Compression and compression integrated floor by floor

A manufacturing method and flooring technology, applied in the direction of wood compression, flat products, manufacturing tools, etc., can solve the problems of not considering the cross-section of wood, and achieve the effect of excellent quality, increased strength, and reduced overall deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

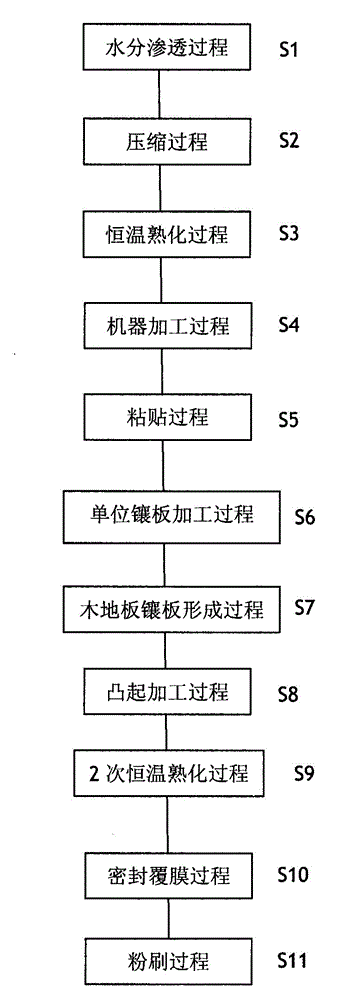

[0028] The production method of the actual operation of the present invention is divided into water penetration process S1, compression process S2, constant temperature curing process S3, machine processing process S4, pasting process S5, unit panel processing process S6, wooden floor panel production process S7, embossing Processing process S8, sealing coating process S10 and painting process S11.

[0029] In the water penetration process S1, the wood is soaked in flowing water for 15 days or the wood is infiltrated with steam, which is the process of treating the acidity of the wood in this way.

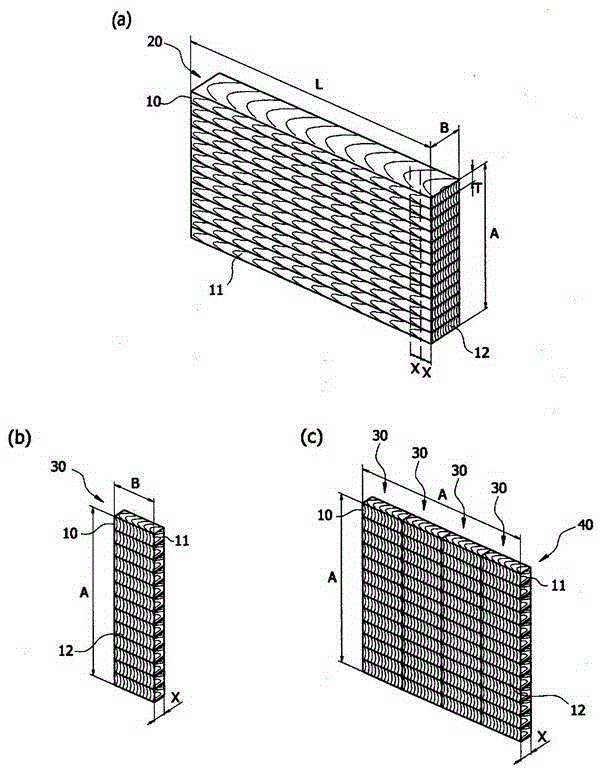

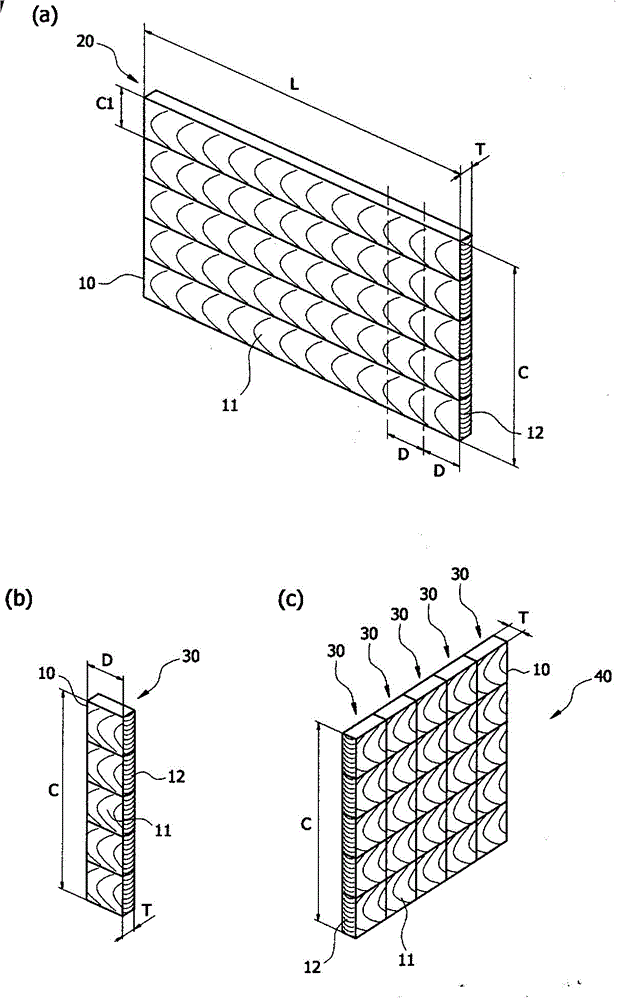

[0030] The compression process S2 is a method of compressing the wood that has been infiltrated with water through the water penetration process S1 with a hydraulic compressor, and compresses at a rate of 20% depending on the type of wood. After the wood is compressed in this way, the water, oil and mucus in the wood cell cavity will be squeezed out. Through this process, the dens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com