Quenching process of high-carbon chromium bearing

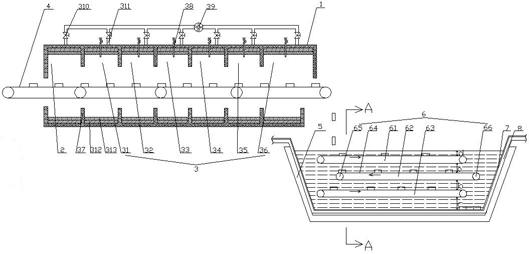

A high-carbon chromium bearing and process technology, used in quenching devices, manufacturing tools, furnace types, etc., can solve the problems of large quenching deformation, large temperature difference between upper and lower oil, surface deformation, etc., to avoid direct impact, improve uniformity, Achieving the effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] A quenching process for high-carbon chromium bearings, the specific steps comprising:

[0058] S1, positioning quenching furnace device;

[0059] S2. Preheating of high-carbon chromium bearings: Place the high-carbon chromium bearings on the conveying platform 4 at equal intervals. The high-carbon chromium bearings move to the preheating chamber 2 along with the conveying platform 4. The preheating temperature is 730°C, and the preheating time is 5min;

[0060] S3. Heating of high-carbon chromium bearings: Nitrogen, methanol and propane are poured into the penetrating agent dropper 38 of each heating chamber. The temperature of the first heating chamber 31 is 770°C, the temperature of the second heating chamber 32 is 775°C, and the temperature of the second heating chamber 32 is 775°C. The temperature of the third heating chamber 33 is 780°C, the temperature of the fourth heating chamber 34 is 785°C, the temperature of the fifth heating chamber 35 is 790°C, the tempera...

Embodiment 2

[0064] A quenching process for high-carbon chromium bearings, the specific steps comprising:

[0065] S1, positioning quenching furnace device;

[0066] S2. Preheating of high-carbon chromium bearings: Place the high-carbon chromium bearings on the conveying platform 4 at equal intervals. The high-carbon chromium bearings move to the preheating chamber 2 along with the conveying platform 4. The preheating temperature is 740°C and the preheating time is 6 minutes;

[0067] S3. Heating of high-carbon chromium bearings: Nitrogen, methanol and propane are poured into the penetrating agent dropper 38 of each heating chamber. The temperature of the first heating chamber 31 is 790°C, the temperature of the second heating chamber 32 is 795°C, and the temperature of the second heating chamber 32 is 795°C. The temperature of the third heating chamber 33 is 800°C, the temperature of the fourth heating chamber 34 is 805°C, the temperature of the fifth heating chamber 35 is 810°C, the tem...

Embodiment 3

[0071] A quenching process for high-carbon chromium bearings, the specific steps comprising:

[0072] S1, positioning quenching furnace device;

[0073] S2. Preheating of high-carbon chromium bearings: Place the high-carbon chromium bearings on the conveying platform 4 at equal intervals. The high-carbon chromium bearings move to the preheating chamber 2 along with the conveying platform 4. The preheating temperature is 750°C and the preheating time is 8 minutes;

[0074] S3. Heating of high-carbon chromium bearings: Nitrogen, methanol and propane are poured into the penetrating agent dropper 38 of each heating chamber. The temperature of the first heating chamber 31 is 810°C, the temperature of the second heating chamber 32 is 815°C, and the temperature of the second heating chamber 32 is 815°C. The temperature of the third heating chamber 33 is 820°C, the temperature of the fourth heating chamber 34 is 825°C, the temperature of the fifth heating chamber 35 is 830°C, the tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com