Polysilicon solar battery slice etching device

A technology for solar cells and polysilicon, which is used in circuits, electrical components, and final product manufacturing. Avoid the possibility of cross-contamination and the safety of production, reduce heat loss, and avoid the effect of oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and examples. The following description is only for understanding the technical solution of the present invention, and is not intended to limit the scope of the present invention.

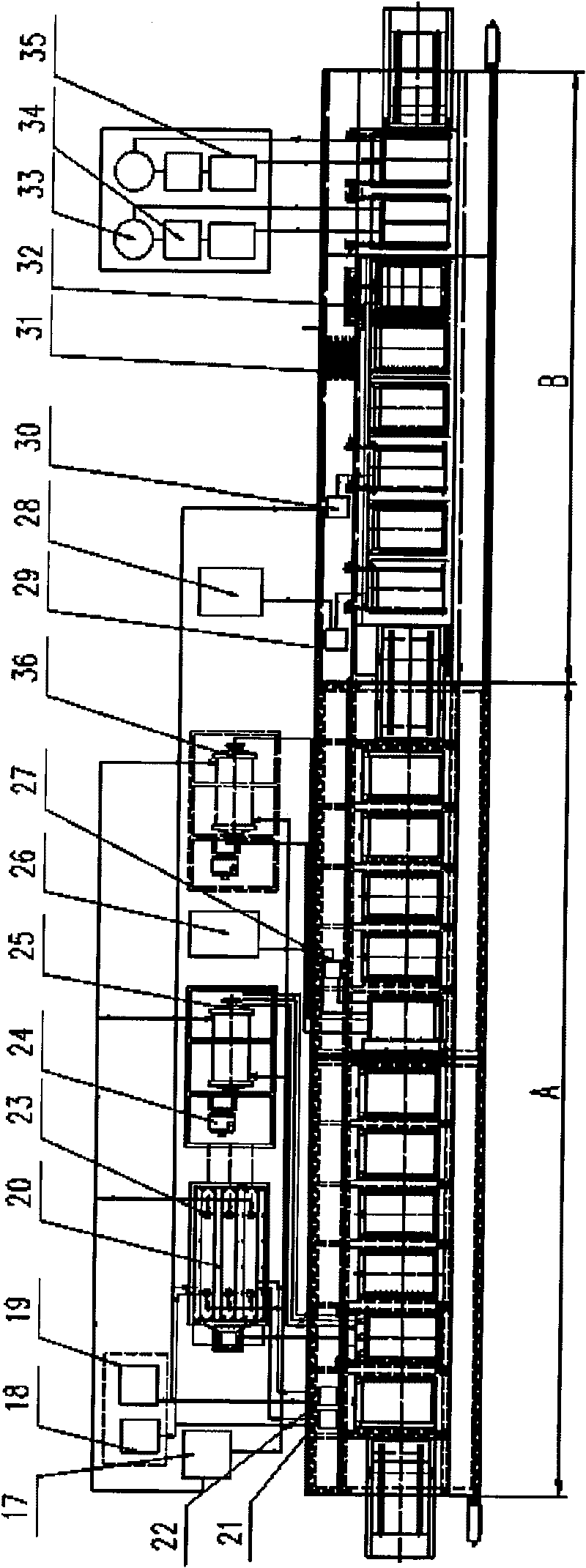

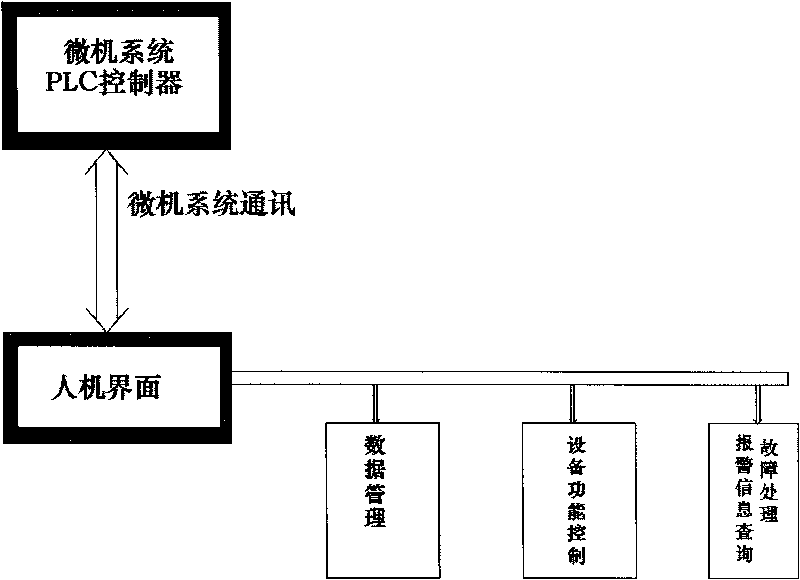

