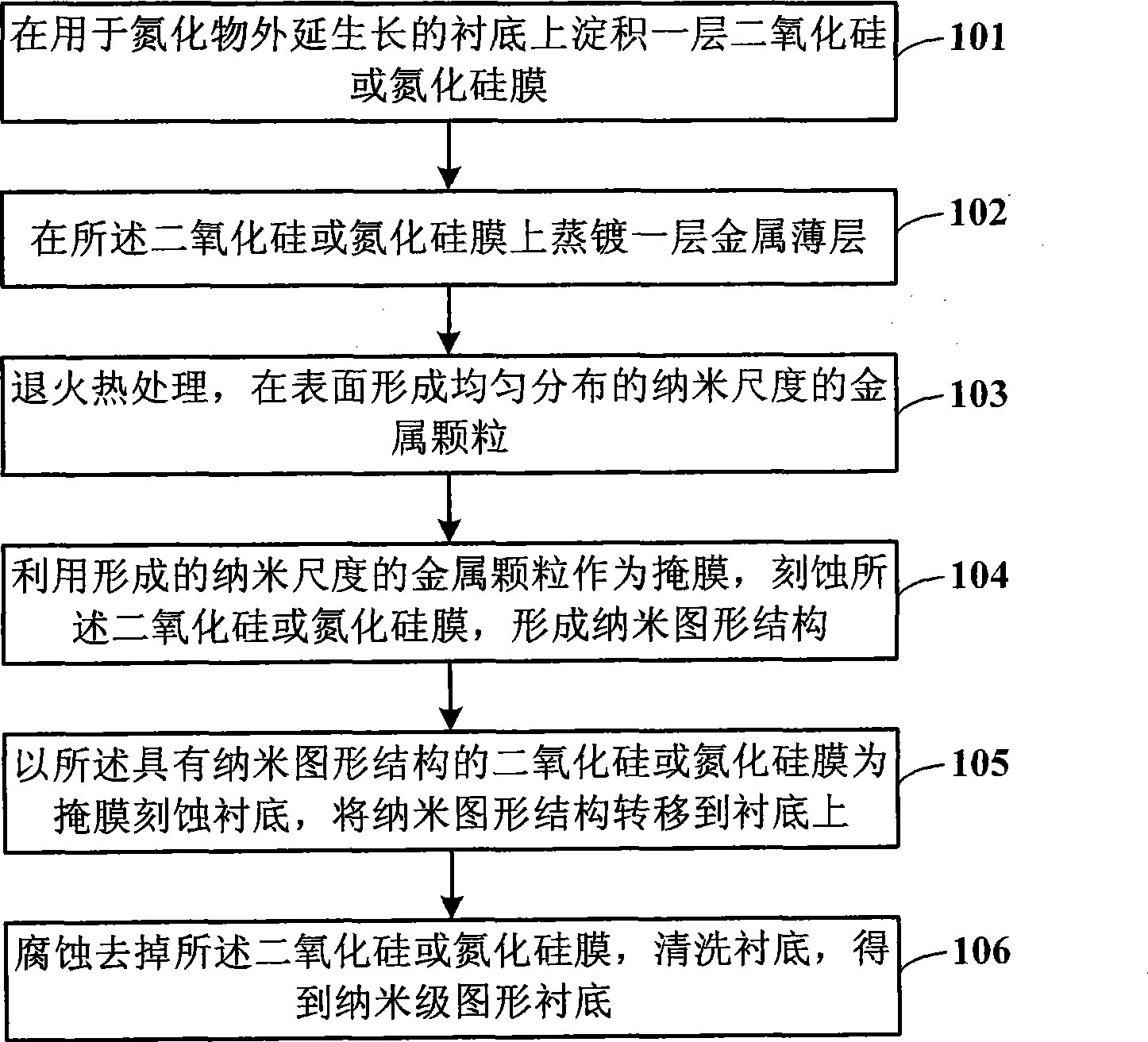

Method for preparing nano-scale pattern substrate for nitride epitaxial growth

An epitaxial growth, patterned substrate technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of large area, large-scale production, expensive equipment, complex process, etc. The effect of large area production and reduced production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] This embodiment is a method for fabricating a nanoscale patterned sapphire substrate for nitride epitaxial growth. Sapphire substrate is one of the most commonly used substrate materials for epitaxial nitride growth.

