Solar cell sheet electric sheet-splitting device

A technology of solar cells and fragments, which is applied in the direction of circuits, electrical components, sustainable manufacturing/processing, etc., and can solve the problems of low artificial fragmentation efficiency and high fragmentation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the content of the present invention easier to be understood clearly, the present invention will be described in further detail below according to specific embodiments and in conjunction with the accompanying drawings.

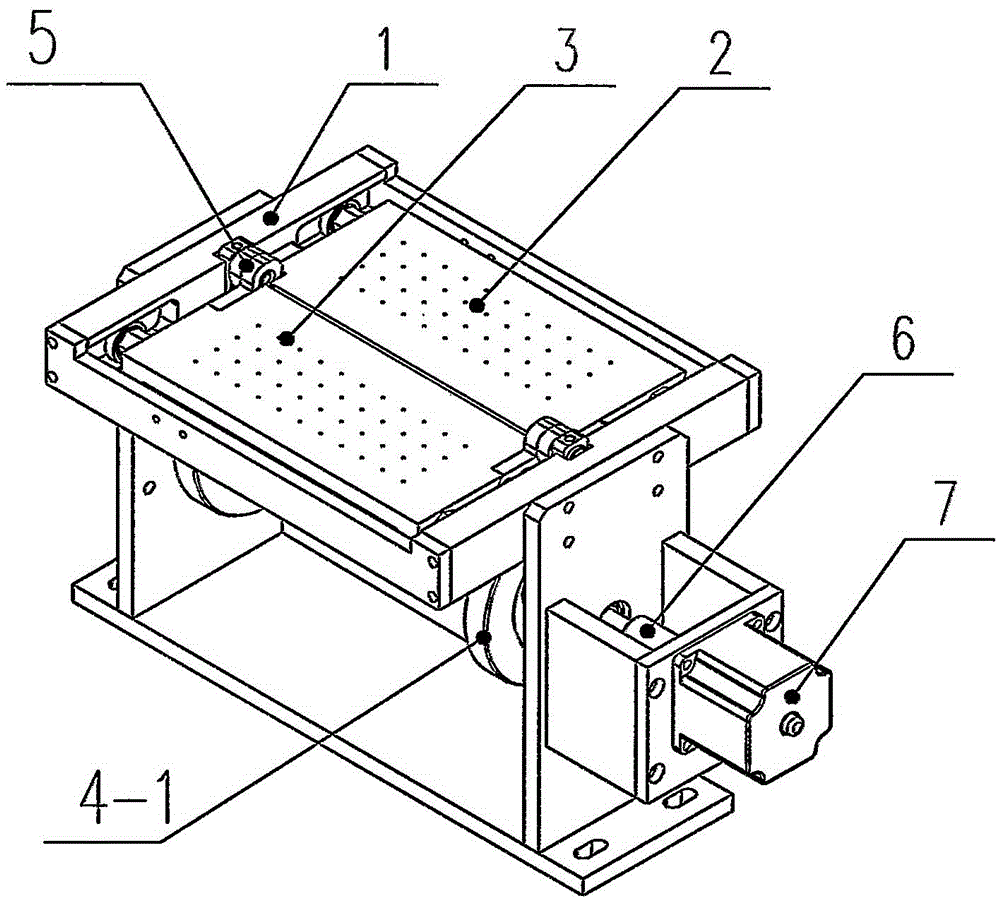

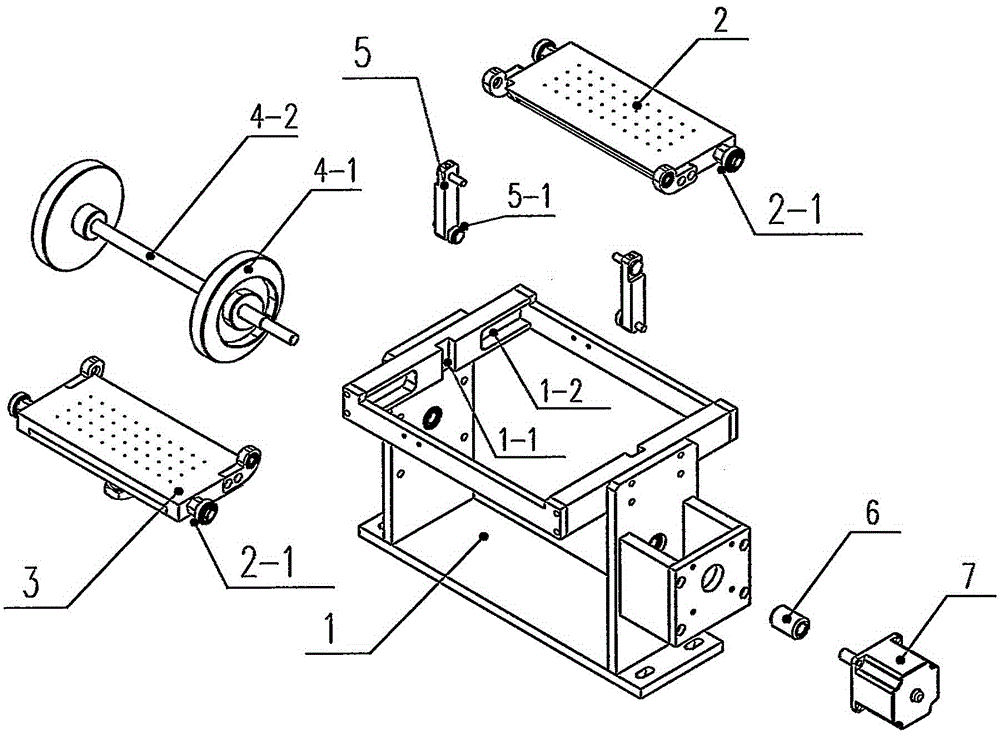

