Patents

Literature

33results about How to "Slow dehydration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

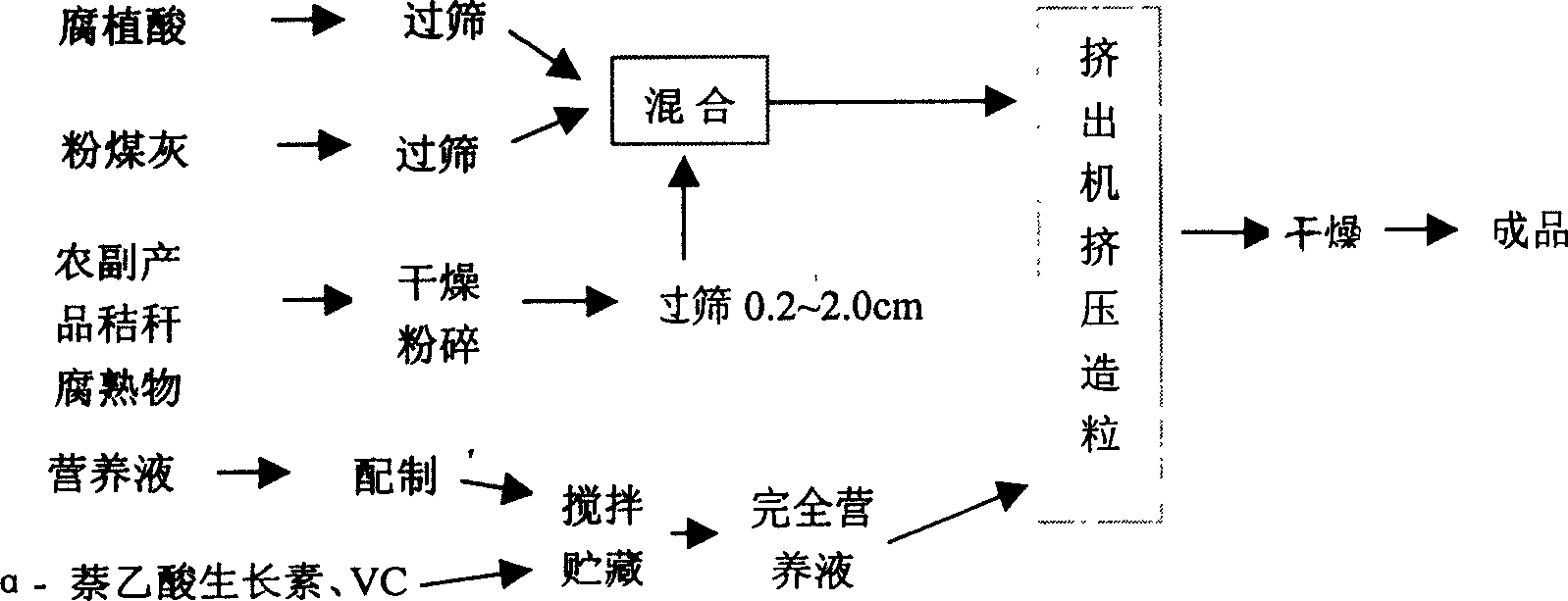

Nutrient medium for plant ecological cultivation, and its prepn. method

InactiveCN1559180AReduce nitrate levelsImprove food safetyCultivating equipmentsSoilless cultivationWater savingCoal

A nutritive medium for ecologically culturing plant is prepared from powdered coal ash, strew and stalk, fermented plants, and other nutritive, water-saving and rooting components. It can increase survival rate and yield of crops.

