High flame retardant low warpage carbon fiber sheet and its preparation process

A carbon fiber sheet, low warpage technology, applied in the field of composite materials, can solve the problems of material performance degradation, large amount of addition, difficult processing, etc., and achieve the effects of offsetting inconsistent shrinkage, reducing weight, and avoiding warping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Toho M40-12 carbon fiber filaments and epoxy resin WP-2200 are made into a unidirectional carbon fiber prepreg with a filament weight of 150g and a resin content of 35%.

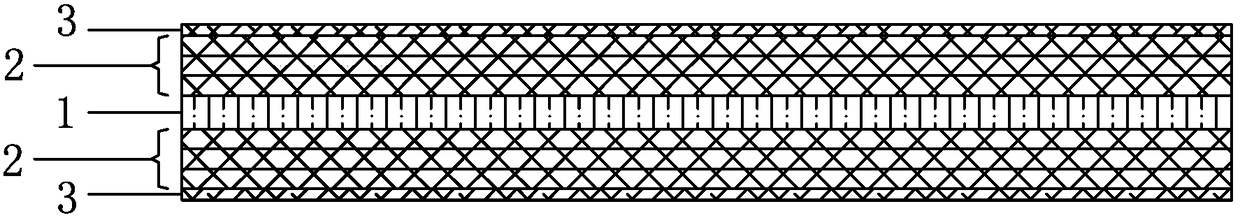

[0037] Laminate six layers of 150g, 35% resin content unidirectional carbon fiber prepreg, and a layer of polycarbonate horn mesh (with plasma surface treatment) for lamination. The lamination is as follows:

[0038] 0°(UD150)+90°(UD150)+0°(UD150)+PC speaker mesh+0°(UD150)+90°(UD150)+0°(UD150),

[0039] Add a layer of PET release film and two layers of kraft paper on both sides of the laminated product, put it into the template, put it into the carrier plate, pressurize it in the flat hot press, heat and cure it, the specific steps are: flat plate The hot press is preheated to 80°C first, and the material is sent into the flat hot press, the mold is closed, vacuumized, heated to 170°C, kept at this temperature for 10 minutes, then cooled to 80°C, restored to normal pressure, and taken out Place the t...

Embodiment 2

[0041] Toho M40-12 carbon fiber filaments and epoxy resin WP-2200 are made into a UD unidirectional prepreg with a filament weight of 100g and a resin content of 35%.

[0042] Toho T300B-3K carbon fiber yarn is woven into 3K plain weave cloth with a weaving machine, the weight is 200g, and then it is made into a silk weight of 200g with epoxy resin WP-2200 (adding 20% glass floating beads), and the resin 30% 3K cloth prepreg.

[0043] Laminate two layers of 200g 3K cloth prepreg with a resin content of 30%, six layers of 100g unidirectional carbon fiber prepreg with a resin content of 35%, and one layer of polycarbonate horn mesh (with plasma surface treatment). Layers are:

[0044] 3K+0°(UD150)+90°(UD150)+0°(UD150)+PC speaker network+0°(UD150)+90°(UD150)+0°(UD150)+3K,

[0045]Add a layer of PET release film and 2 layers of kraft paper on both sides of the laminated product, put it into the template, put it into the carrier plate, pressurize it in a flat hot press, heat an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com