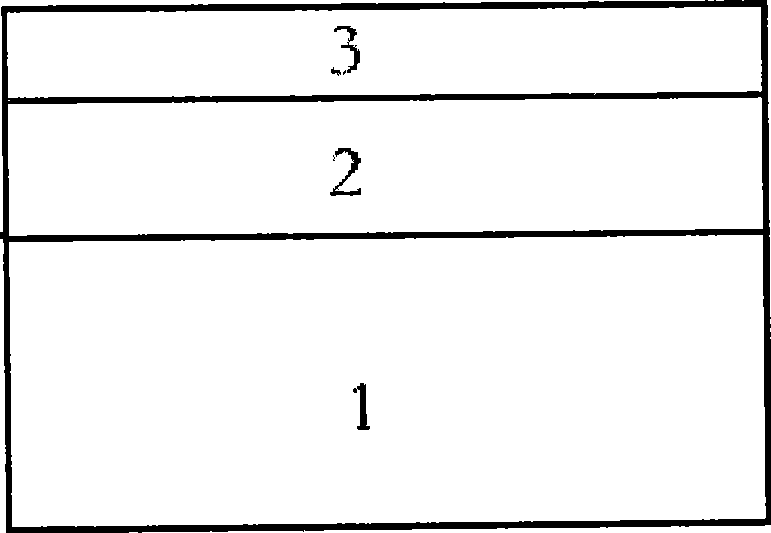

[0053] First, a 0.5-micron silicon dioxide film is deposited on a 2-inch sapphire substrate by plasma-enhanced chemical vapor deposition (PECVD), and then a 15-nm nickel metal layer is evaporated by electron beam evaporation. The structure profile is as follows: figure 2 shown;

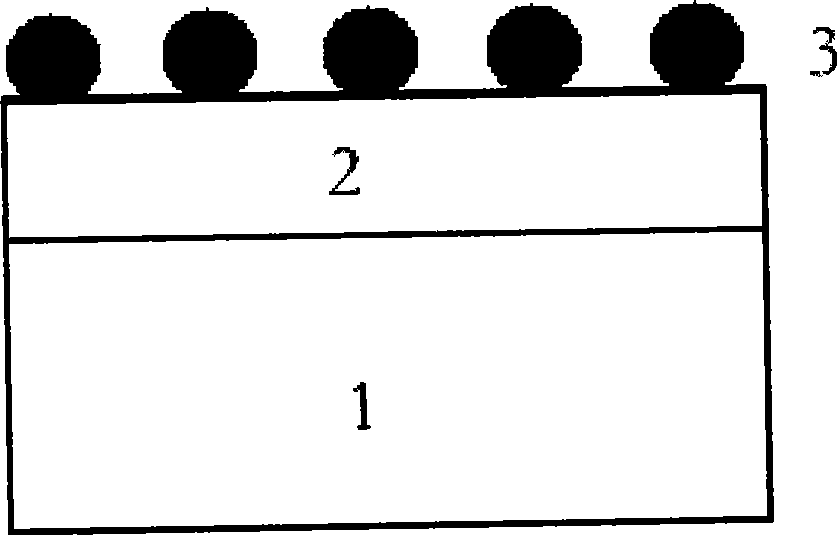

[0054] Then in the flowing N 2 , and annealed at 850 degrees for 5 minutes to form nanoscale nickel metal particles on the surface. The structure profile is as follows image 3 shown;

[0055] Then use nano-scale nickel metal particles as a mask, and use RIE or ICP plasma etching equipment to dry-etch the silicon dioxide film to form a nano-pattern structure. The scale of the pattern is about 50-150nm, and the structure profile is Figure 4 shown;

[0056] Then use the sili...

Embodiment 2

[0059] This embodiment is a method for fabricating a nanoscale patterned Si(111) substrate for nitride epitaxial growth. Si(111) substrate is one of the commonly used substrate materials for epitaxial nitride growth.

[0060] First, a 0.5 micron silicon nitride film is deposited on a Si(111) substrate by PECVD technology and a 15nm titanium (Ti) metal thin layer is evaporated by electron beam method. The structure profile is as follows: figure 2 shown;

[0061] Then in the flowing N 2 Annealing at 950°C for 20 minutes to form nanoscale titanium (Ti) metal particles with a structural profile such as image 3 shown;

[0062] Then use nanometer-scale metal titanium (Ti) particles as a mask, and use RIE or ICP equipment to dry-etch the silicon nitride film to form a nano-graphic structure. The graphic scale is about 100-300nm, and the structural section is as follows Figure 4 shown;

[0063] Then use the silicon nitride film of the nano-pattern structure as a mask, and use ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com