Owner:ZHEJIANG UNIV

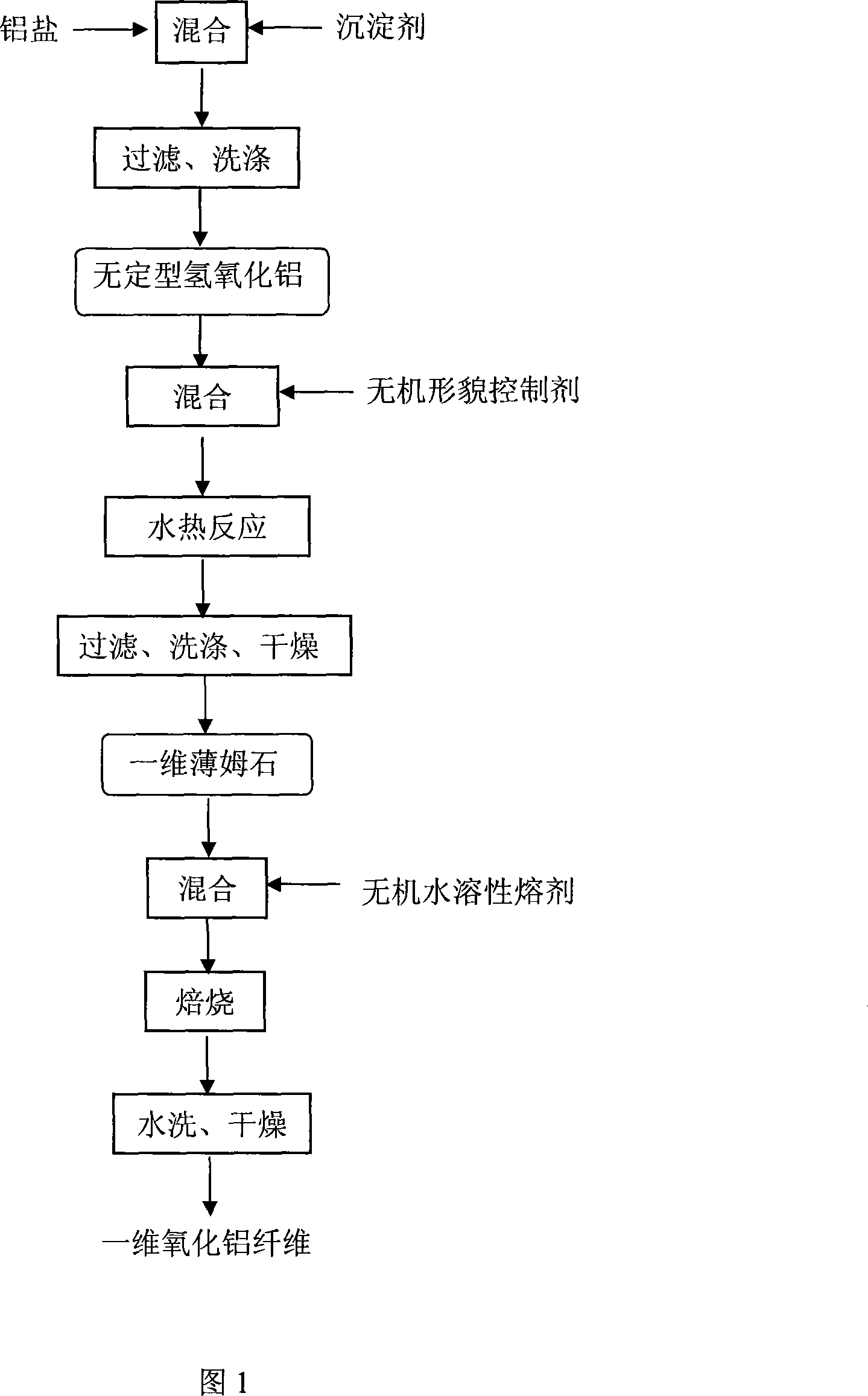

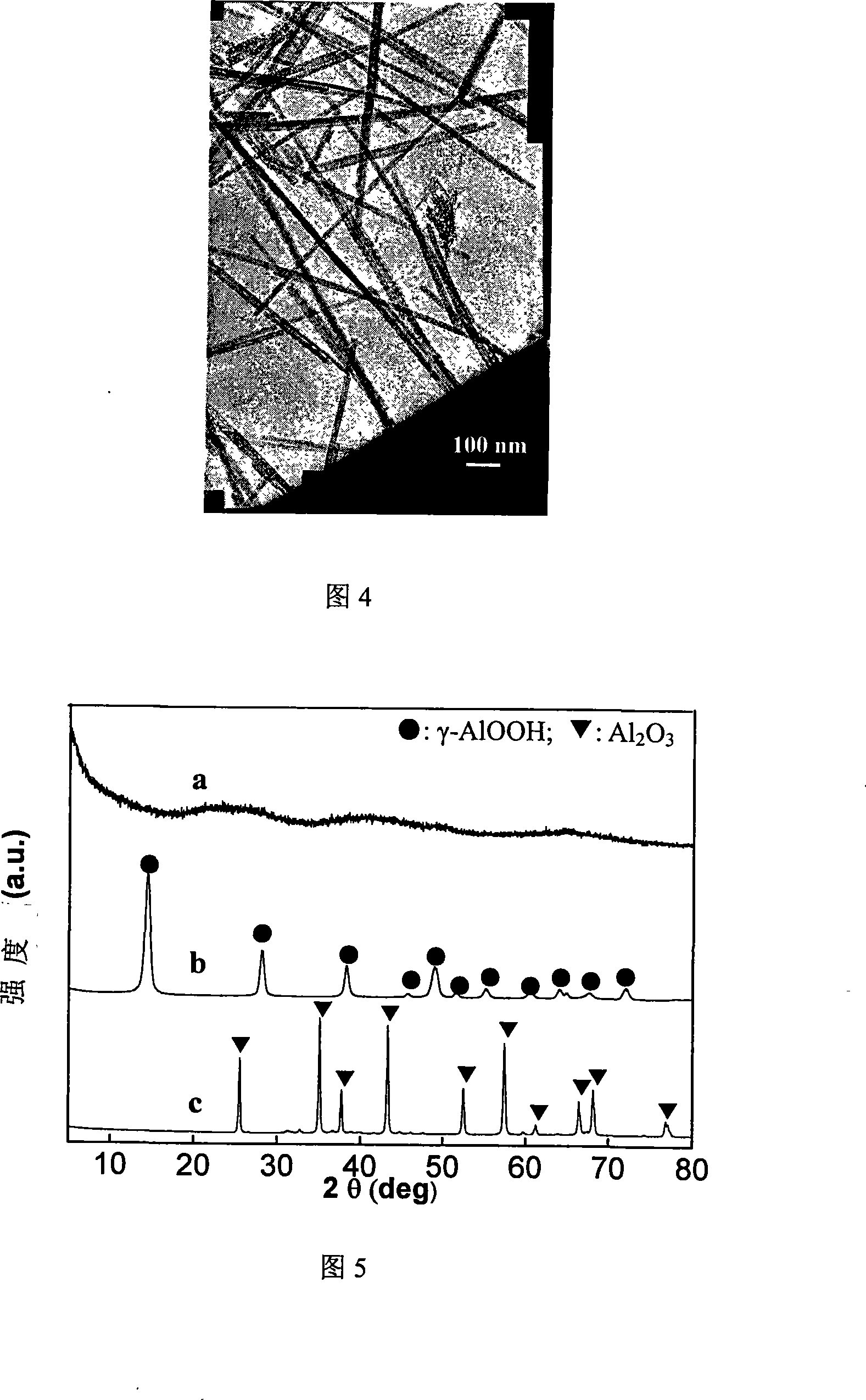

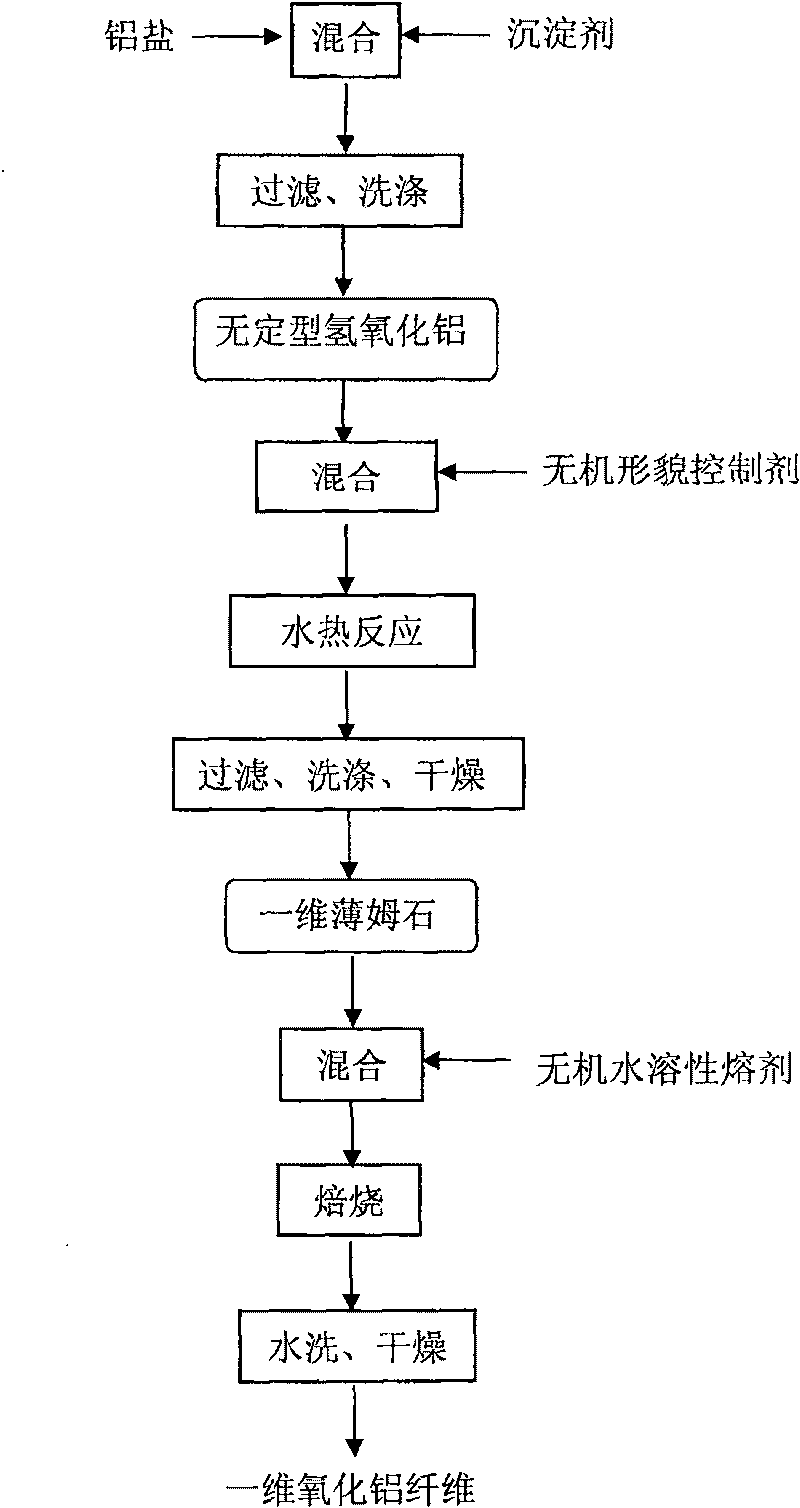

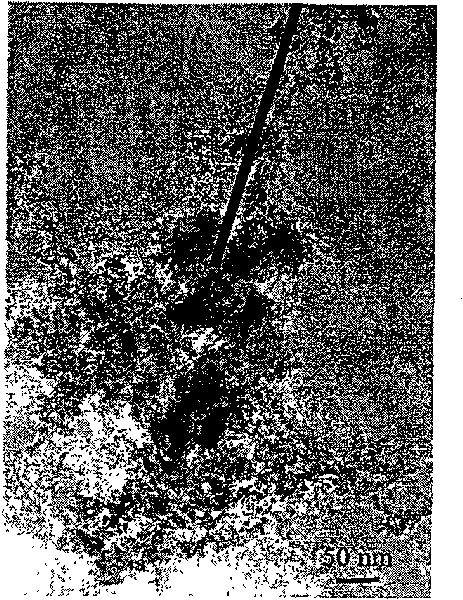

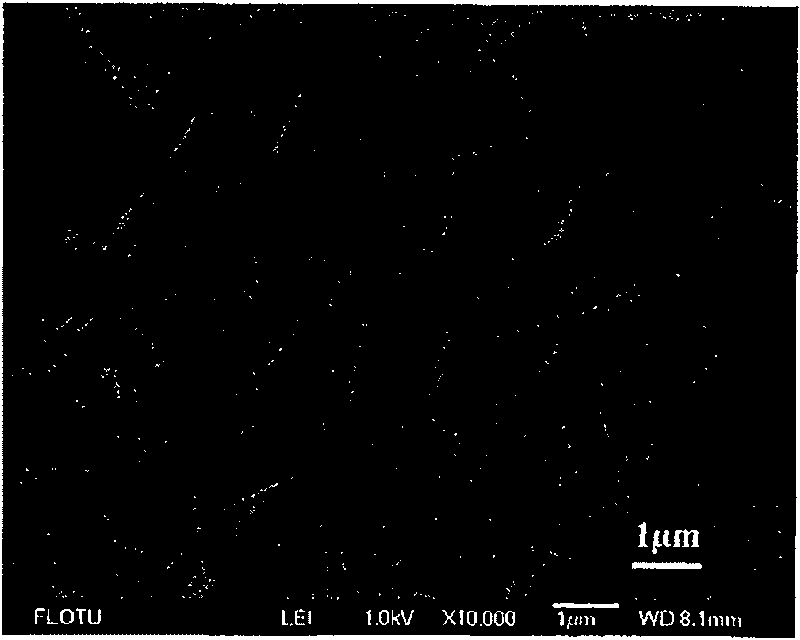

Method for preparing one-dimensional aluminum oxide fibre by hydrothermal-flux technique

InactiveCN101182024APromote crystallizationIncrease added valueNanostructure manufactureAluminium oxide/hydroxide preparationFiberAluminium hydroxide

The invention discloses a method for preparing one-dimensional alumina fiber by a hydrothermal-flux process, which belongs to the technical field of preparation of inorganic chemical materials. In the present invention, inorganic water-soluble aluminum salt is used as raw material, and inorganic alkali or inorganic acid is used as precipitating agent. Firstly, amorphous aluminum hydroxide precipitate is prepared by a normal temperature synthesis method, and then added to an aqueous solution containing