Production method for light emitting element

A technology of light-emitting device and light-emitting layer, which is applied in chemical instruments and methods, semiconductor/solid-state device manufacturing, crystal growth, etc., and can solve the problems of reducing radiation intensity and easy deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 3

[0092] Figure 13 It is a schematic diagram showing an example of a specific light-emitting device in Embodiment 3 of the present invention;

[0093] Figure 14A is description Figure 13 A diagram of an example manufacturing process for a light emitting device;

[0094] Figure 14B is to continue Figure 14A The processing steps diagram;

[0095] Figure 14C is to continue Figure 14B The processing steps diagram;

[0096] Figure 15 is a schematic diagram of the corundum crystal structure;

[0097] Figure 16A is a schematic diagram illustrating the operation of the light-emitting device manufacturing method according to Embodiment 3 of the present invention;

[0098] Figure 16B is description Figure 16A A diagram of subsequent operations;

[0099] Figure 16C is description Figure 16B A diagram of subsequent operations;

[0100] Figure 16D is description Figure 16C A diagram of subsequent operations;

[0101] Figure 17 is an example Figures 14A-14...

Embodiment 1

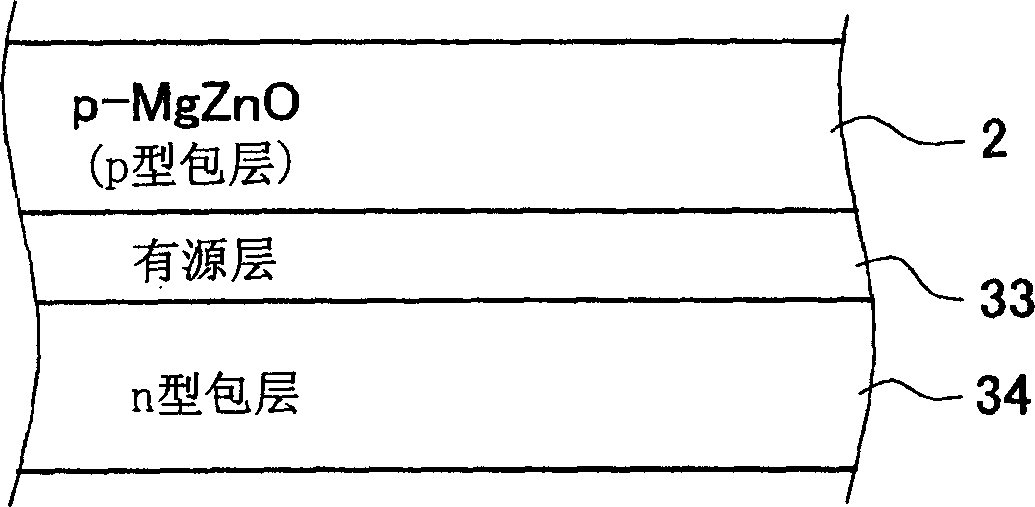

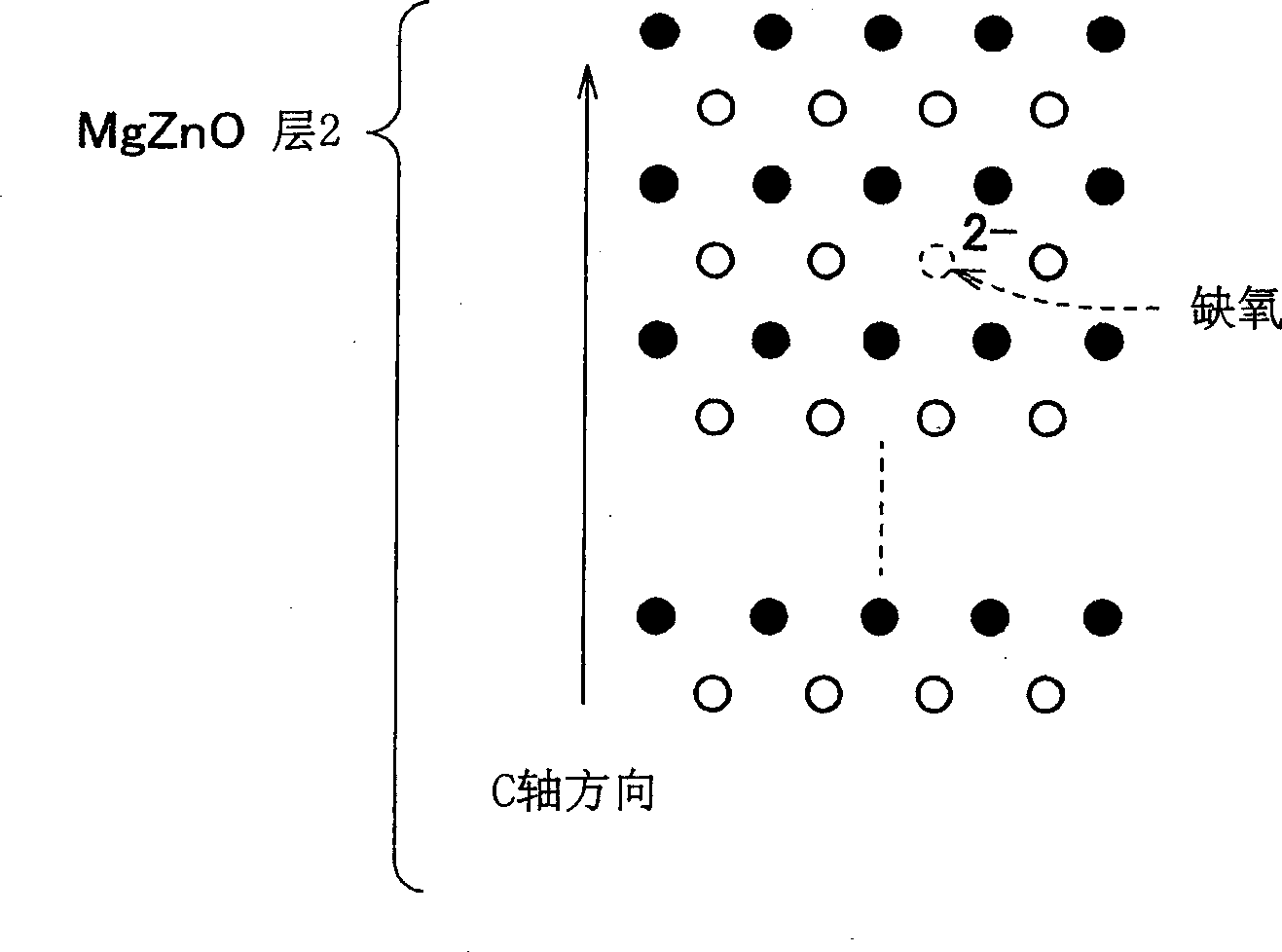

[0114] figure 1 Schematically showing the stacked structure of important parts of the light-emitting device of the first invention, the device has a light-emitting layer portion in which n-type cladding layer 34, active layer 33 and p-type cladding layer 2 are stacked in sequence. The p-type cladding layer 2 is composed of p-type Mg x Zn 1-x O layer (O≤x≤1): hereinafter sometimes referred to as a p-type MgZnO layer 2). In the p-type MgZnO layer 2, one, two or more of trace amounts of N, Ga, Al, In and Li are included as p-type dopants: as mentioned above, the p-type carrier concentration is adjusted in 1×10 16 ~8×10 18 place / cm 3 range, especially at 10 17 ~10 18 place / cm 3 within the range of left and right.

