Ginkgo leaf-based porous carbon material loaded with ruthenium and preparation method and application thereof

A technology of porous carbon materials and carbon materials, applied in chemical instruments and methods, hydrogen production, physical/chemical process catalysts, etc., can solve the problems of general catalyst effect and small specific surface area of carbon black, and achieve good cycle performance, Broad application prospects and the effect of improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

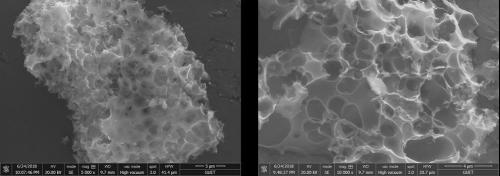

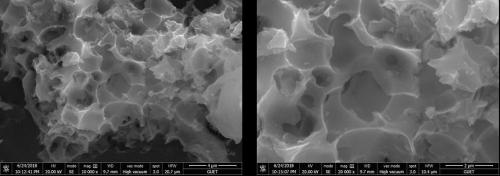

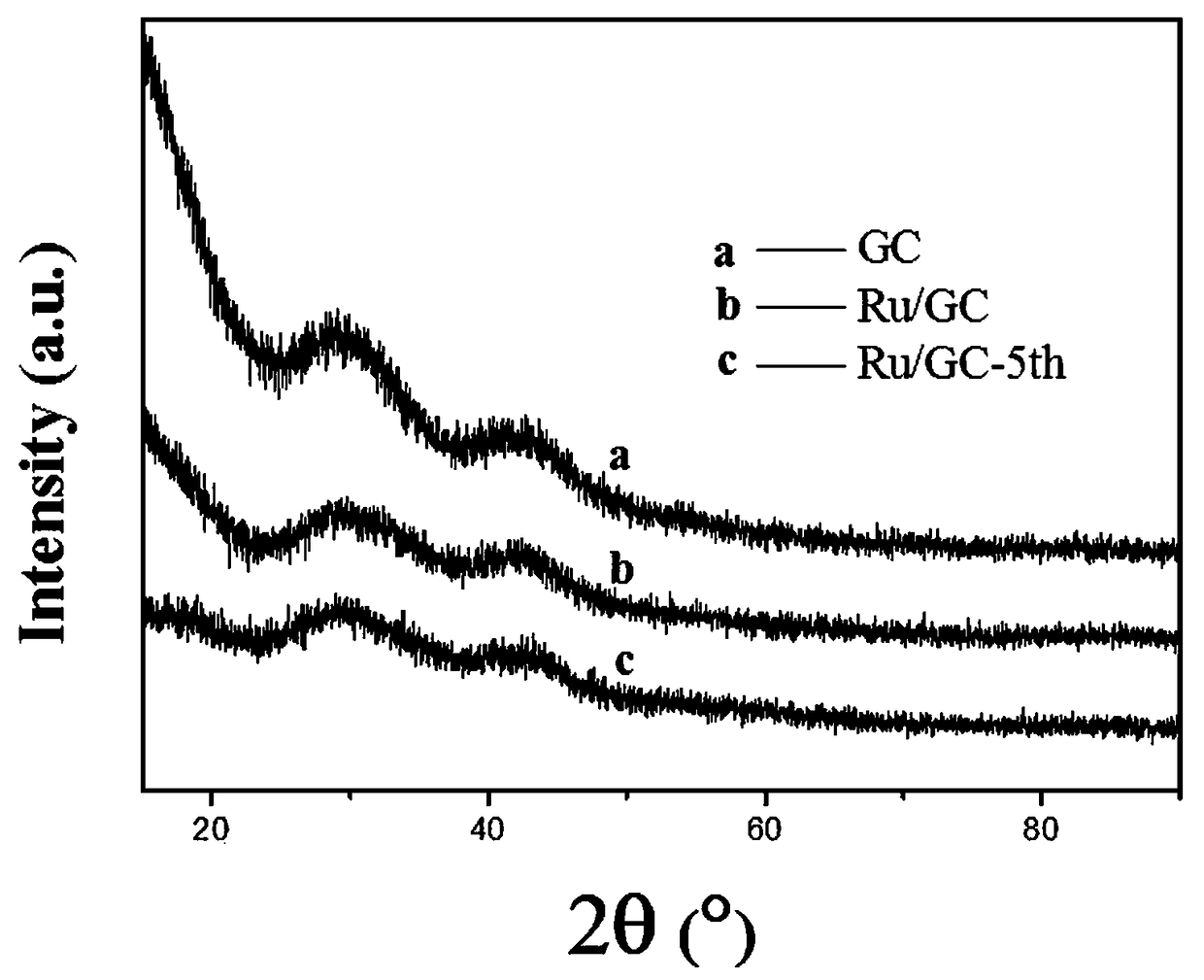

Image

Examples

Embodiment

[0039] A preparation method of a ginkgo leaf-based porous carbon material loaded with ruthenium, the specific steps are as follows:

[0040] Step 1) Low-temperature carbonization of ginkgo leaves. Wash the ginkgo leaves, cut them into 1 cm*1 cm pieces, and dry them. Then, put it into a muffle furnace for low-temperature carbonization at 300 °C for 2 h. Afterwards, the carbonized product is filtered, washed, dried and ground to obtain the ginkgo leaf-based carbon material.

[0041] Step 2) Activation of ginkgo leaf-based carbon material, mix the ginkgo leaf-based carbon material obtained in step 1) with semicarbazide hydrochloride and potassium hydroxide at a mass ratio of 1.0:0.5:3, add 50 ml of deionized water, soak, After drying, put it into a tube furnace filled with nitrogen for calcination at an activation temperature of 800 °C and an activation time of 2 h to obtain a nitrogen-doped modified ginkgo leaf-based carbon material. The product was soaked in 1 M hydrochloric ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com