an inorganic morphology control agent for hydrothermal reaction. , to obtain a one-dimensional boehmite (γ-AlOOH) intermediate product; then mix γ-AlOOH with flux, and after multi-stage roasting, it can be obtained with a diameter of 10-100nm, a length of 0.5-10μm, and an aspect ratio of 50-200. A one-dimensional alumina fiber with regular appearance and good crystallization. The invention has the advantages of simple process, low cost, high added value and easy industrial popularization. The one-dimensional alumina fiber prepared by the invention has superior performance and high added value, and can be used as a reinforcing material in industries such as aluminum alloy, ceramics, plastics, and rubber.

Owner:TSINGHUA UNIV

Method for drying honeysuckles

InactiveCN103822442ASimple production processLow costDrying using combination processesDrying solid materials with heatComposite materialProcess engineering

The invention discloses a method for drying honeysuckles. The method includes placing screened fresh honeysuckles into color-protecting solution; laying the honeysuckles on stainless steel screen cloth after the color-protecting solution on the honeysuckles is drained, and placing the stainless steel screen cloth in a drying chamber of a heat pump drying machine; setting the temperature of the drying chamber at 40-60 DEG C, setting an air speed of the drying chamber at 1-2.5m / s and setting the concentration of oxygen in the drying chamber at 5-21%; filling the drying chamber with nitrogen for 3-5 minutes at intervals of 20-30 minutes in drying procedures, keeping the required concentration of the oxygen in the drying chamber unchanged, and drying the honeysuckles for 6-10 hours to obtain the honeysuckles which are dried by the aid of heat pumps; placing the screen cloth with the honeysuckles into a microwave generator after the honeysuckles are dried by the aid of the heat pumps, and drying the honeysuckles by the aid of microwaves until the moisture contents of the honeysuckles are lower than or equal to 12%; spreading the honeysuckles in cool, clean and ventilation positions to temper the honeysuckles; loading the honeysuckles in compound zip-lock bags, and filling the insides of the bags with nitrogen so that the concentration of oxygen in each bag is lower than or equal to 5%. The drying chamber of the heat pump drying machine is preheated for at least 30 minutes before the stainless steel screen cloth is placed in the drying chamber. The method has the advantages that a manufacturing process is simple, the cost is low, and the quality of products are stable; a brightness value L of the honeysuckles manufactured by the method is larger than 60, the total phenol content of the honeysuckles is higher than 0.5%, a chlorogenic acid loss rate is lower than 20%, and the method has obvious merits, an important application prospect and high popularization utilization value.