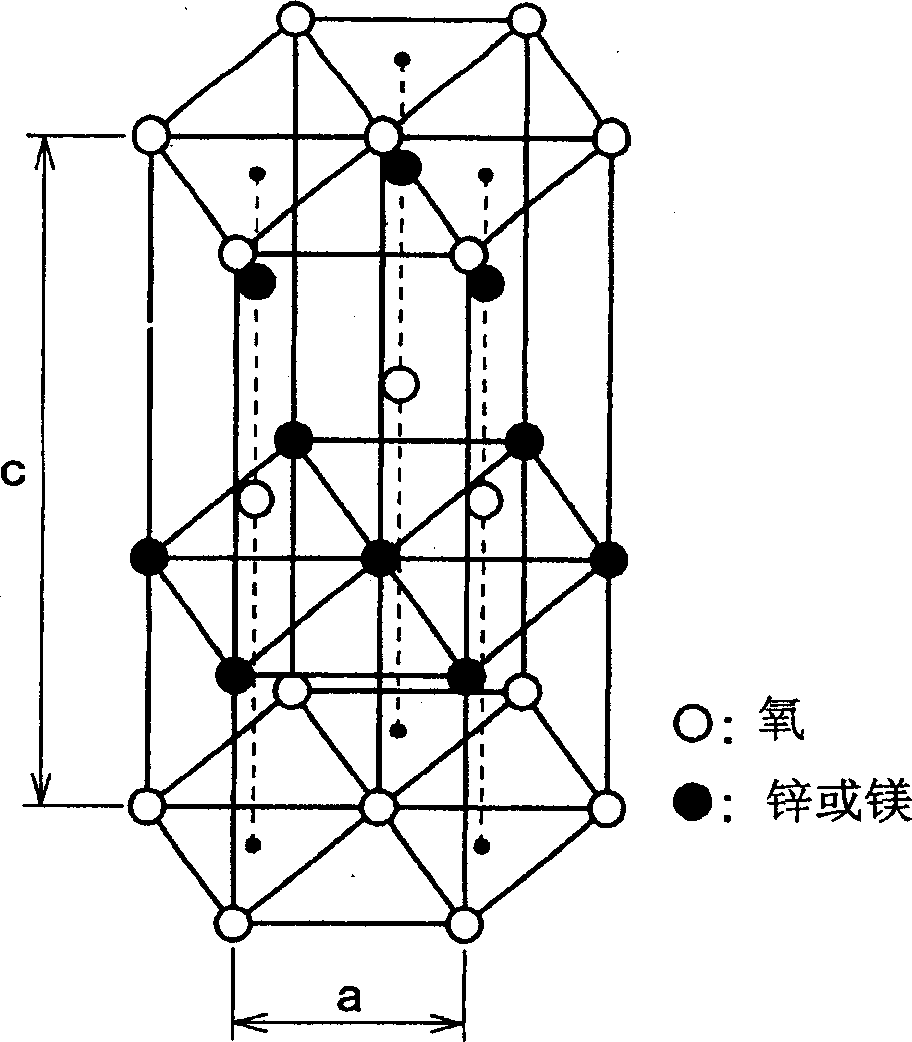

[0115] figure 2 is a schematic diagram of the crystal structure of MgZnO, showing the so-called Wurtzite structure. In this structure, the planes filled with oxygen ions and the planes filled with metal ions (Zn or Mg ions) are alternately stacked along the...

Embodiment 2

[0164] Embodiments of the second invention are described below. Because the basic part of the light-emitting device applicable to the second invention is the same as that described in Embodiment 1, it will not be described in detail (see Figure 1~4 with Figure 10A and 10B ). Such as Image 6 As shown in (a), the GaN buffer layer 11 is epitaxially grown on the sapphire substrate 10, and then a p-type MgZnO layer 52 (generally 50 nm in thickness), an MgZnO active layer 53 (generally 30 nm in thickness) and n Type MgZnO layer 54 (generally 50nm in thickness) (it is also possible to grow in reverse). The epitaxial growth of each layer in this example can be performed by a MOVPE process similar to that described in Example 1, but with the following points of difference. More specifically, when growing the MgZnO active layer 53 and the p-type MgZnO layer 52, an ultraviolet lamp (such as an excimer ultraviolet lamp) as an ultraviolet light source is arranged on the main surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com