Defect detection and color sorting method of photovoltaic solar crystalline silicon cell, and system thereof

A technology for photovoltaic solar energy and crystalline silicon cells, which is used in optical testing for flaws/defects, optical instrument testing, and testing of machinery/structural components. effect of speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

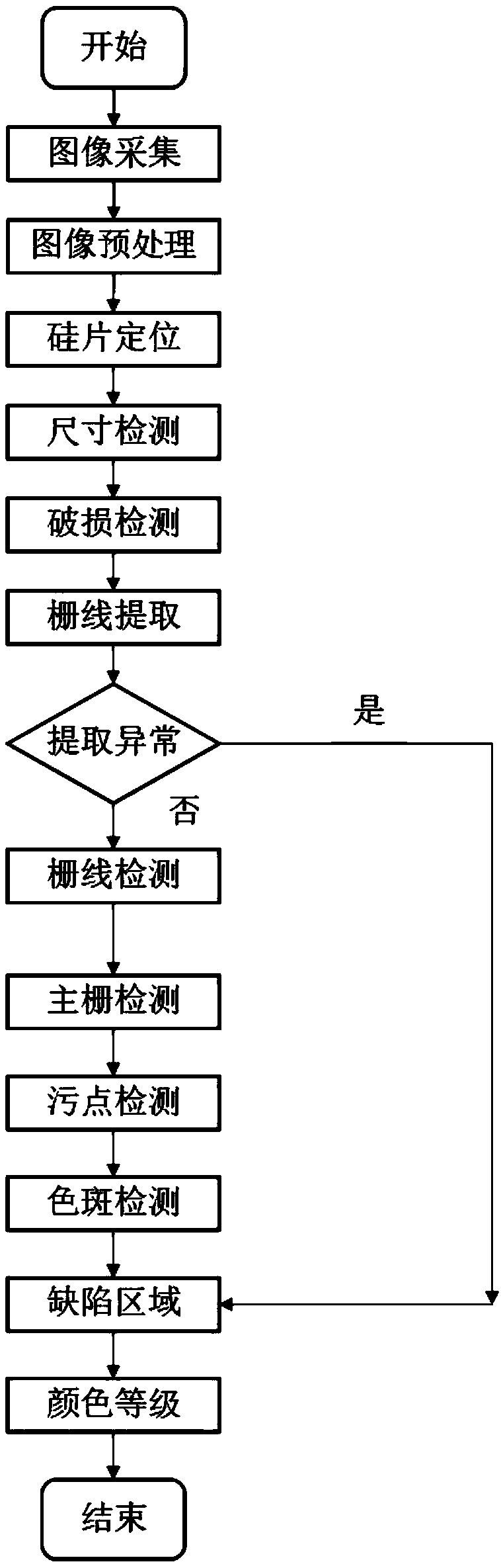

[0054] Such as figure 1 As shown, the defect detection and color sorting method of photovoltaic solar crystalline silicon cells includes the following steps:

[0055] S1. Collect the silicon wafer image and perform preprocessing, specifically collect the gray calibration plate image of the silicon wafer under red, green and blue light sources, perform light compensation on the image, and then perform color calibration on the light compensated image; Specifically include the following steps:

[0056] S11. Setting the luminous intensity of the red, green and blue light sources by controlling the light source controller;

[0057] S12. Use an industrial camera to separately collect images of calibration plates whose colors are gray under red, green, and blue light sources;

[0058] S13. Perform illumination compensation on the calibration plate image by collecting black and white images of three color light sources;

[0059] S14. Perform color calibration: collect images after ...

