Carbon fiber sheet

A carbon fiber sheet and carbon fiber technology, applied in electronic equipment, lamination, application, etc., can solve problems such as deformation, expansion or shrinkage inconsistency, and achieve the effects of good strength, consistent expansion coefficient, and weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

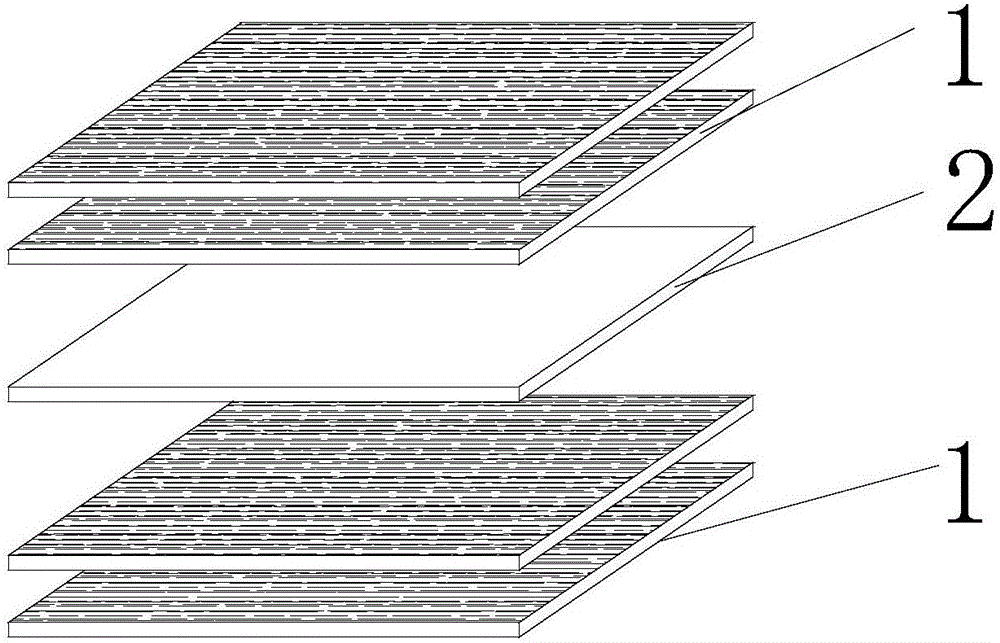

[0029] Such as figure 1 , a carbon fiber sheet proposed by the present invention, including four layers of carbon fiber prepreg and a layer of glass bead-filled epoxy sheet laminate, the glass bead-filled epoxy sheet laminate is arranged on several carbon fiber prepreg In the middle layer position of the material, a layer of carbon fiber woven cloth prepreg is added between carbon fiber prepreg and carbon fiber prepreg, carbon fiber prepreg and glass bead-filled epoxy sheet laminate, and the carbon fiber prepreg composition includes resin And carbon fiber, the resin is epoxy resin, and the carbon fiber is polyacrylonitrile-based carbon fiber.

[0030] Wherein, filler glass floating beads are added in the resin, and the density of the glass floating beads is 0.3 g / cubic centimeter.

[0031] A preparation method of carbon fiber sheet, is characterized in that, comprises the following concrete steps:

[0032] S1: Resin pretreatment: Add filler glass floating beads to the resin ...

