Method for producing light-emitting device

一种发光装置、制造方法的技术,应用在化学仪器和方法、半导体/固态器件制造、气态化学镀覆等方向,能够解决降低放射强度、易劣化等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 3

[0091] Figure 13 Is a schematic diagram showing an example of a specific light-emitting device in Embodiment 3 of the present invention;

[0092] Figure 14A Is description Figure 13 Diagram of an example manufacturing process of a light-emitting device;

[0093] Figure 14B Yes to continue Figure 14A Diagram of processing steps;

[0094] Figure 14C Yes to continue Figure 14B Diagram of processing steps;

[0095] Figure 15 It is a schematic diagram of corundum crystal structure;

[0096] Figure 16A Is a schematic diagram illustrating the operation of the method for manufacturing a light-emitting device according to the third embodiment of the present invention;

[0097] Figure 16B Is description Figure 16A Diagram of subsequent operations;

[0098] Figure 16C Is description Figure 16B Diagram of subsequent operations;

[0099] Figure 16D Is description Figure 16C Diagram of subsequent operations;

[0100] Figure 17 is an example Figure 14A~14C The diagram of...

Embodiment 1

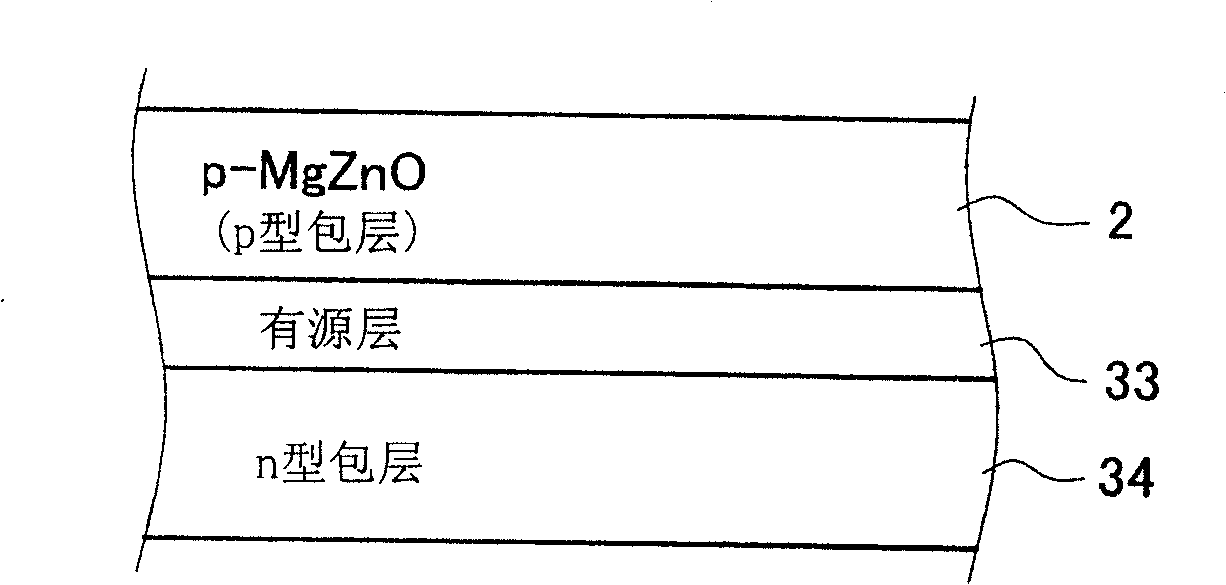

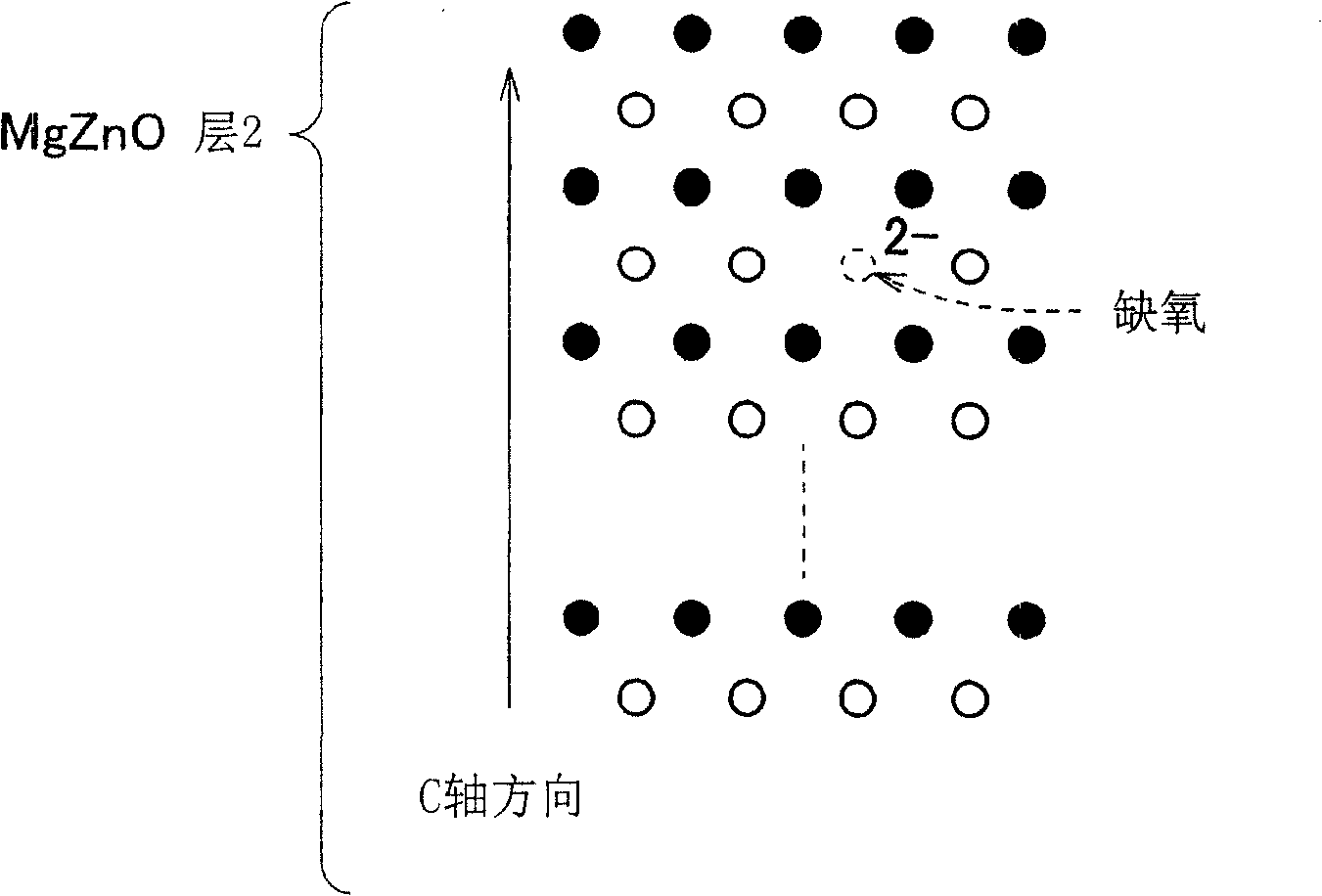

[0113] figure 1 The stacking structure of an important part of the light-emitting device of the first invention is schematically shown. The device has a light-emitting layer portion in which an n-type cladding layer 34, an active layer 33, and a p-type cladding layer 2 are sequentially stacked. P-type cladding 2 is composed of p-type Mg x Zn 1-x O layer (0≤x≤1): sometimes referred to as p-type MgZnO layer 2 hereinafter. In the p-type MgZnO layer 2, a trace amount of one, two or more of N, Ga, Al, In, and Li is included as p-type dopants: as described above, the p-type carrier concentration is adjusted to 1×10 16 ~8×10 18 Place / cm 3 Within the range, especially 10 17 ~10 18 Place / cm 3 Within the range of the left and right.

