High-strength loosening prevention adjustable wrench

An adjustable wrench and anti-loosening technology, applied in the field of adjustable wrenches, can solve the problems that the adjustable wrench is not suitable for use with large tightening force, weak in structure, and prone to slipping.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

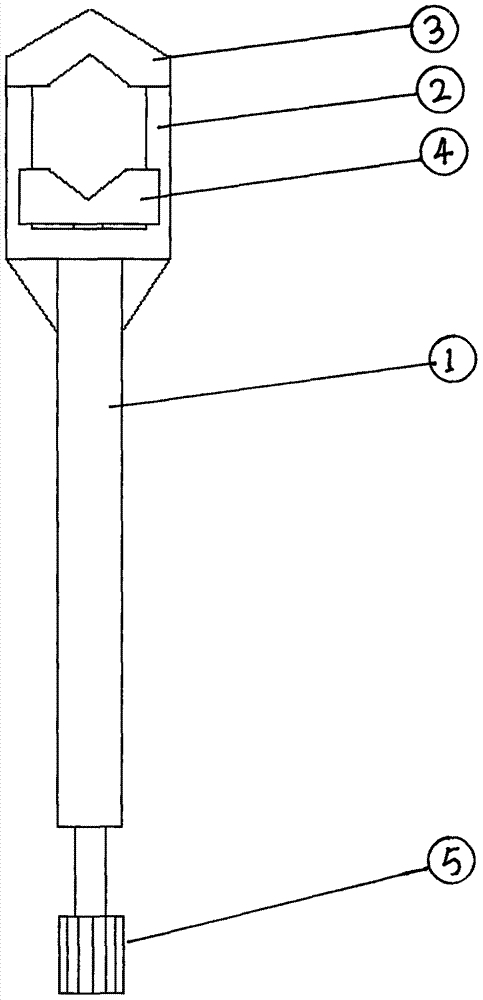

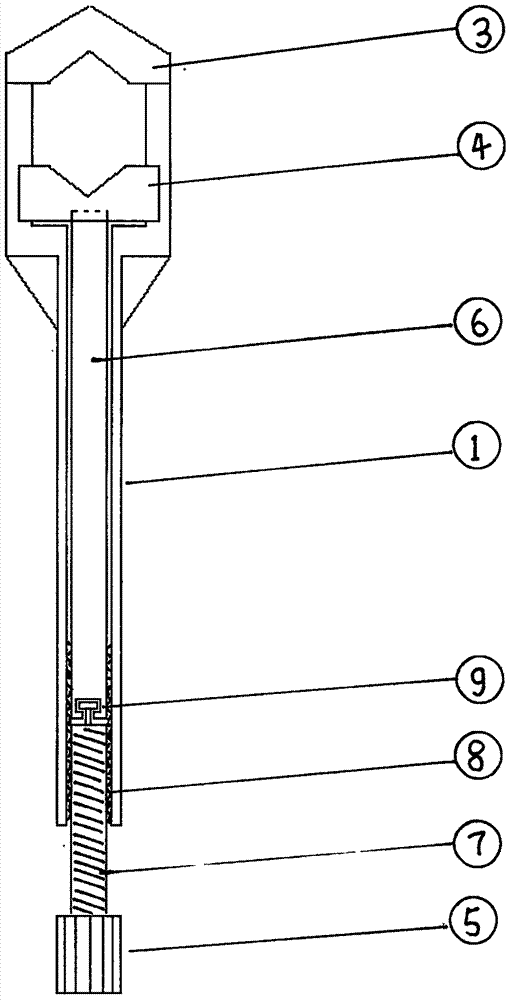

[0008] according to figure 1 It can be seen that the adjustable wrench is composed of a fixed block, a bracket, a slide block, a handle and an adjusting cap, the upper end of the handle (1) is provided with a support (2), the top of the support (2) has a fixed block (3), and the slide block (4) It can slide up and down under the limitation of the bracket (2). There is a groove on the contact surface between the fixed block (3) and the slider (4). The angle of the groove matches the angle of the hex nut. The handle ( The lower end of 1) is provided with an adjustment cap (5), and when the adjustment cap is rotated, the slider (4) can be raised through the push rod inside the handle (1).

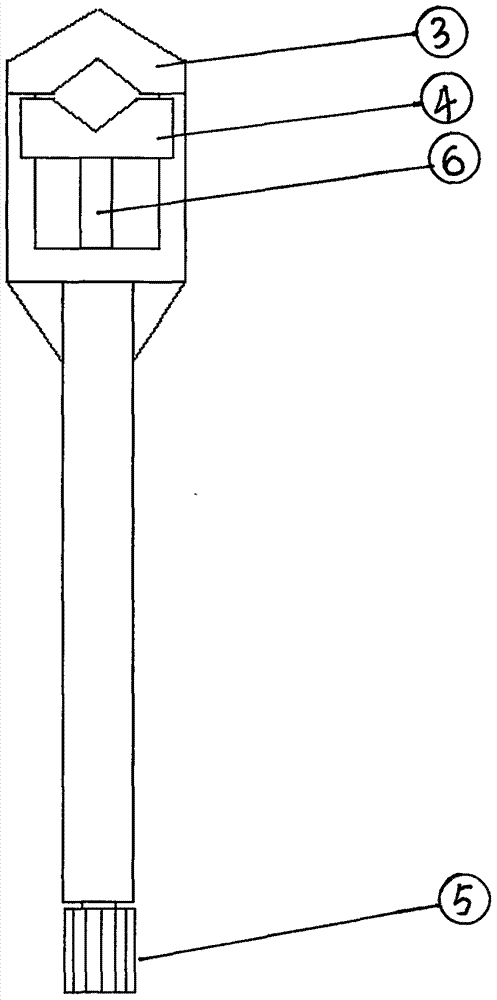

[0009] according to figure 2 It can be seen that when the adjusting cap (5) is turned, the slider (4) can be lifted up under the push of the push rod (6) inside the handle, and when the slider (4) and the fixed block (3) are closed, the middle The two opposite corners on the nut can be clam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com