Embodiment 2

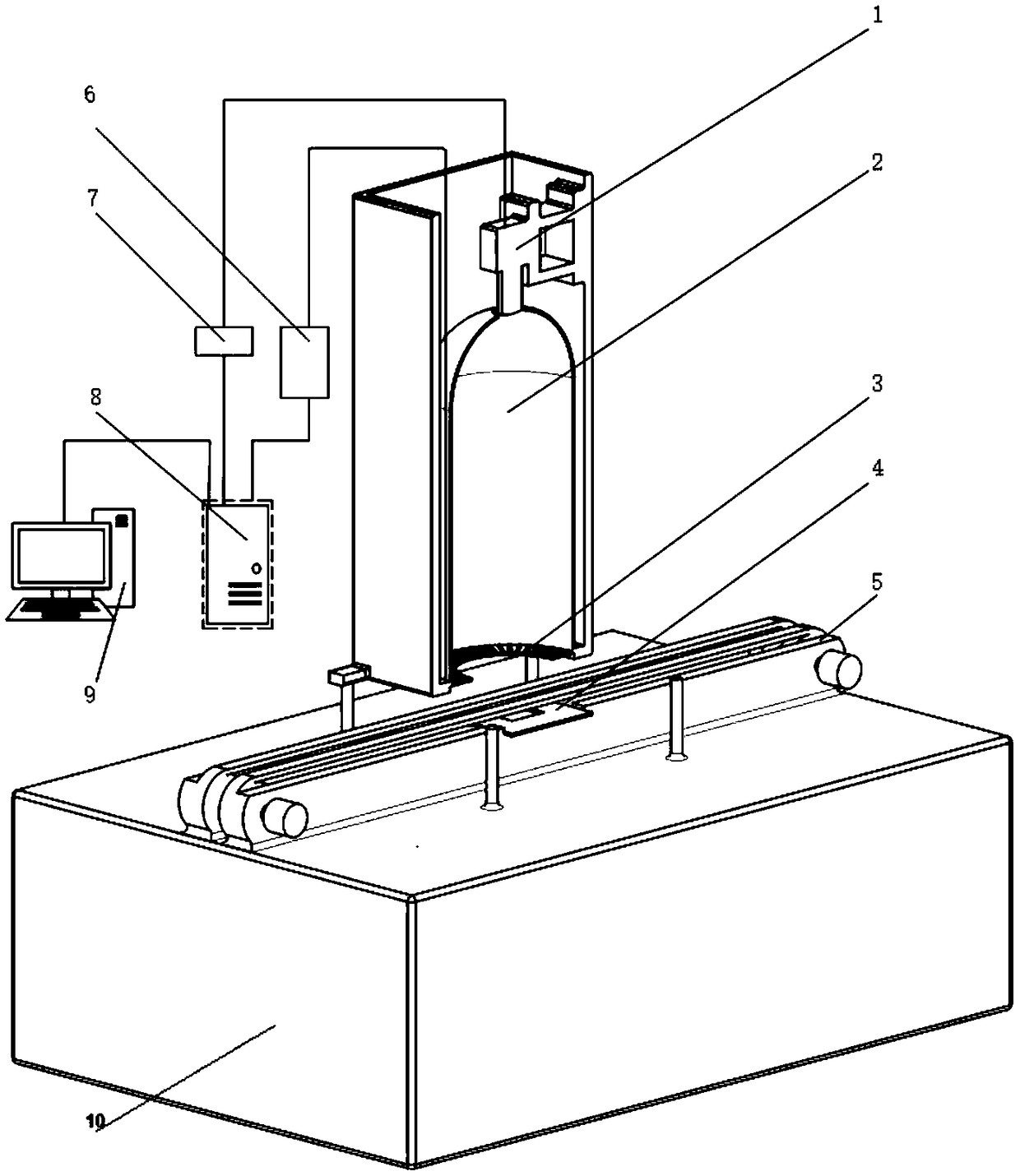

[0075] Such as figure 2As shown, the defect detection and color sorting system of photovoltaic solar crystalline silicon cells using the method described in Example 1, the defect detection and color sorting system includes: industrial camera 1, sealed box 2, LED light source 3, red backlight Board 4, transmission mechanism unit 5, light source controller 6, image acquisition card 7, industrial computer 8, host computer display 9, silicon chip to be tested, platform cabinet 10; the transmission mechanism unit 5 includes a bracket and a Conveyor belt; the industrial computer 8 includes a CPU, a display, and a memory;

[0076] The industrial computer 8 is connected to the light source controller 6, the image acquisition card 7, and the host computer display 9; the LED light source is a red, green and blue tricolor light source, and the light source controller 6 is connected to the LED light source 3 for controlling red, green and blue light sources. three kinds of light source ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com