sulfide as cadmium-containing reagent in step (1);

[0068] In step (5), the temperature is raised to 740° C. and the holding time is 2.5 hours.

[0069] The chemical composition of the transparent frit glaze not containing cadmium element in the present embodiment is: Na 2 O (7.49%), MgO (0.13%), Al 2 o 3 (11.42%), SiO 2 (45.15%), K 2 O(4.79%), CaO(6.68%), Fe 2 o 3 (0.49%), ZrO 2 (1.83%), BaO (4.84%), ZnO (14.47%), SO 3 (2.71%).

Embodiment 3

[0071] The preparation of a cadmium-containing ceramic glaze standard sample with a cadmium content of 0.351% and an uncertainty of ±0.012% is the same as in Example 1, except that:

[0072] In step (1), add 0.14g cadmium chloride as cadmium-containing reagent;

[0073] In step (5), the temperature was raised to 730° C. and then kept for 2 hours.

[0074] The chemical composition of the cadmium-free transparent frit glaze in this embodiment is the same as that in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com