Planar connector

一种连接器、平面状的技术,应用在连接、两部件连接装置、耦合装置等方向,能够解决填充压力变高、未得到性能平衡性、流动性不充分等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0064] Hereinafter, the present invention will be specifically described by way of examples, but the present invention is not limited thereto. In addition, measurements and tests of physical properties in Examples were carried out by the following methods.

[0065] (1) Apparent melt viscosity

[0066] The apparent melt viscosity was measured according to ISO11443 at a temperature of 360° C. and a shear rate of 1000 / s using a capillary rheometer with L=20 mm and d=1 mm (CAPILOGRAPH 1B manufactured by Toyo Seiki Co., Ltd.). The measurement was performed at 380°C when liquid crystal polymer 1 and liquid crystal polymer 2 were used, at 350°C when liquid crystal polymer 3 was used, and at 360°C when liquid crystal polymer 4 was used.

[0067] (2) Determination of connector flatness

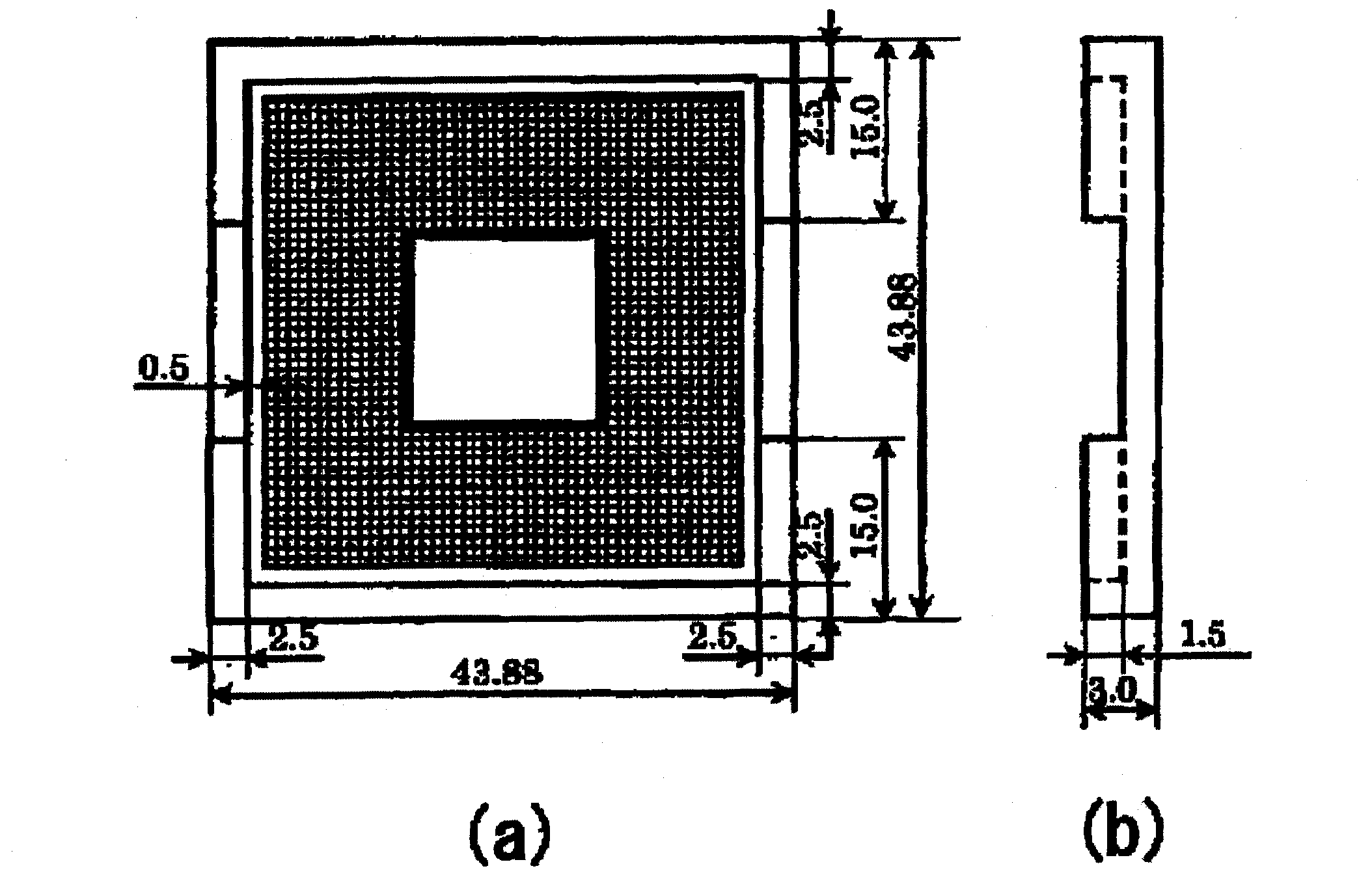

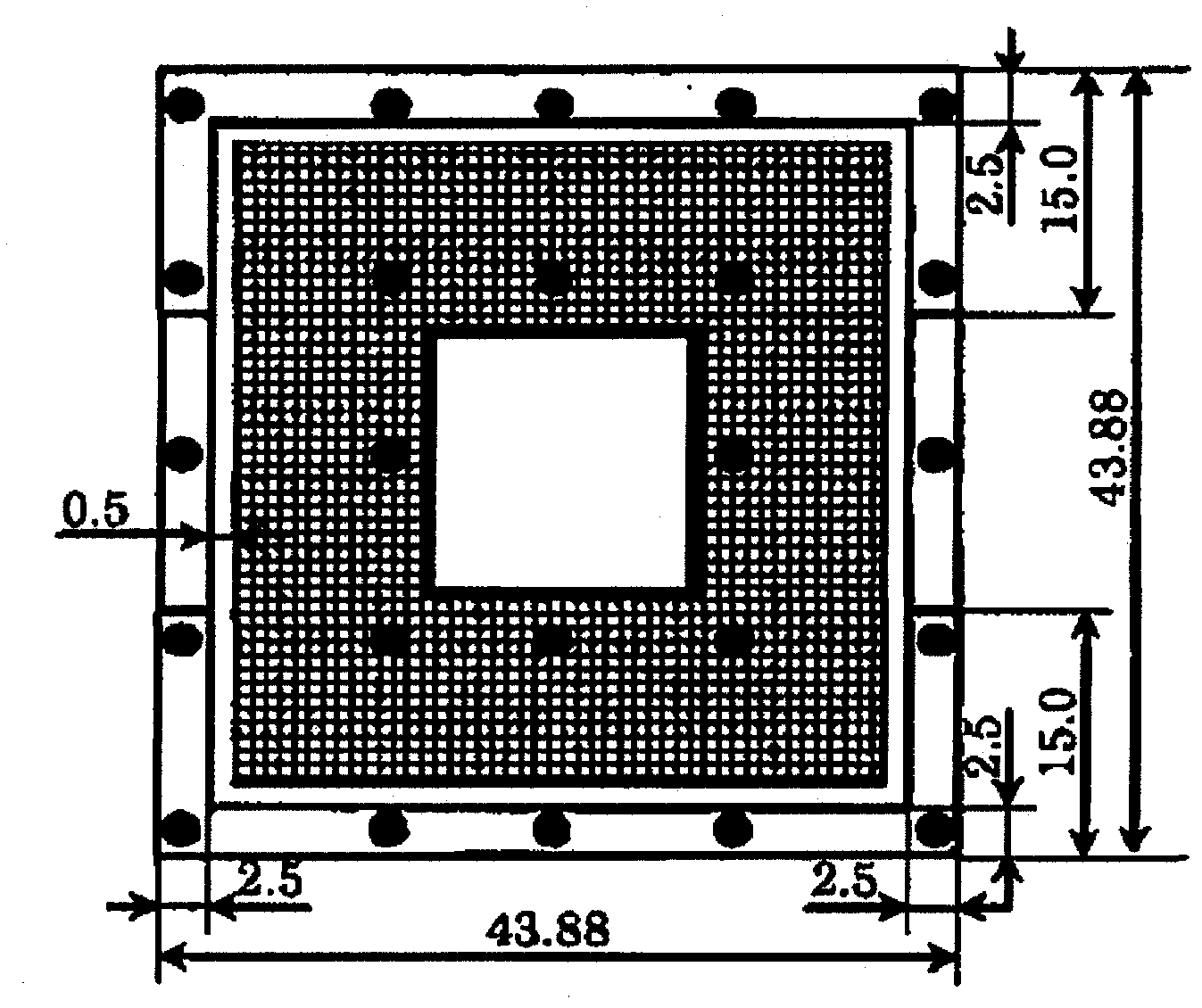

[0068] Injection molding from resin composition pellets under the following molding conditions such as figure 1 The planar connector shown below (the number of pin holes is 1248pin): the overall siz...

Embodiment 7

[0090] Mold temperature: 80°C

[0091] Injection speed: 300mm / sec

[0092] Holding pressure: 50MPa

[0093] Filling time: 0.09~0.11sec

[0094] Holding time: 1sec

[0095] Cooling time: 10sec

[0096] Screw speed: 120rpm

[0097] Screw back pressure: 1MPa

[0098] (3) Melting point of liquid crystal polymer

[0099] Using a differential thermal analysis device (TA Instruments Q-1000), the polymerized polymer was heated from room temperature to 400°C at a temperature increase of 20°C / min and kept for 3 minutes, and then cooled at 20°C / min It was cooled to room temperature under the condition, and then measured again under the condition of heating up at 20°C / min.

[0100] (4) Minimum filling pressure

[0101] injection molding figure 1 The minimum injection filling pressure that can get a good molded product is the minimum filling pressure when the planar connector is used.

