A kind of phosphorus-free degreasing agent and preparation method thereof

A technology of degreasing agent and fat, which is applied in the field of phosphorus-free degreasing agent and its preparation, can solve problems such as adverse effects of the process, achieve the effects of reducing adverse effects, reducing adsorption, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

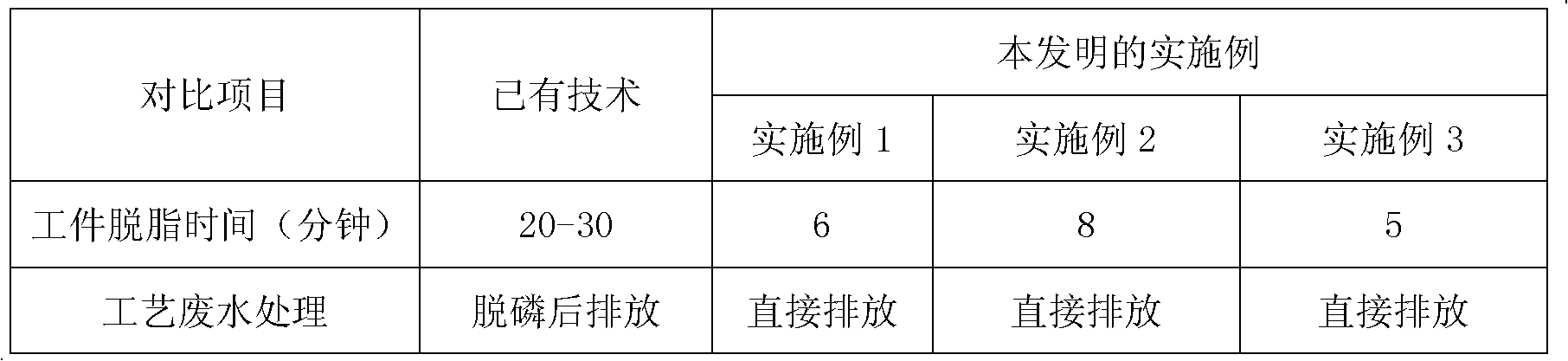

Examples

Embodiment 1

[0035] A kind of phosphorus-free degreasing agent, the mixed solution that is prepared by following components, the weight part of each component in every liter of mixed solution is:

[0036] Sodium Fatty Alcohol Polyoxyethylene Ether Sulfate 3.0g

[0037] Nonylphenol ethoxylate 5.0g

[0038] Fatty alcohol polyoxyalkyl ether 4.5g

[0039] Fatty alcohol polyoxyethylene ether 3.5g

[0040] Sodium Lauryl Sulfate 3.0g

[0041] Isopropanol 2.5g

[0042] Disodium edetate 0.1g

[0043] Alkaline lipase 1.5g

[0044] The remaining ingredients are water.

[0045] The specific operations during preparation are as follows:

[0046] (1) Take a small amount of water, first fully mix isopropanol and water;

[0047] (2) Add active agents such as fatty alcohol polyoxyethylene ether sodium sulfate, nonylphenol polyoxyethylene ether, fatty alcohol polyoxyalkyl ether, fatty alcohol polyoxyethylene ether, sodium lauryl sulfate, etc. Join in the isopropanol aqueous solution of step (1) suc...

Embodiment 2

[0052] A kind of phosphorus-free degreasing agent, the mixed solution that is prepared by following components, the weight part of each component in every liter of mixed solution is:

[0053] Sodium Fatty Alcohol Polyoxyethylene Ether Sulfate 2.0g

[0054] Nonylphenol ethoxylate 4.0g

[0055] Fatty alcohol polyoxyalkyl ether 4.0g

[0056] Fatty alcohol polyoxyethylene ether 3.0g

[0057] Sodium Lauryl Sulfate 2.0g

[0058] Isopropanol 2.0g

[0059] Disodium edetate 0.1g

[0060] Alkaline lipase 1.0g

[0061] The remaining ingredients are water.

[0062] The preparation method is the same as in Example 1.

Embodiment 3

[0064] A kind of phosphorus-free degreasing agent, the mixed solution that is prepared by following components, the weight part of each component in every liter of mixed solution is:

[0065] Sodium Fatty Alcohol Polyoxyethylene Ether Sulfate 4.0g

[0066] Nonylphenol ethoxylate 6.0g

[0067] Fatty alcohol polyoxyalkyl ether 5.0g

[0068] Fatty alcohol polyoxyethylene ether 4.0g

[0069] Sodium Lauryl Sulfate 4.0g

[0070] Isopropanol 3.5g

[0071] Disodium edetate 0.12g

[0072] Alkaline lipase 2.0g

[0073] The remaining ingredients are water.

[0074] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com