Owner:HENAN UNIV OF SCI & TECH

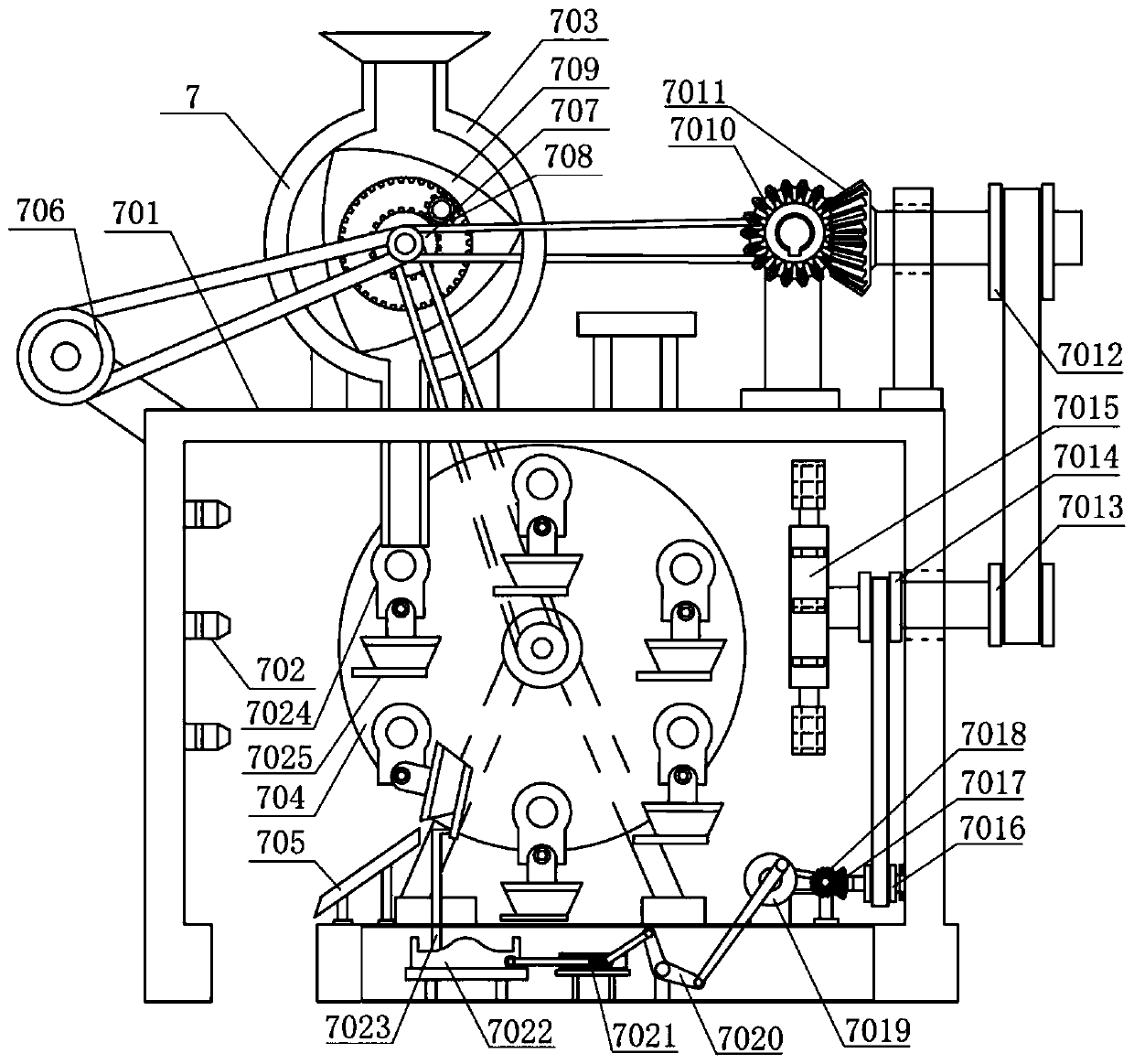

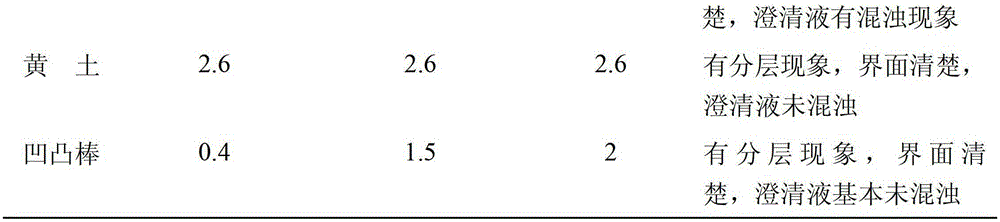

Composite gel for preventing spontaneous combustion of coal

InactiveCN102173722AOvercoming the disadvantage of releasing ammonia gasNo pollutionDust removalFire preventionSodium bicarbonateSpontaneous combustion

The invention discloses a composite gel for preventing spontaneous combustion of coal, which comprises the following ingredients in percentage by weight: 5 to 8 percent of base material, 2 to 5 percent of accelerating agent, 6 to 9 percent of aggregate material, 0.5 to 3 of water-retaining agent and the balance of water. The base material is water glass, the accelerating agent is sodium bicarbonate, the aggregate material is diatomite, and the water-retaining agent is salt-resistant highly-water-absorbent resin. The salt-resistant highly-water-absorbent resin is made by aqueous solution polymerization or reverse-phase suspension polymerization, and has a water absorbency of 1250 to 1355 g<g> and a salt absorbency of 100 to 120 g<g>. The produced gel is excellent in leak stoppage, oxygen insulation, temperature drop and retardancy, has good fluidity and strong moisture-retaining property and can slow water loss. The gel products