Method for preparing lead electrolyte by utilizing industrial waste liquids

A lead electrolyte and industrial waste liquid technology, applied in the chemical industry, can solve the problems of high energy consumption, high production cost, unfavorable environmental protection, etc., and achieve the effects of saving mineral resources, reducing emissions and pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

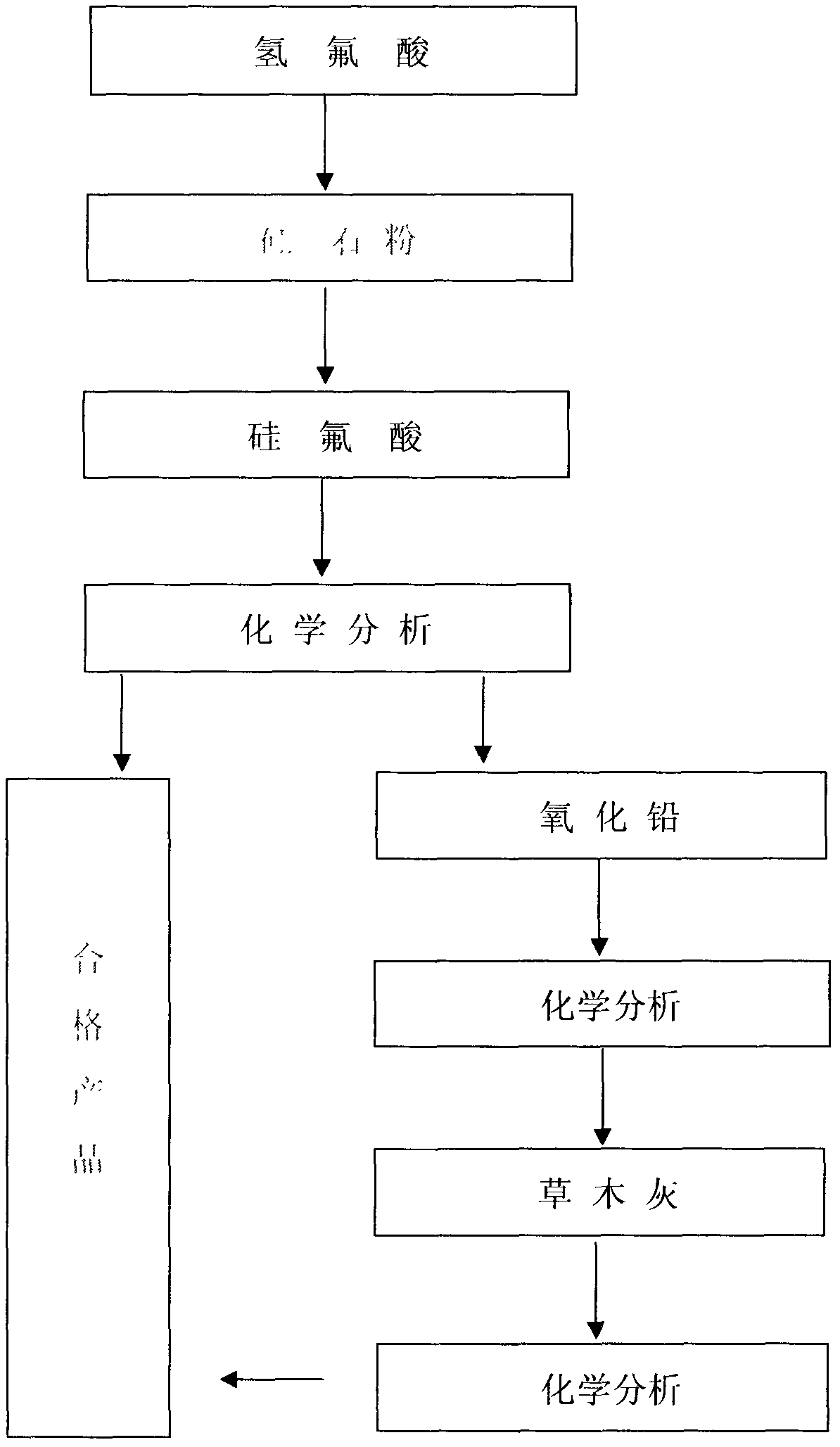

[0007] like figure 1 Shown, the method for utilizing industrial waste liquid to produce lead electrolyte, operates according to the following steps:

[0008] (1) Using the waste liquid produced by industrial production of high-calcium fertilizer, phosphate fertilizer and anhydrous hydrofluoric acid as raw materials. These waste liquids mainly contain hydrofluoric acid, fluorosilicic acid, and elements such as sulfur and phosphorus. The production of lead electrolyte is to use useful components such as hydrofluoric acid and fluorosilicic acid to remove sulfur, phosphorus, copper, iron, etc. at the same time. The process of harmful elements; (2) After the waste liquid raw materials enter the factory, first test the content of various components, and add water to dilute according to the content of hydrofluoric acid and fluorosilicic acid in the above raw materials (to avoid volatilization due to excessive concentration of fluorosilicic acid, and (3) Add silica powder according t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com