[0022] The polysilicon solar cell texturing equipment provided by the present invention comprises: a polysilicon solar cell texturing part, a polysilicon solar cell pickling part and a microcomputer control system, and the polysilicon solar cell texturing part and the polysilicon solar cell pickling part are all connected To the microcomputer control system, the microcomputer control system can individually control or coordinate the control of the texturing part of the crystalline silicon solar cell and the pickling part of the polycrystalline silicon solar cell.

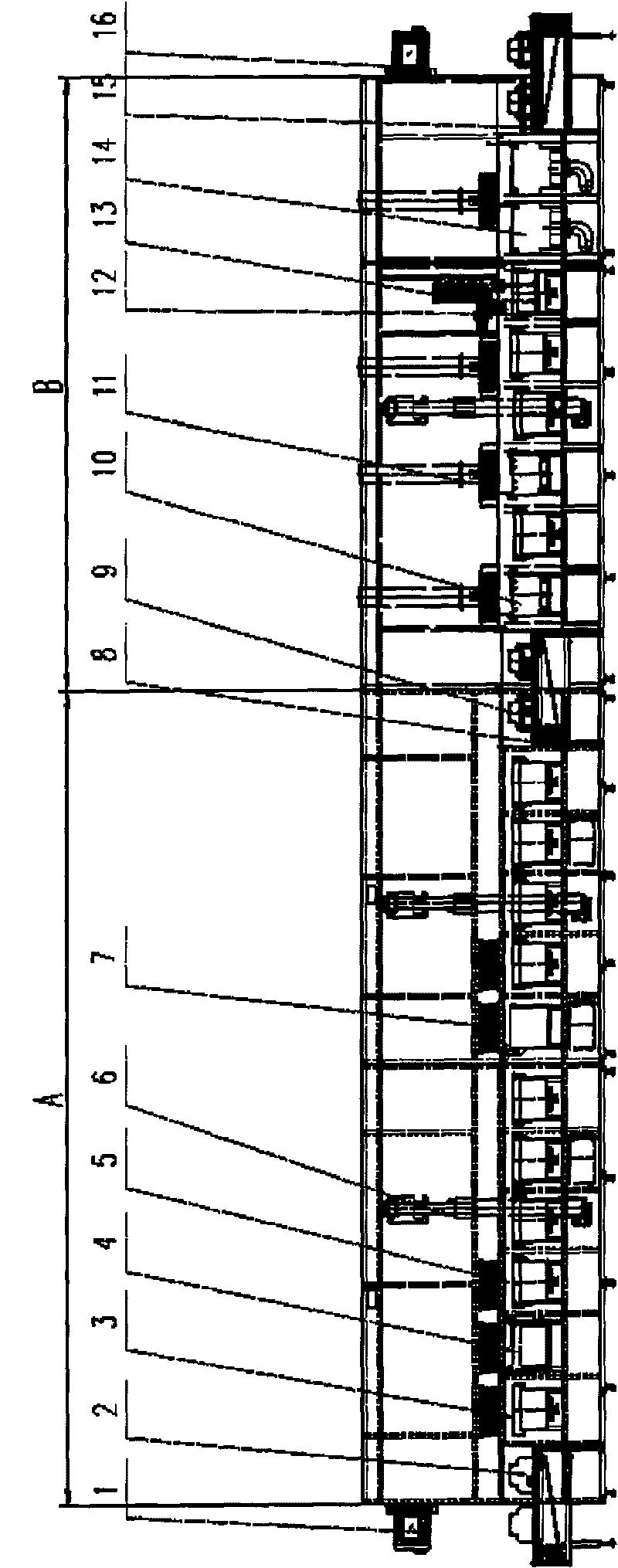

[0023] Such as figure 1 As shown, the polycrystalline silicon solar cell texturing part A includes: a feeding mechanism 2, a first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com