Method for preparing super-hydrophobic conductive cellulose fabrics by CNT (carbon nano tube) finishing technology

A cellulose fabric, carbon nanotube technology, applied in fiber processing, plant fibers, textiles and papermaking, etc., can solve the problems of complex process, high energy consumption, unfavorable energy saving and emission reduction, etc., and achieves simple and convenient operation and friendly operating environment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Step 1. Mix 400 mg of multi-walled carbon nanotubes, 50 ml of 5% perfluorosulfonic acid solution by mass percent, 80 ml of water, and 70 ml of absolute ethanol, and use ultrasonic treatment for 2 hours to obtain a carbon nanotube dispersion.

[0023] Step 2. Soak the plain cotton woven fabric in the above-mentioned carbon nanotube dispersion for 5 minutes, and then dry the fabric (with a scraping rate of about 75%) to obtain a treated sample.

[0024] Step 3. Put the treated sample in an oven, and bake at 60° for 5 minutes, and then at 80° for 15 minutes.

[0025] Step 4. When repeating Step 2 and Step 3 three times:

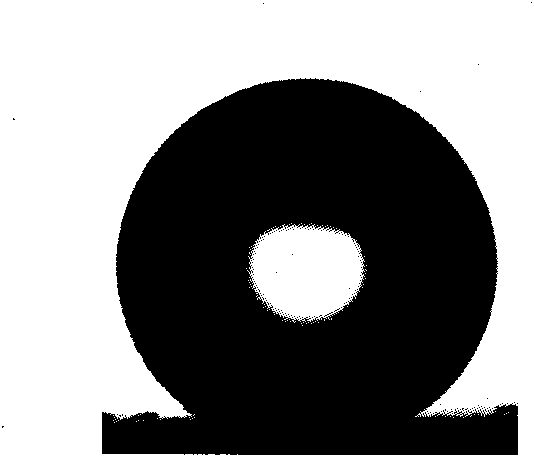

[0026] The surface electron microscope photos of the finished cotton fabrics are as follows: figure 1 As shown, the measured contact angle of the cotton fabric after finishing is 152°,

[0027] Such as figure 2 As shown, the surface resistance is 600Ω-1000Ω / Square.

[0028] When repeating step 2 and step 3 6 times:

[0029] The surface electron micr...

Embodiment 2

[0032] Step 1. Mix 400mg of multi-walled carbon nanotubes, 50ml of perfluorosulfonic acid solution with a concentration of 5% by mass, 120ml of water, and 40ml of absolute ethanol, and use ultrasonic treatment for 2 hours to obtain a carbon nanotube dispersion.

[0033] Step 2. Immerse the plain cotton woven fabric in the carbon nanotube dispersion solution for 5 minutes, and then dry the fabric (with a margin of about 75%) to obtain a treated sample.

[0034] Step 3. Put the treated sample in an oven, and bake at 60° for 5 minutes, and then at 80° for 15 minutes.

[0035] Step 4. When repeating Step 2 and Step 3 three times:

[0036] The measured contact angle of the cotton fabric after finishing is 151°, as Figure 5 As shown, the surface resistance is 600Ω-1000Ω / Square.

[0037] When repeating step 2 and step 3 6 times:

[0038] The measured contact angle of the cotton fabric after finishing is 154°, as Figure 6 As shown, the surface resistance is 200-400Ω / square.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com