Transistor and manufacturing method thereof

A manufacturing method, transistor technology, applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problems of failure to enter the THz gap, loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

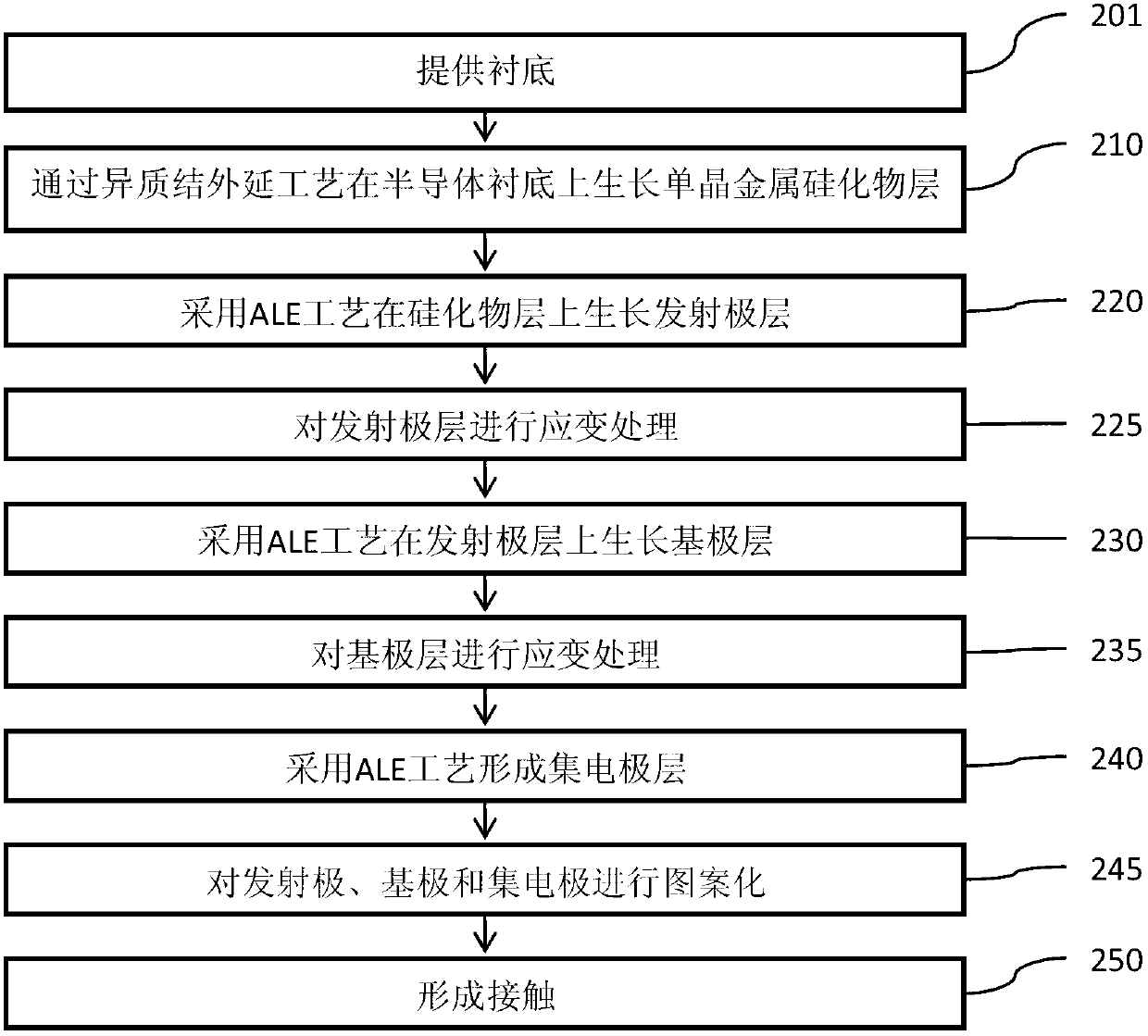

[0030] According to an embodiment of the present invention, a novel "inverted" silicon-germanium heterojunction bipolar transistor (SiGeHBT) device capable of penetrating into the terahertz gap (THzgap) frequency band from the microwave direction is provided. By adopting revolutionary thin-film technology innovations related to materials, process technologies and device structures, such as NiSi grown on Si using solid-state reaction (SSR) epitaxy 2 and in NiSi 2 The atomic layer epitaxy method is used to grow Si etc. to prepare SiGeHBT. The HBT device can work in the terahertz gap frequency band.

