Cosolvent assisting degreasing method of light-cured 3D printed aluminum oxide ceramic biscuits

A technology of alumina ceramics and 3D printing, applied in the field of additive manufacturing, can solve problems such as insufficient research, achieve the effects of reducing degreasing time, shortening degreasing time, improving degreasing efficiency and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

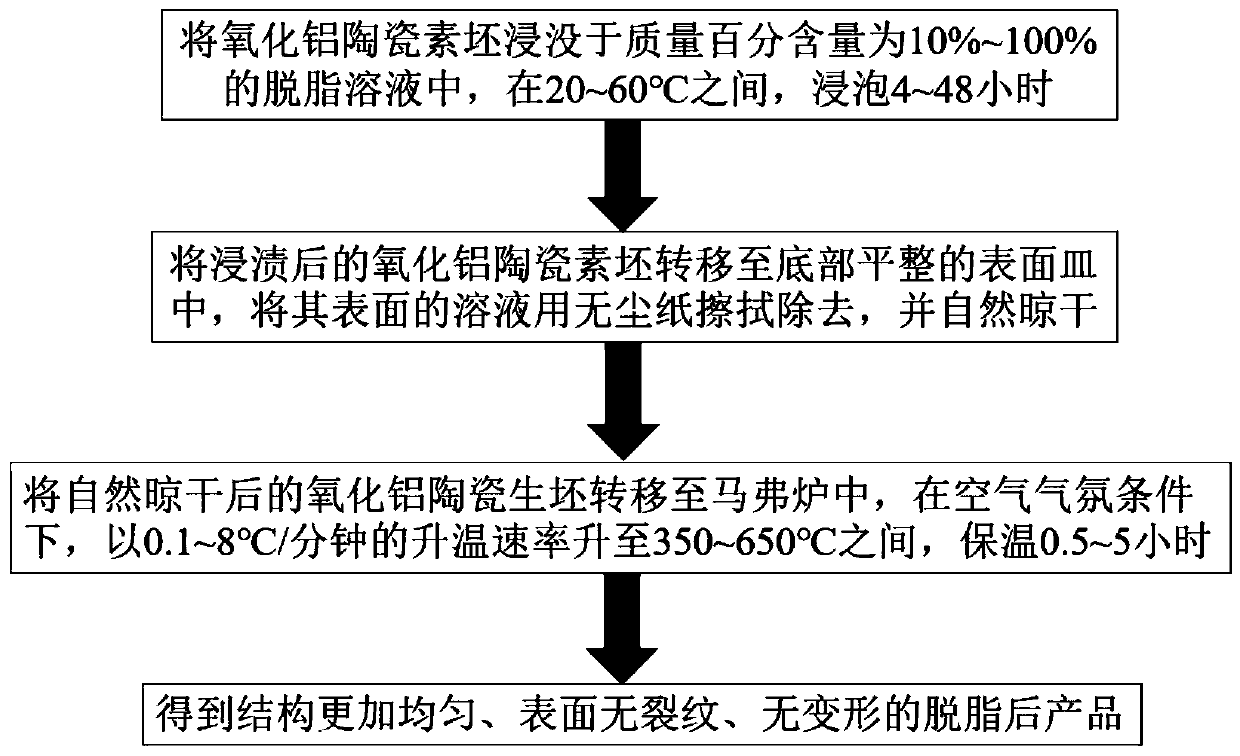

Method used

Image

Examples

Embodiment 1

[0032] Step 1: Submerge the light-cured 3D printed alumina ceramic green body in an ethyl acetate solution with a mass percentage of 40%, and soak for 12 hours at 25°C.

[0033] Step 2: Transfer the impregnated alumina ceramic green body to a watch glass with a flat bottom, wipe off the solution on its surface with a dust-free paper, and let it dry naturally.

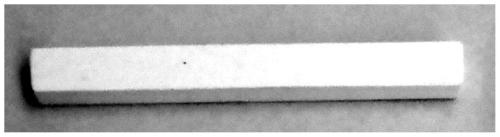

[0034] Step 3: Transfer the naturally dried alumina ceramic green body to a muffle furnace, raise the temperature to 500° C. at a rate of 3° C. / min under air atmosphere, and keep it warm for 2 hours. That is, the cosolvent-assisted degreasing process of the photocured 3D printed alumina biscuit is completed. Samples after degreasing figure 2 shown.

Embodiment 2

[0036] Step 1: Submerge the light-cured 3D printed alumina ceramic green body in an ethyl acetate solution with a mass percent content of 10%, and soak for 12 hours at 20°C.

[0037] Step 2: Transfer the impregnated alumina ceramic green body to a watch glass with a flat bottom, wipe off the solution on its surface with a dust-free paper, and let it dry naturally.

[0038] Step 3: transfer the naturally dried alumina ceramic green body to a muffle furnace, and raise the temperature to between 400° C. at a rate of 5° C. / min under air atmosphere conditions, and keep the temperature for 2 hours. That is, the cosolvent-assisted degreasing process of the photocured 3D printed alumina biscuit is completed. Samples after degreasing figure 2 shown.

Embodiment 3

[0040] Step 1: immerse the light-cured 3D printed alumina ceramic green body in an ethyl acetate solution with a mass percentage of 70%, and soak for 5 hours at 50°C.

[0041] Step 2: Transfer the impregnated alumina ceramic green body to a watch glass with a flat bottom, wipe off the solution on its surface with a dust-free paper, and let it dry naturally.

[0042] Step 3: transfer the naturally dried alumina ceramic green body to a muffle furnace, and raise the temperature to 500° C. at a rate of 8° C. / min under air atmosphere conditions, and keep it warm for 5 hours. That is, the cosolvent-assisted degreasing process of the photocured 3D printed alumina biscuit is completed. Samples after degreasing figure 2 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com