Stator disc for a turbomolecular pump

a technology of turbomolecular pump and stator disc, which is applied in the direction of non-positive displacement pumps, liquid fuel engines, mechanical apparatuses, etc., can solve the problems of large deformation force, large deformation degree, and high deformation degree, so as to eliminate the high deformation degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

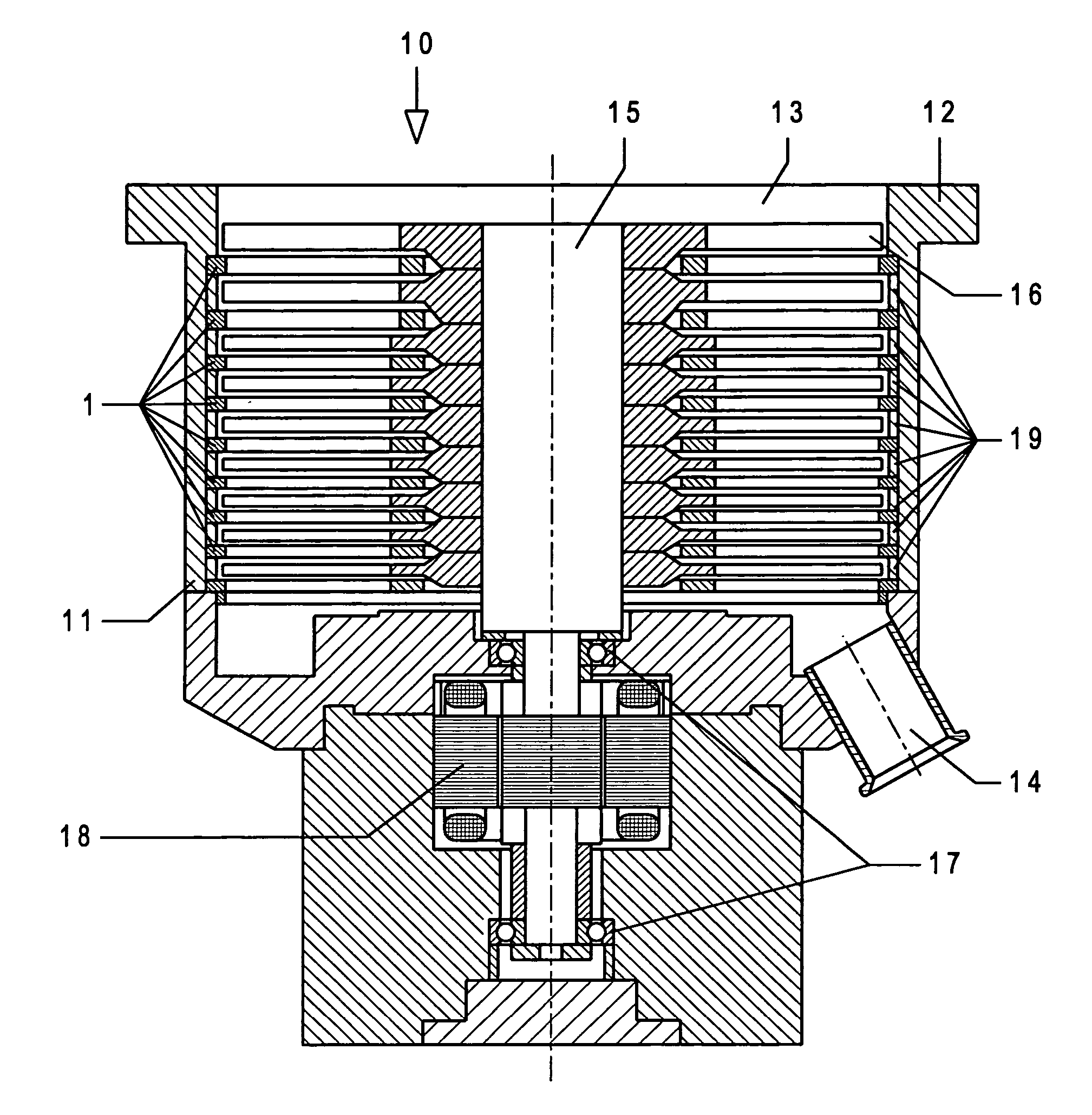

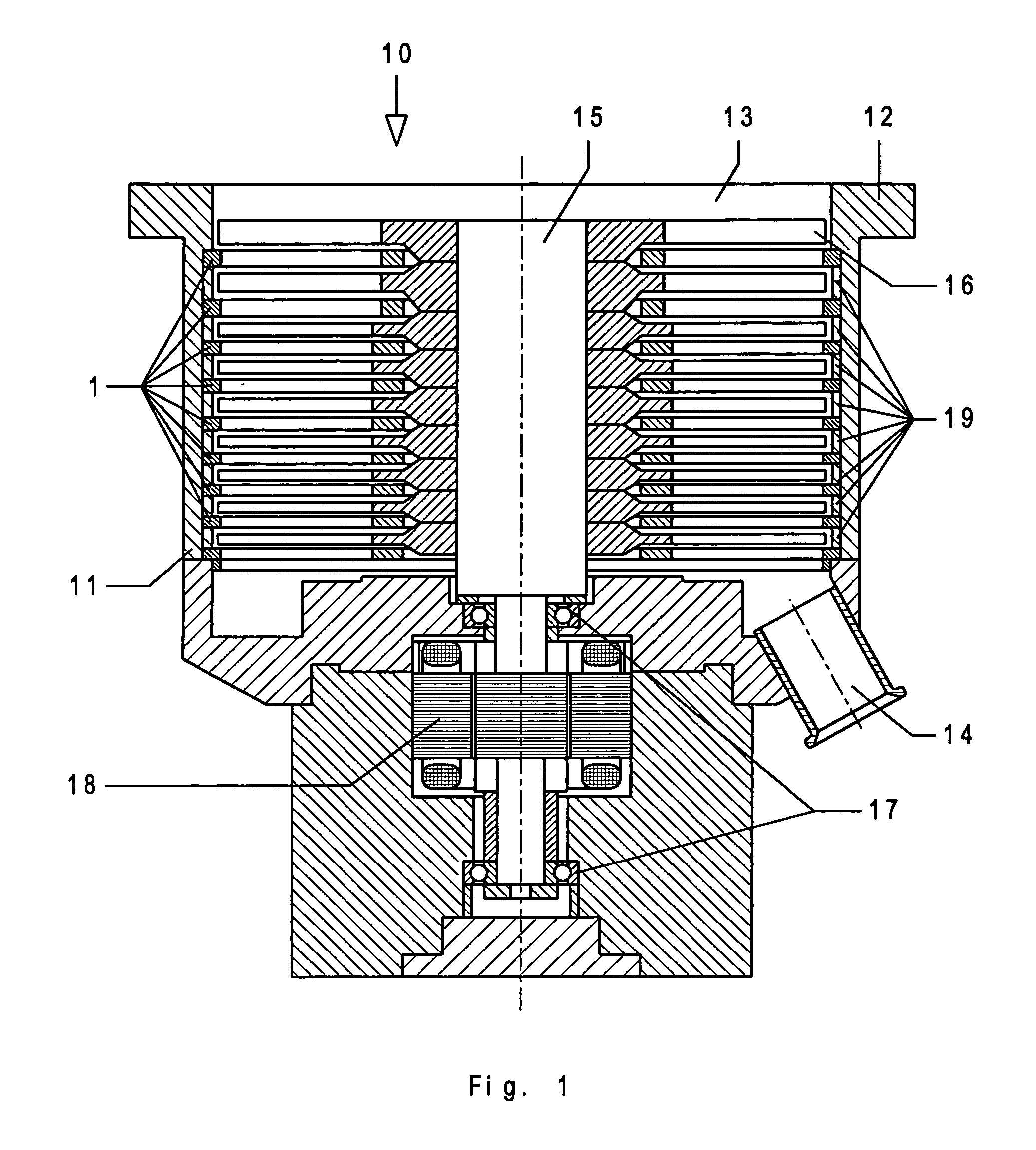

[0022] A turbomolecular pump 10, which is shown in FIG. 1, has a housing 11 with a flange 12 for connecting the pump 10 with a pumped-out recipient. The flange 12 contains a suction region 13. The turbomolecular pump 10 has an outlet 14 from which the compressed gas is expelled. The turbomolecular pump 10 has a rotor shaft 15 which is supported in bearings 17 and is driven, with high speed, by a drive 18. The rotor shaft 15 carries a plurality of discs 16, each carrying vanes. Stator discs 1, which are likewise provided with vanes, are arranged between the rotor discs 16 and are fixedly secured in the housing 11. The stator discs 1 are hold at a distance from each other by spacer rings 19. The pumping action produced by a rapid rotation of the rotor discs 16 and their cooperation with the stator discs 1.

