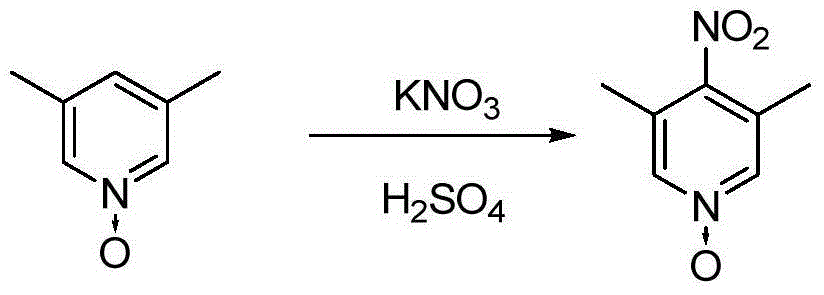

Synthesis method of 3,5-dimethyl-4-nitropyridine-N-oxide

A technology of lutidine and nitropyridine, applied in the field of synthesis of 3,5-dimethyl-4-nitropyridine-N-oxide, which can solve serious problems, equipment corrosion, bad operating environment, etc. , to achieve the effect of short reaction time, high product yield and friendly operation environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Dissolve 12.3g of 3,5-lutidine-N-oxide in 90g of concentrated sulfuric acid, add dropwise a sulfuric acid solution of potassium nitrate (potassium nitrate 14.15g, concentrated sulfuric acid 100g ). After the dropwise addition was completed, the reaction was carried out at a temperature of 60° C. to 65° C. for 2 hours. HPLC monitoring until complete reaction of starting material. Cool down to room temperature, add water and stir, adjust pH to 8-8.5 with ammonia water, filter and dry to obtain 14.4 g of light yellow 3,5-dimethyl-4-nitropyridine-N-oxide, HPLC purity 99%, yield The rate is 85.7%.

Embodiment 2

[0024] Dissolve 12.3g of 3,5-lutidine-N-oxide in 188g of concentrated sulfuric acid, add dropwise a sulfuric acid solution of potassium nitrate (40.44g of potassium nitrate, 600g of concentrated sulfuric acid) at a temperature of 20°C to 30°C ). After the dropwise addition was completed, the reaction was carried out at a temperature of 110° C. to 120° C. for 0.5 hours. HPLC monitoring until complete reaction of starting material. Cool down to room temperature, add water and stir, adjust the pH to 8-8.5 with ammonia water, filter, and dry to obtain 14.5 g of light yellow 3,5-dimethyl-4-nitropyridine-N-oxide, HPLC purity 99%. The yield is 86.3%.

Embodiment 3

[0026] Dissolve 12.3g of 3,5-lutidine-N-oxide in 65g of concentrated sulfuric acid, and dropwise add sulfuric acid solution of potassium nitrate (potassium nitrate 10.11g, concentrated sulfuric acid 60g) at a temperature of 10°C to 15°C ). After the dropwise addition is completed, the reaction is carried out at a temperature of 85° C. to 90° C. for 1 hour. HPLC monitoring until complete reaction of starting material. Cool down to room temperature, add water and stir, adjust pH to 8-8.5 with ammonia water, filter and dry to obtain 14.3 g of light yellow 3,5-dimethyl-4-nitropyridine-N-oxide, HPLC purity 99%, yield rate of 85%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com