[0020] like Figures 1~7 As shown, an electric splitting device for solar cells includes a frame 1, a left split plate 3, a right split plate 2 and a connecting rod 5 slidingly fitted on the frame 1 and driving the connecting rod 5 to do The cam drive mechanism of vertical reciprocating linear movement, one end of the left split plate 3 is slidably fitted on one side of the frame 1, one end of the right split plate 2 is slidably fitted on the other side of the frame 1, the other end of the left split plate 3, The other end of the right split plate 2 and one end of the connecting rod 5 are hinged together.

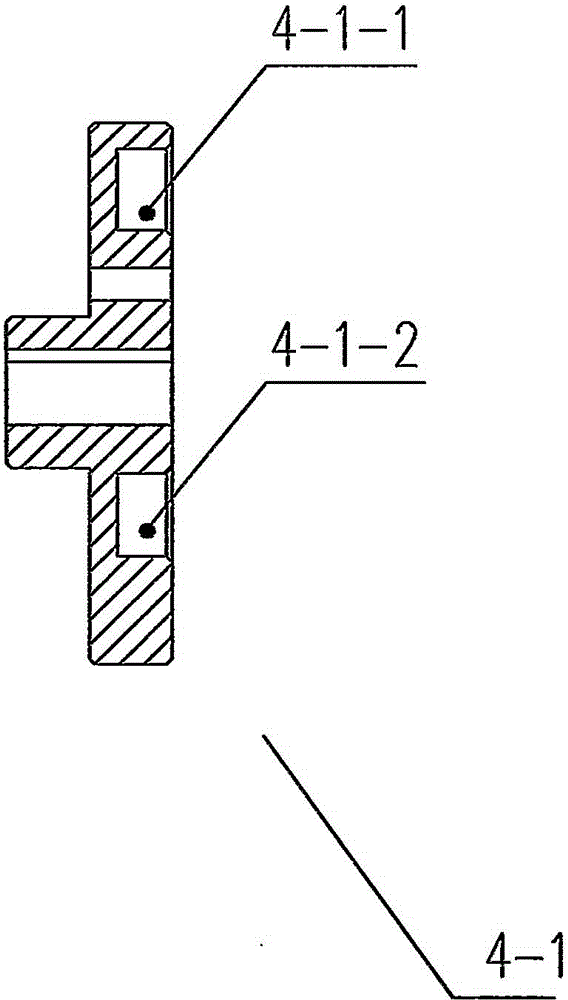

[0021] like figure 2 As shown, there is a vertical chute 1-1 in the middle of the rack 1, and the connecting rod 5 is slidably f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com