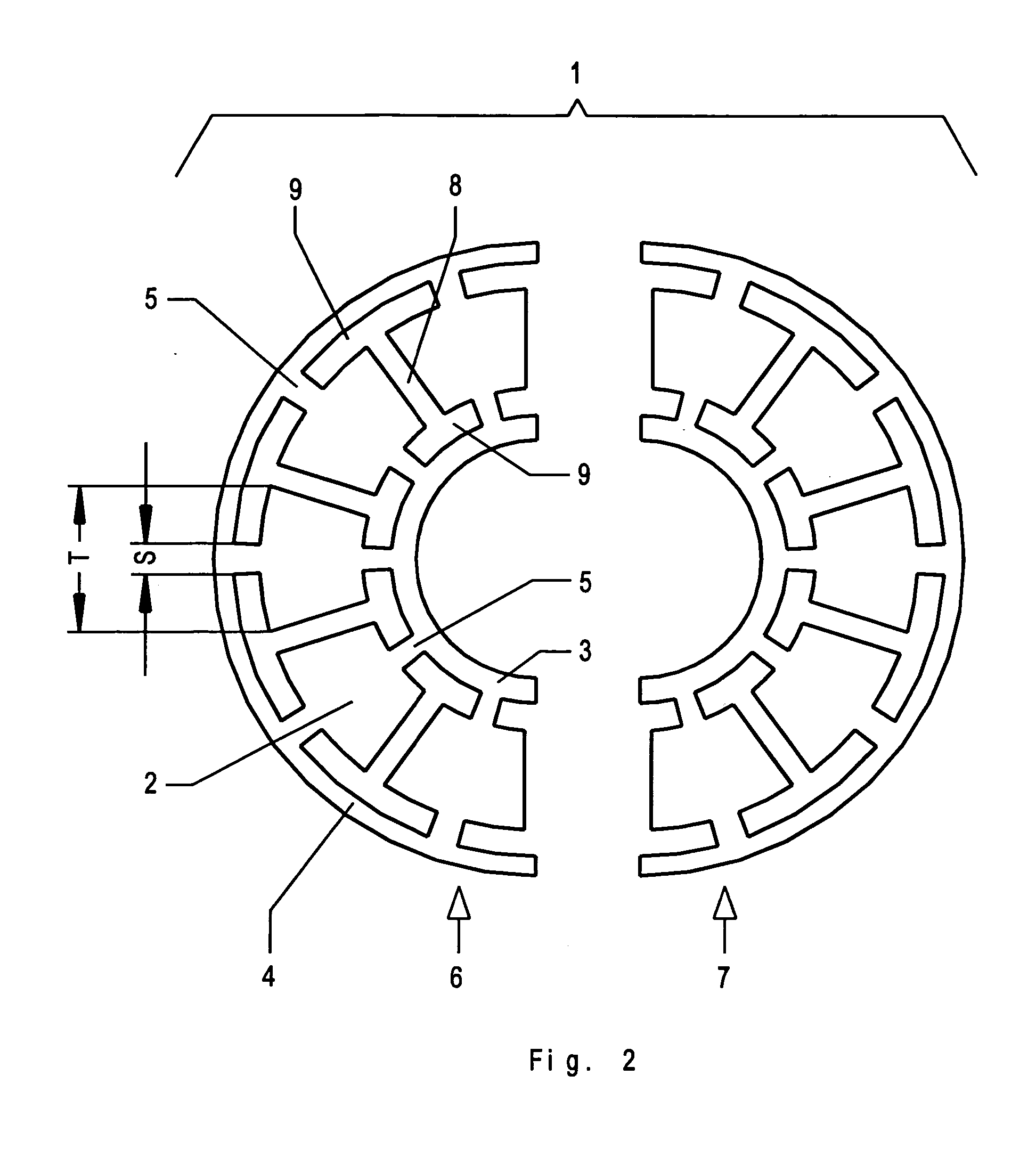

[0023] The stator disc 1 according to the present invention, which is used in the turbomolecular pump 10 and a plan view of which is shown in FIG. 2, is formed of two half-discs 6 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com