A linear gear mechanism with elastic variable transmission ratio

A technology of variable transmission ratio and wire gear, which is applied in belts/chains/gears, mechanical equipment, components with teeth, etc., can solve the problems that transmissions are not suitable for lightweight applications, etc., and achieve simple design, small mass and volume, The effect of wide shifting range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

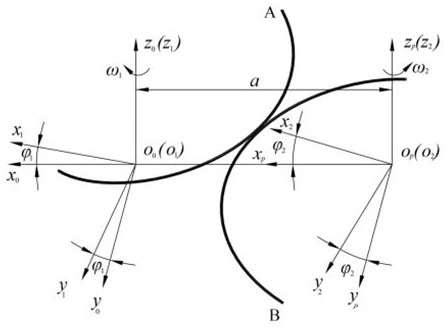

Method used

Image

Examples

Embodiment 1

[0065] The parameters of the given initial driving wire gear and driven wire gear are as follows:

[0066] The number of teeth of the driving wheel is 2 teeth, the diameter of the wire teeth is 3mm, the initial pitch is 120mm, and the length of the wire teeth is 2π; the number of teeth of the driven gear is 2 teeth, the diameter of the wire teeth is 3mm, the initial pitch is 120mm, and the length of the wire teeth is 2π;

[0067]

[0068] The equation of the driven contact line in its own coordinate system is:

[0069]

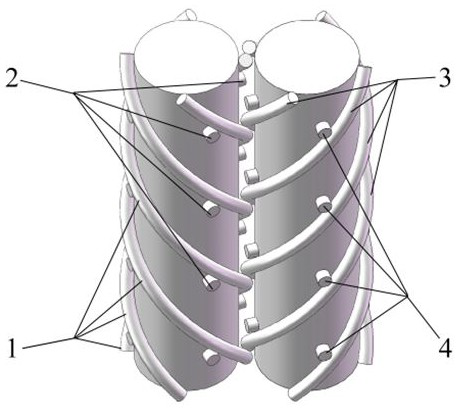

[0070] During the initial conditions, the transmission ratio of the gear pair of the example 1 is 1:1, and the actual effect is as follows figure 2 shown.

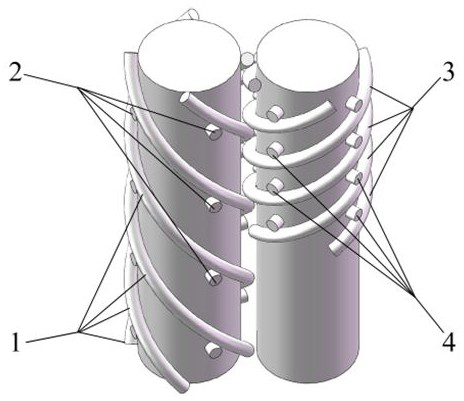

[0071] Further, change the pitch of the driven wheel so that the pitch of the contact line of the driven wheel changes to 60mm, and the pitch of the driving wheel does not change to 120mm. At this time, the equations of the active contact line and the driven contact line are:

[0072]

[0073] ...

Embodiment 2

[0082] Given that the initial number of teeth on the driving wheel is 4 teeth, the diameter of the wire teeth is 3mm, the initial pitch is 100mm, and the length of the wire teeth is 2π; the initial number of teeth on the driven gear is 2 teeth, the diameter of the wire teeth is 3mm, the initial pitch is 100mm, and the length of the wire teeth is 2π; only by adjusting the driving wire teeth and the pitch of the driven wire teeth, the transmission ratios that can be realized in Embodiment 2 include 1:2, 1:4, 1:6, 1:8, 1:1, and 1:3.

Embodiment 3

[0084] Given that the initial number of teeth on the driving wheel is 4 teeth, the diameter of the wire teeth is 4mm, the initial pitch is 140mm, and the length of the wire teeth is 2π; the initial number of teeth on the driven gear is 4 teeth, the diameter of the wire teeth is 4mm, the initial pitch is 140mm, and the length of the wire teeth is 2π; only by adjusting the driving wire teeth and the pitch of the driven wire teeth, the transmission ratios that can be realized in Embodiment 3 include 1:1, 1:2, 1:3, 1:4, 2:1, 2:3, 3:1, 3:2, 3 :4, 4:1, 4:3.

[0085] The principle of the present invention is: according to the wire gear space conjugate curve meshing theory, the parallel axis gear pair equation can be designed; the wire gear pair with variable pitch of the wire gear is designed, and the relationship between the pitch ratio and the transmission ratio of the wire gear pair is analyzed to obtain The pitch ratio is directly related to the transmission ratio; and the change...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com