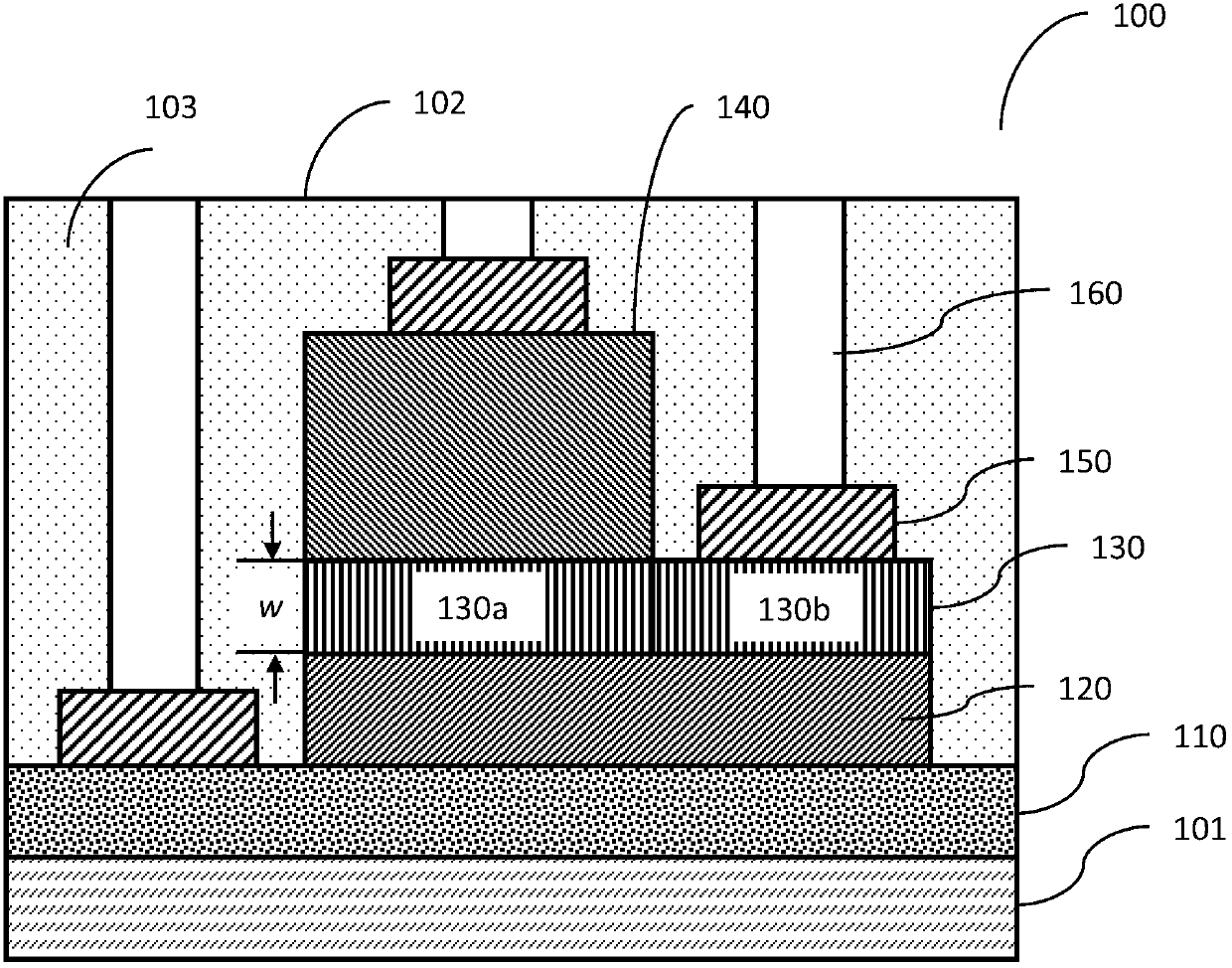

[0031] figure 1 is a schematic cross-sectional view of an inverted HBT 100 according to one embodiment of the present invention. Such as figure 1 As shown, the inverted HBT 100 includes an epitaxial layer 110 on a semiconductor (eg, silicon) substrate 101, an emitter 120 on the epitaxial layer 110, a base 130 on the emitter 120, and a collector 140 . Therefore, the order of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com