Quantitative classification frame system of crude tobacco and frame technology of crude tobacco

A technology for framing and emptying cigarettes, which is applied in the fields of tobacco, tobacco preparation, loading/unloading, etc., and can solve the problems of low framing accuracy, automatic quantitative framing system, low degree of informatization, and many manual links

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

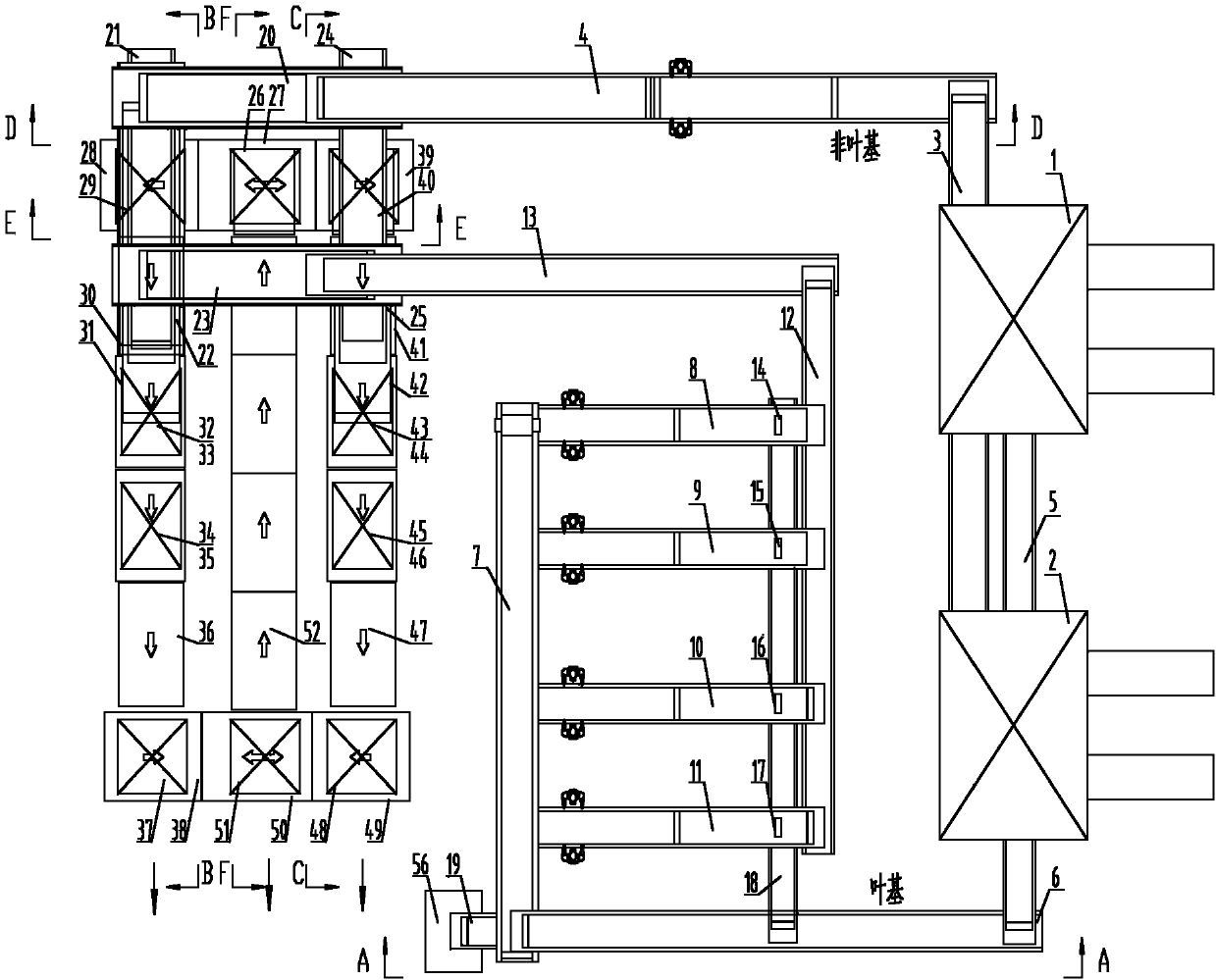

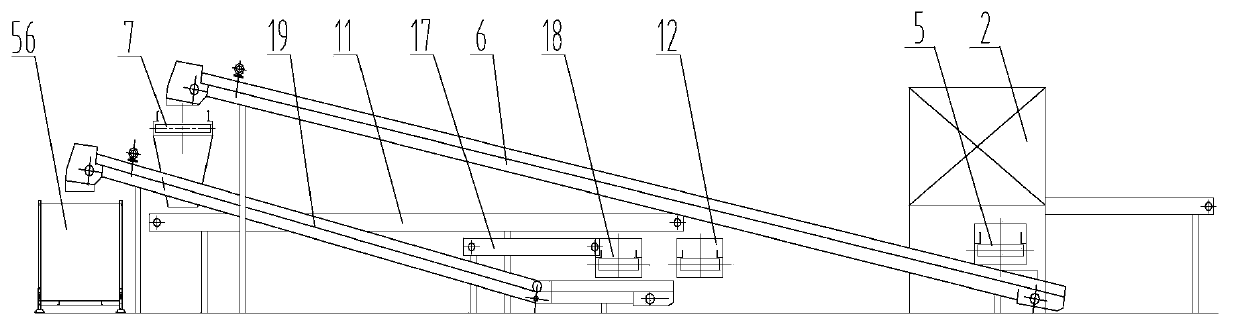

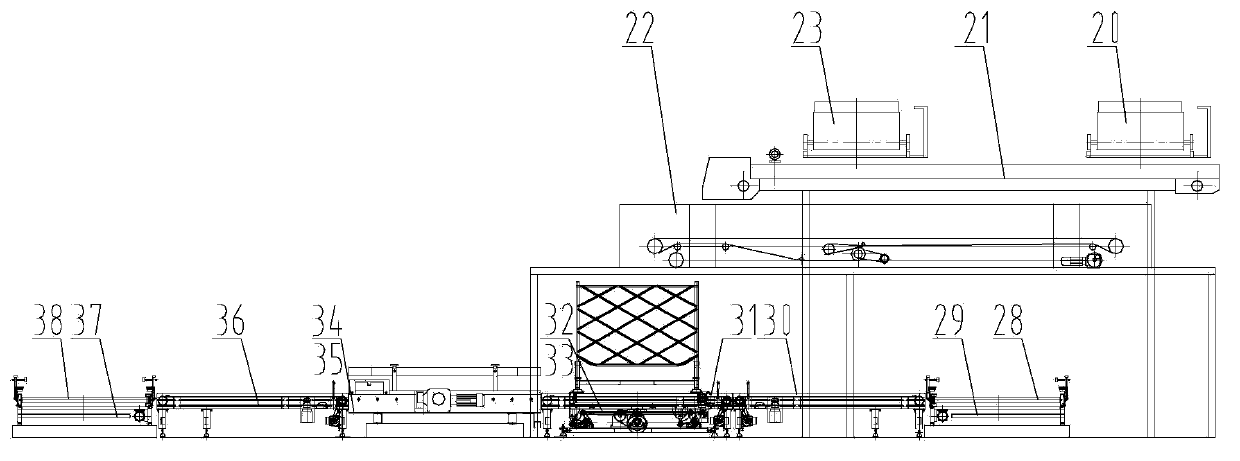

[0018] The invention provides a method for the pretreatment section of the threshing and redrying line in the tobacco industry. The original tobacco after being cut by a two-way leaf-matching cutting and unbarring machine can realize the classification of the leaf base and the non-leaf base part, respectively, and quantitatively frame them. , and can carry out mixed quantitative framing of leaf base and non-leaf base, and can ensure a certain quantitative framing accuracy, a system with information tracking and management functions. The two-way leaf arranging, cutting, and unbonding machine of the present invention means that the feed is divided into two paths, but at the same time, it enters a leaf arranging, cutting, and untangling machine to cut and untie, and the output is divided into two paths, but finally merged into one path. Such as Figure 1 to Figure 7 As shown, the raw tobacco sorting and quantitative framing system of the present invention includes a two-way leaf-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com