Embodiment 2

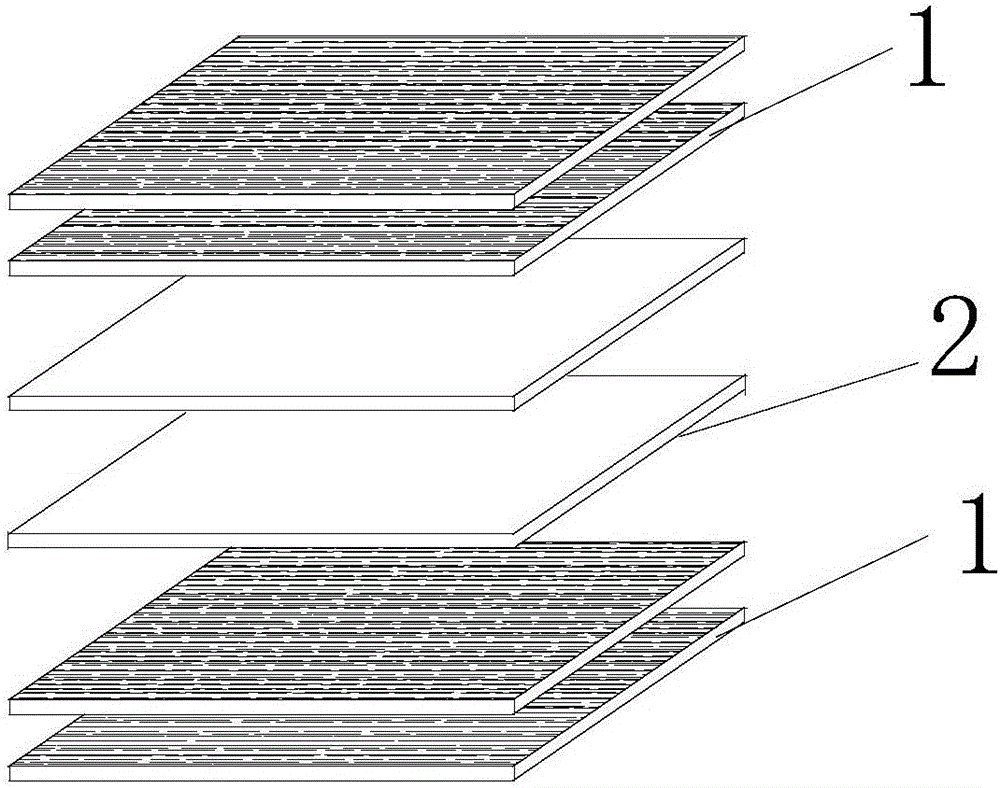

[0041] Such as figure 2 , a carbon fiber sheet proposed by the present invention, including four layers of carbon fiber prepreg and two layers of epoxy sheet laminates filled with glass beads, the epoxy sheet laminates filled with glass beads are arranged on several carbon fiber prepregs In the middle layer position of the material, a layer of carbon fiber woven cloth prepreg is added between carbon fiber prepreg and carbon fiber prepreg, carbon fiber prepreg and glass bead-filled epoxy sheet laminate, and the carbon fiber prepreg composition includes resin And carbon fiber, the resin is epoxy resin, carbon fiber polyacrylonitrile-based carbon fiber.

[0042] Wherein, filler glass floating beads are added in the resin, and the density of the glass floating beads is 0.35 g / cubic centimeter.

[0043] A preparation method of carbon fiber sheet, is characterized in that, comprises the following concrete steps:

[0044] S1: Resin pretreatment: Add filler glass floating beads to ...

Embodiment 3

[0053] Such as figure 1 , a carbon fiber sheet proposed by the present invention, including four layers of carbon fiber prepreg and a layer of glass bead-filled epoxy sheet laminate, the glass bead-filled epoxy sheet laminate is arranged on several carbon fiber prepreg In the middle layer position of the material, a layer of carbon fiber woven cloth prepreg is added between carbon fiber prepreg and carbon fiber prepreg, carbon fiber prepreg and glass bead-filled epoxy sheet laminate, and the carbon fiber prepreg composition includes resin And carbon fiber, the resin is epoxy resin, carbon fiber polyacrylonitrile-based carbon fiber.

[0054] Wherein, filler glass floating beads are added in the resin, and the density of the glass floating beads is 0.4 g / cubic centimeter.

[0055] A preparation method of carbon fiber sheet, is characterized in that, comprises the following concrete steps:

[0056] S1: Resin pretreatment: Add filler glass floating beads to the resin to reduce t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com