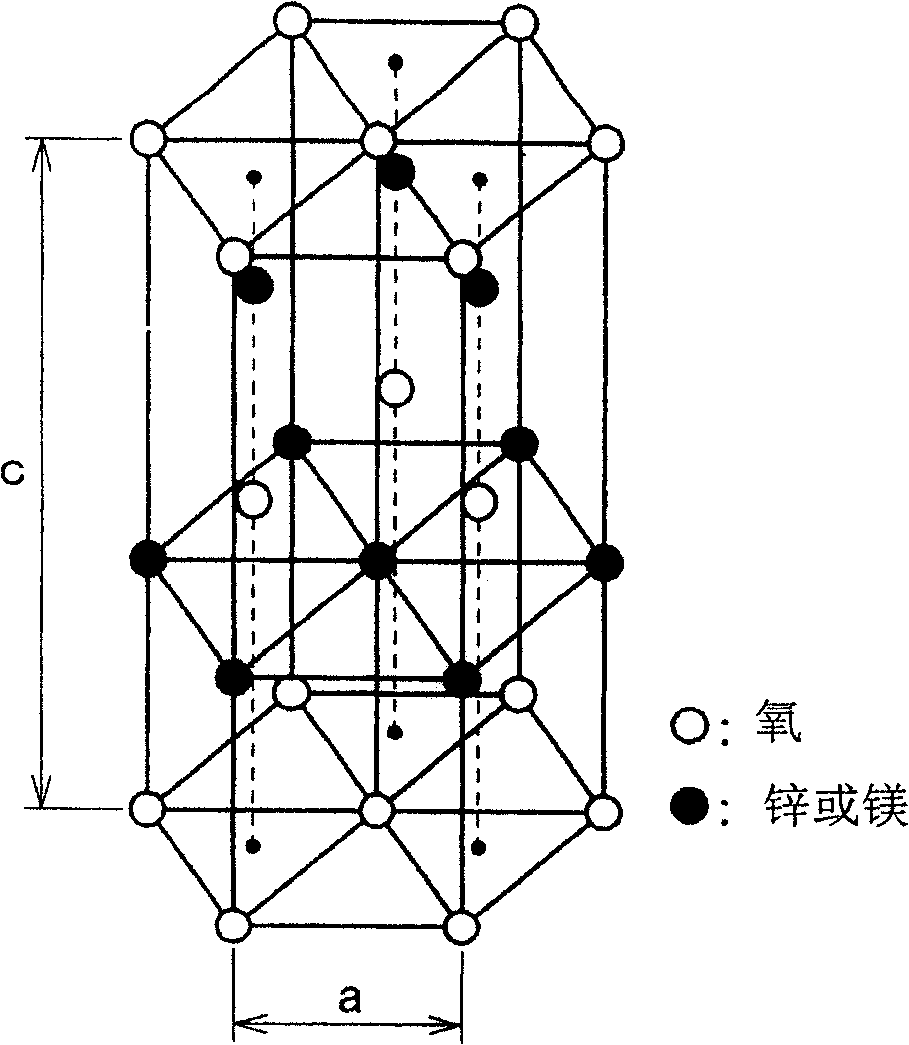

[0114] figure 2 It is a schematic diagram of the crystal structure of MgZnO, showing the so-called Wurtzite structure. In this structure, the oxygen ion filling plane and the metal ion (Zn or Mg ion) filling plane are alternately stacked along the c-axis d...

Embodiment 2

[0163] An embodiment of the second invention will be described below. Because the basic part of the light-emitting device to which the second invention is applied is the same as that described in Embodiment 1, it will not be described in detail (see figure 1 ~4 and Figures 10A and 10B). Such as Figure 6 As shown in (a), the GaN buffer layer 11 is still epitaxially grown on the sapphire substrate 10, and then a p-type MgZnO layer 52 (typically 50nm thick), MgZnO active layer 53 (typically 30nm thick) and n Type MgZnO layer 54 (generally 50 nm thick) (the reverse is also possible). The epitaxial growth of each layer in this example can be performed by the MOVPE process similar to that described in Embodiment 1, but there are several differences as follows. More specifically, when the MgZnO active layer 53 and the p-type MgZnO layer 52 are grown here, an ultraviolet lamp (such as an excimer ultraviolet lamp) as an ultraviolet light source is provided on the main surface of the oppo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| band gap | aaaaa | aaaaa |

| band gap | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com