Sanitary ceramic formula and preparation method

A technology of sanitary ceramics and formulations, applied in clay products, applications, household appliances, etc., can solve problems such as high water absorption, hidden dangers, product glaze cracks, etc., to reduce deformation, ensure integrity and tightness, The effect of reducing shrinkage and bulk density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

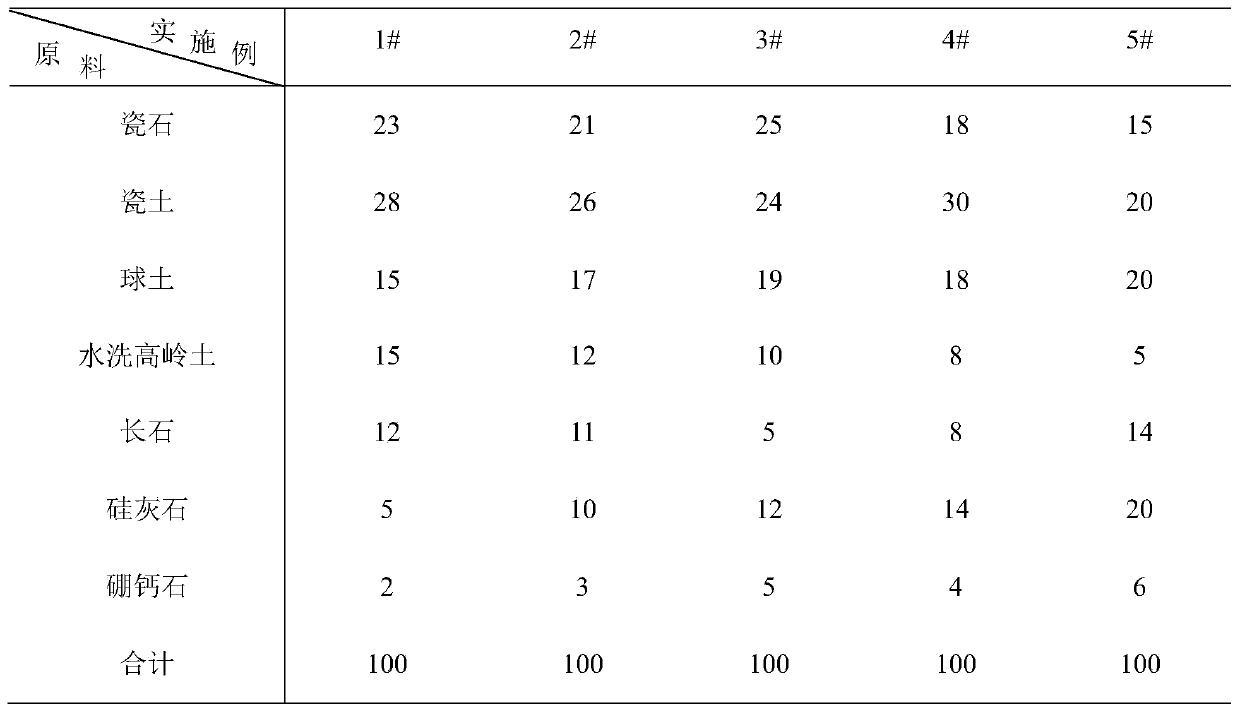

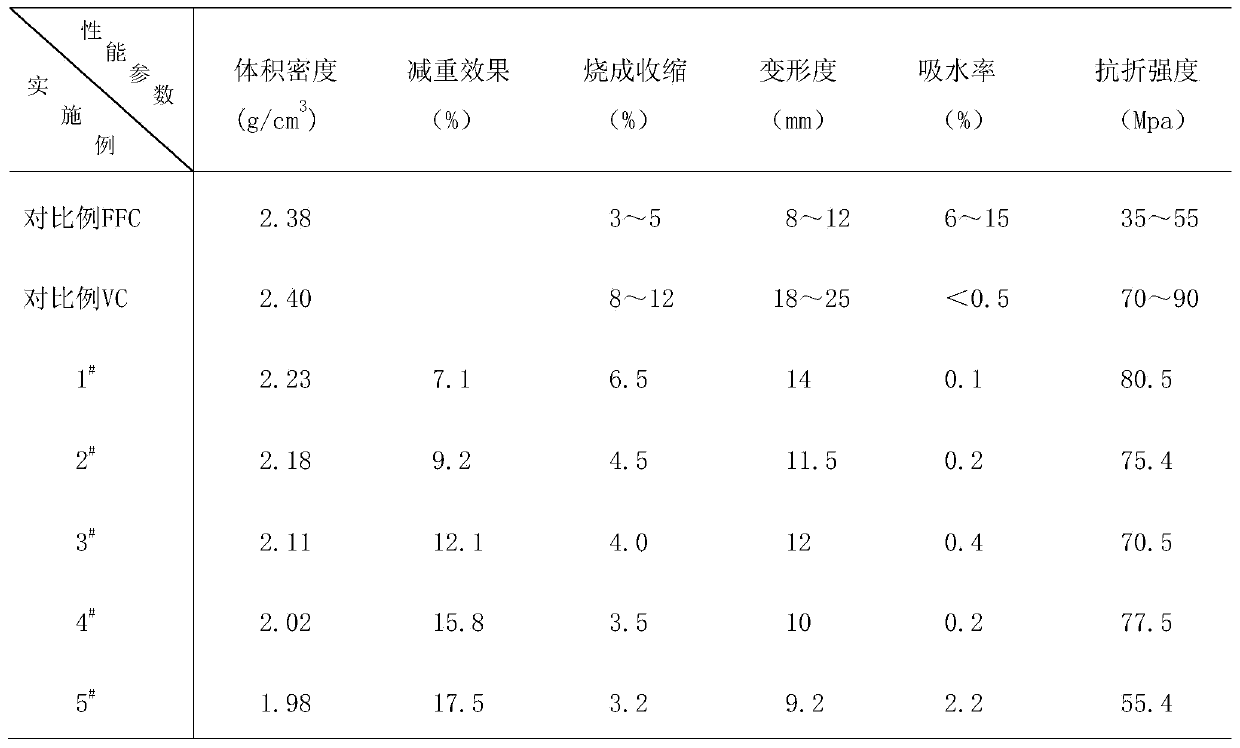

[0026] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

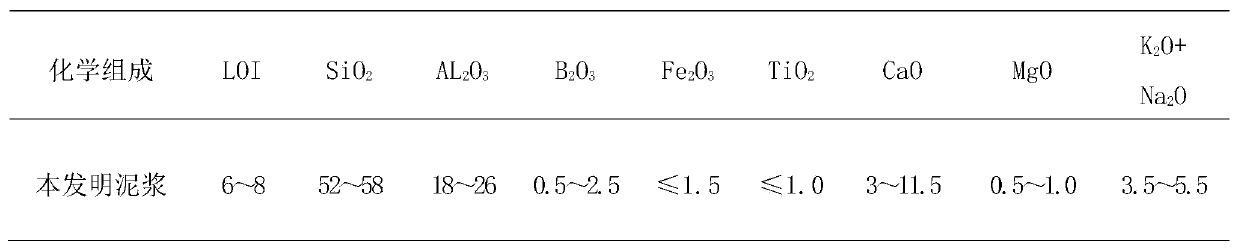

[0027] Such as figure 1 As shown, according to the raw material components in each embodiment, it is put into the mill, and an appropriate debonding agent and water ball mill are added to obtain the mud. Wherein, the raw material boronite is a kind of calcium borate mineral containing water, which is composed of boron Sodium calcite and borax are formed, and the crystals are short columnar. When directly added to the mud, a certain flocculation phenomenon will occur, which will affect its physical performance. In each embodiment, it is pre-fired at 550°C before use to eliminate Its structure contains water, so it can be used directly, so that the mud can be degummed smoothly, which can ensure the improvement of the firin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| fluidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com