Using method for tobacco leaf slitting

A technology of tobacco leaf and cutting area, which is applied in the direction of tobacco, application, and treatment of tobacco, so as to achieve good promotion and application value, overcome the bottleneck of raw material shortage, and improve the effect of use value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

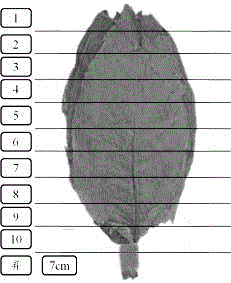

[0012] A method for cutting and using tobacco leaves, comprising the following steps: ① Cutting off the leaf base part of the tobacco leaves (Jixian Zhongyan 100 lower part tobacco) horizontally by 7 cm, and cutting the remaining part horizontally into 10 cutting areas, 10 cutting areas The width is the same, and the 10 cutting areas are numbered sequentially as the 1st-10th cutting areas along the direction from the leaf tip to the leaf base. The nicotine content of the tobacco leaves (HN1-10) in the 10 cutting areas, the nicotine content of the lower tobacco of Jiaxian Zhongyan 100 and the nicotine content of the middle tobacco of Jiaxian Zhongyan 100 are shown in Table 1:

[0013] .

[0014] The nicotine content (2.12%) of the whole tobacco leaf of Jiaxian China Tobacco 100 lower tobacco leaves is lower than that of Jiaxian China Tobacco 100 middle tobacco leaves (2.27%), and the cut HN-1, HN The nicotine content of -2, HN-3, and HN-4 is close to that of Jiaxian China To...

Embodiment 2

[0016] A method for cutting and using tobacco leaves, comprising the following steps: ① cutting the base part of the tobacco leaves (Lushiyun 87 lower part tobacco) horizontally by 7 cm, and cutting the remaining part horizontally into 10 cutting areas, the 10 cutting areas The width is the same, and the 10 cutting areas are sequentially numbered as the 1st to 10th cutting areas along the direction from the leaf tip to the leaf base. The nicotine content of tobacco leaves (HN1-10) in 10 cutting areas, the nicotine content of Lushiyun 87 lower tobacco and the nicotine content of Kunming Yun 87 lower tobacco are shown in Table 2:

[0017] .

[0018] The nicotine content (2.23%) of the lower tobacco leaf of Lushiyun 87 was lower than that of the whole leaf (2.37%) of the lower tobacco leaf of Kunming Yun87. HN-1, HN- 2. The nicotine content of HN-3 and HN-4 is close to that of Kunming Yun 87 Lower Tobacco. The tobacco leaves from the 1st to 4th cutting areas are combined into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com