Polymer electrolyte and preparation method thereof and solid-state lithium-air battery

An air battery and electrolyte technology, applied in solid electrolytes, non-aqueous electrolytes, electrical components, etc., can solve problems such as inability to apply lithium-air batteries, polyethylene oxide failure, etc., to improve safety and stability, promote dissociation, The effect of excellent conductivity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032]The invention provides a method for preparing a polymer electrolyte, comprising the steps of:

[0033] S1. Preparation of metal-organic framework materials by solvothermal method;

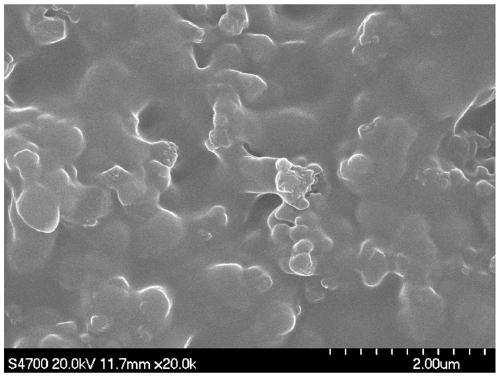

[0034] S2. Dissolving the lithium salt in the ionic liquid, and heating to remove water, to obtain a lithium-containing ionic liquid; mixing the metal-organic framework material prepared in step S1 with the lithium-containing ionic liquid according to a preset mass ratio, After heating and stirring, a composite filler is obtained;

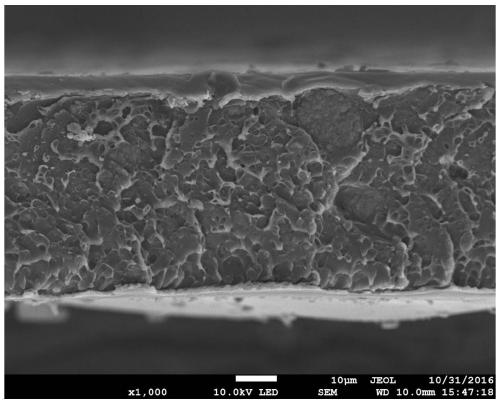

[0035] S3. Dissolving the polyether polyurethane elastomer in an organic solvent, then adding the composite filler obtained in step S2, and stirring thoroughly to obtain a homogeneous solution; uniformly coating the homogeneous solution on a polytetrafluoroethylene board and dry until the organic solvent is completely volatilized to obtain a polymer electrolyte.

[0036] In step S1, the preparation steps of the metal-organic framework material are as follows:

...

Embodiment 1

[0048] This embodiment provides a method for preparing a polymer electrolyte, comprising the following steps:

[0049] S1. Preparation of metal-organic framework materials by solvothermal method

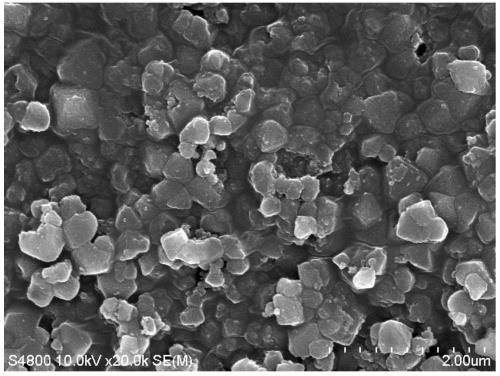

[0050] At room temperature, ultrasonically dissolve hafnium chloride (1.281 g, 4 mmol) and terephthalic acid (1.32 g, 8 mmol) in 24 mL of N,N-dimethylformamide (DMF), and add 0.665 mL of 12mol / L hydrochloric acid to generate more crystal nuclei, after ultrasonic stirring and dissolving, transfer the mixed solution into a 100mL high-pressure reactor lined with polytetrafluoroethylene. Then put the reaction kettle into a programmed temperature-controlled oven at a temperature of 1°C min -1 The heating rate is from room temperature to 120°C, after 24 hours of reaction, and then at 1°C·min -1 Cool down to room temperature. The product was filtered to obtain a white solid, which was rinsed three times with N,N-dimethylformamide and acetone respectively, activated and dried to obtain a ...

Embodiment 2

[0058] This embodiment provides a solid-state lithium-air battery, which includes a positive electrode, a negative electrode, and the polymer electrolyte prepared in Example 1. Among them, the positive electrode is an air electrode, and the negative electrode is a lithium metal sheet.

[0059] The air electrode is nickel foam loaded with commercial carbon nanotubes, and its preparation method is as follows: mix 90mg commercial carbon nanotubes, 5mg polytetrafluoroethylene emulsion and 10mL N-methylpyrrolidone evenly, and stir with a homogenizer to form slurry, and with a caliber of 0.3mm spray gun, the slurry is sprayed on the nickel foam.

[0060] The electrical performance of the solid-state lithium-air battery provided in this embodiment is tested, and its charge-discharge curve and cycle test chart are respectively as follows image 3 and Figure 4 shown.

[0061] exist image 3 Among them, the curve a represents the change curve of the voltage with the test time, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com