Flotation method for improving grade of flocculent iron ore concentrate

A flocculent iron and concentrate technology, applied in flotation, solid separation, etc., to achieve the effects of low production cost, wide applicability and high recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0026] Another application example of the flotation method for improving the flocculent iron concentrate grade of the present invention comprises the following steps:

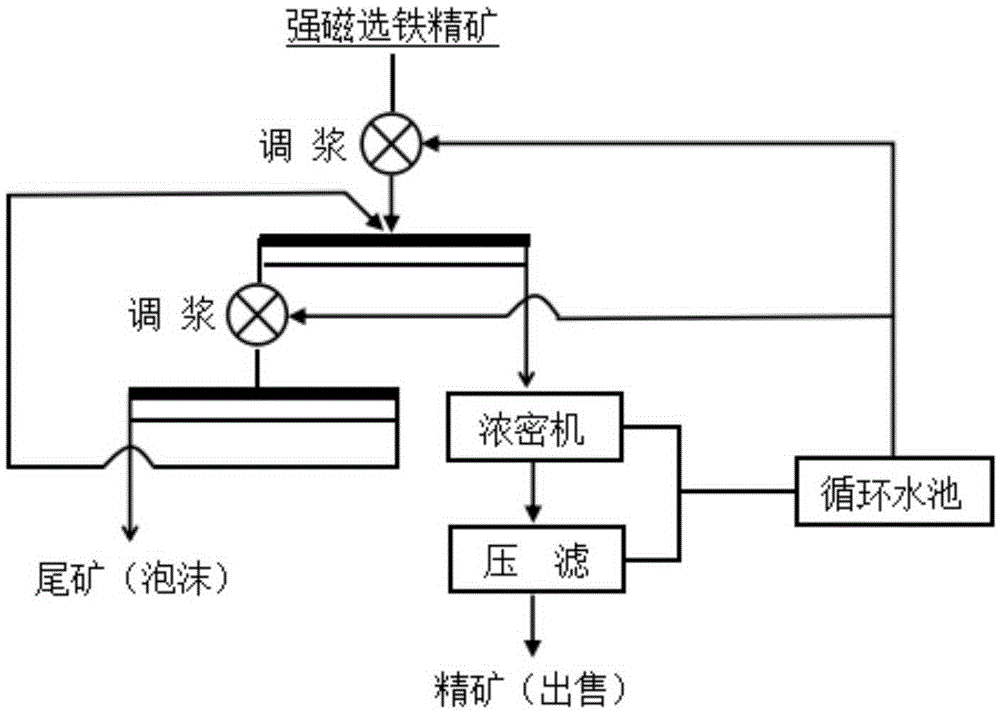

[0027] The red mud is separated by high-gradient magnetic separator to obtain 48-54% iron concentrate with a pH of 8-13. Slurry tank, the slurry is adjusted to a concentration of 30% to 45%, pumped into The vertical stirring mill grinds the ore until the particle size is 44-57μm, and then flows to the The flotation column reverse flotation roughing system, add MH-80 flotation agent at 5~10kg / t dry ore, and the roughing concentrate flows into the Thickener, the underflow is sold after being filtered by a filter press to 15% moisture. Tailings flow into Slurry tank with thick tails, adjust the slurry to 30%~45% concentration, add GH-HL flotation agent at 5~10kg / t dry ore, and after The flotation column selects and sweeps the concentrate to return to the roughing system. After natural dehydration, the t...

Embodiment 3

[0029] Another application example of the flotation method for improving the flocculent iron concentrate grade of the present invention comprises the following steps:

[0030] The red mud is separated by high-gradient magnetic separator to obtain 48-54% iron concentrate with a pH of 8-13. Slurry tank, the slurry is adjusted to a concentration of 30% to 45%, pumped into The vertical stirring mill grinds the ore until the particle size is 57-74μm, and then flows to the The flotation column reverse flotation roughing system, add MH-80 flotation agent at 5~10kg / t dry ore, and the roughing concentrate flows into the Thickener, the underflow is sold after being filtered by a filter press to 15% moisture. Tailings flow into Slurry tank with thick tails, adjust the slurry to 30%~45% concentration, add GH-HL flotation agent at 5~10kg / t dry ore, and after The flotation column selects and sweeps the concentrate to return to the roughing system. After natural dehydration, the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com