[0102] (5) Grid strength

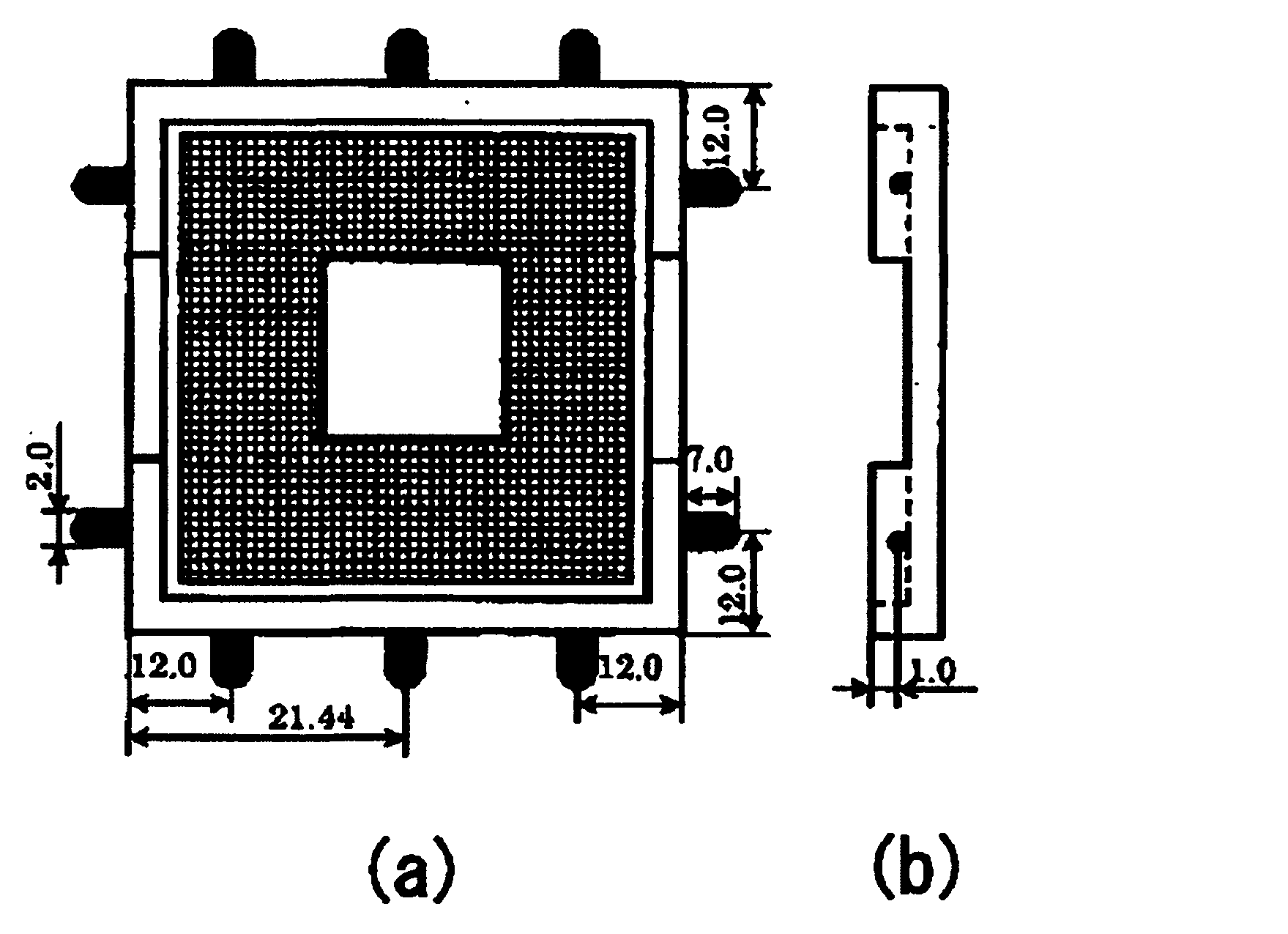

[0103] use figure 1 of planar connectors, determined Figure 4 T...

Embodiment 1~7 and comparative example 1~8

[0126] The above-mentioned test pieces of the liquid crystalline polymer composition containing platy fillers and fibrous fillers were prepared and evaluated under the following conditions, and the results shown in Table 1 were obtained. In addition, in Comparative Example 8, a good test piece could not be obtained by injection molding.

[0127] [manufacturing conditions]

[0128] (use ingredients)

[0129] (A) liquid crystal polymer

[0130] · Liquid crystal polymer 1

[0131] Into a polymerization vessel equipped with a stirrer, a reflux column, a monomer input port, a nitrogen gas introduction port, and a decompression / outflow line, the following raw material monomers, a metal catalyst, and an acylating agent were charged.

[0132] · (I) 1218g (48mol%) 6-hydroxy-2-naphthoic acid (HNA)

[0133] · (II) 560 g (25 mol%) terephthalic acid (TA)

[0134] (III) 628g (25 mol%) 4,4'-dihydroxybiphenyl (BP)

[0135] (IV) 37g (2 mole %) 4-hydroxybenzoic acid (HBA)

[0136] · Pota...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

| logarithmic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com