Method for conducting flexibly-selective rough polishing on surface of polished tile and polished tile rough polishing machine

A polishing brick and selective technology, which is applied in the direction of surface polishing machine tools, grinding/polishing equipment, grinding racks, etc., can solve problems such as hob damage, poor flatness, and corner drop, and reduce deformation , Avoid damage, damage reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The method that the present invention sets forth carries out rough throwing to polishing brick is:

[0015] The grinding head is driven by the motor to rotate at high speed. There are multiple grinding heads, which can move up and down. The operation of each grinding head is independent of each other. The grinding heads are arranged in a straight line horizontally. Width of polished tiles: After the polished tiles on the conveyor belt enter the space under the grinding head, the grinding head can be flexibly selected according to the surface conditions of the polished tiles to roughly polish the surface of the polished tiles.

[0016] The rough throwing machine that the present invention is set forth is set forth below:

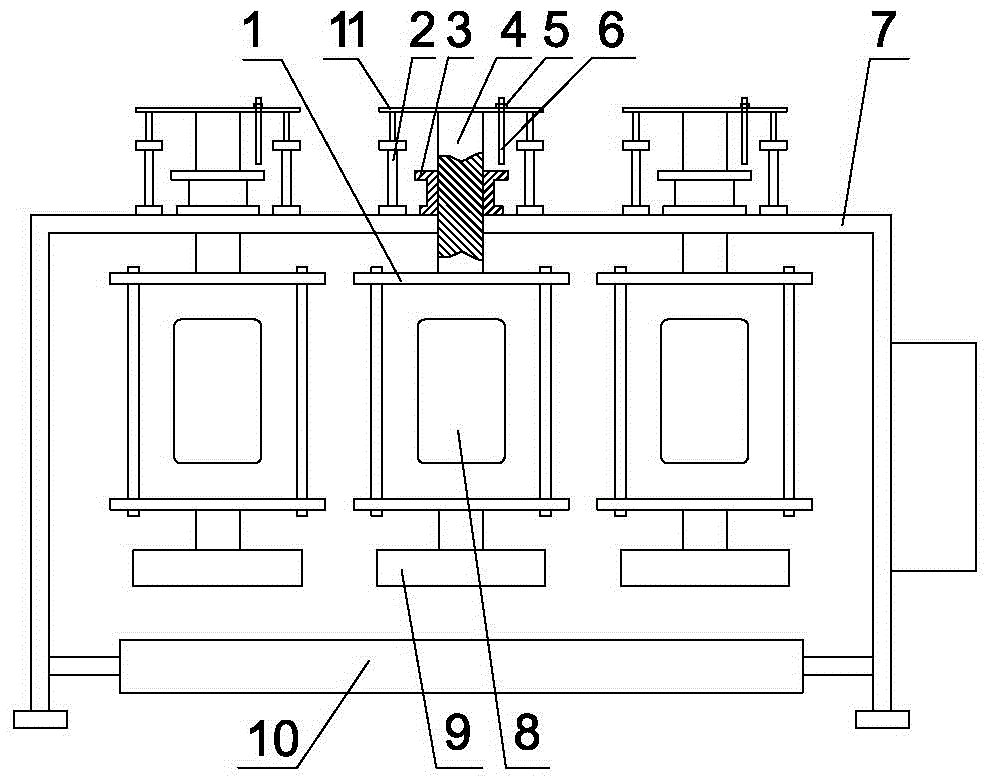

[0017] Such as figure 1 As shown, the number of motors 8 is more than two, and each motor 8 is installed on an independent support 1, and each independent support 1 is connected to a sliding shaft 4, and the top of each sliding shaft 4 is fixed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com