Method for separating halogen ions such as chlorine, fluorine and the like from sulfate

A halogen ion and sulfate technology, which is applied in the field of environmental protection and chemical industry, can solve the problems of sulfate crystallization, chlorine and fluorine halogen ion enrichment, poor device reliability, etc., to avoid synergistic corrosion, friendly operating environment, and flexible operation big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

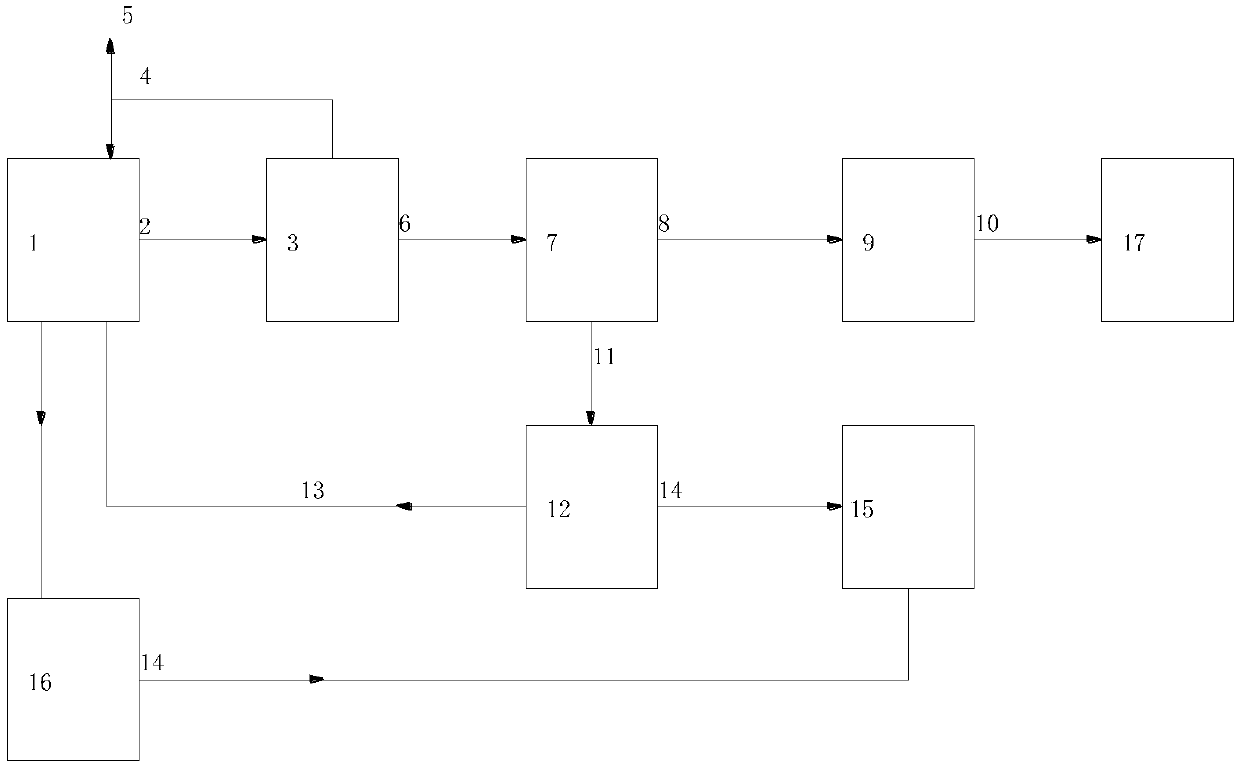

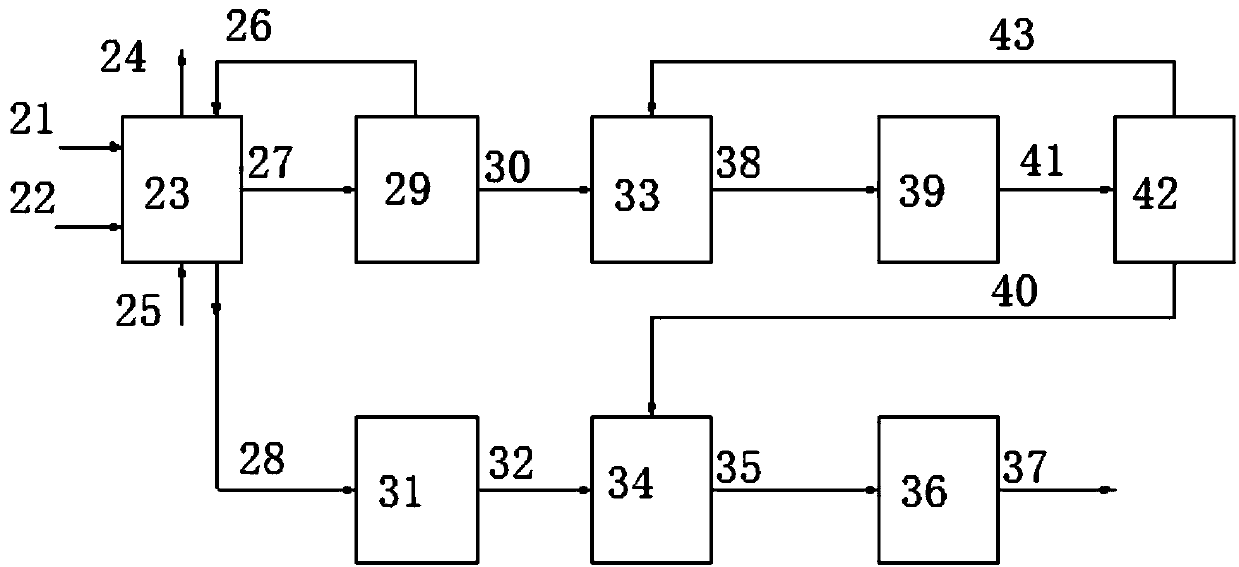

[0041] Ammonium chloride is separated from the ammonium sulfate solution by using nanofiltration separation technology, and the ammonium sulfate mother liquor is returned to the desulfurization system to produce ammonium sulfate according to the normal crystallization method, and the separated ammonium chloride solution is evaporated using the conventional ammonium chloride in the fertilizer and chemical industry+ Crystallization by cooling crystallization process. Separately crystallized ammonium chloride can be dried and packaged together with ammonium sulfate, or can be dried and packaged separately. The specific implementation is as figure 2 As shown, a method for separating halogen ions such as chlorine and fluorine from sulfate includes four main steps: stock solution pretreatment 3, nanofiltration membrane separation 29, nanofiltration retentate, i.e. ammonium sulfate solution disposal 26, nanofiltration permeation Liquid disposal means evaporation or membrane concent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com