with different gelling time are made by adjusting the proportions. The gel is convenient and flexible in use, has strong adaptability, and can be widely applied to various high-risk and self-combustible coal areas.

Owner:CHINA UNIV OF MINING & TECH (BEIJING) +2

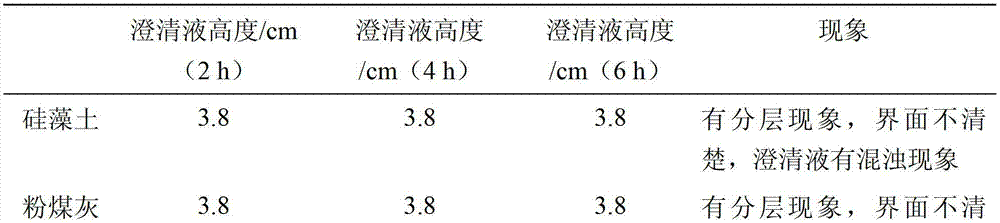

Mine loess composite gel fire preventing and extinguishing material and preparation method of material

The invention claims a mine loess composite gel fire preventing and extinguishing material and a preparation method of the material. The mine loess composite gel fire preventing and extinguishing material comprises a base material, a coagulation accelerator and an aggregate, wherein the base material is sodium silicate; the coagulation accelerator adopts polyacrylamide; and the aggregate is loess. The preparation method disclosed by the invention comprises the following steps of: firstly, mixing the base material and the coagulation accelerator and mixing the aggregate and water, and subsequently, mixing and stirring two slurry solutions to acquire the product. The mine loess composite gel fire preventing and extinguishing material is low in cost, great in viscosity and good in stability.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

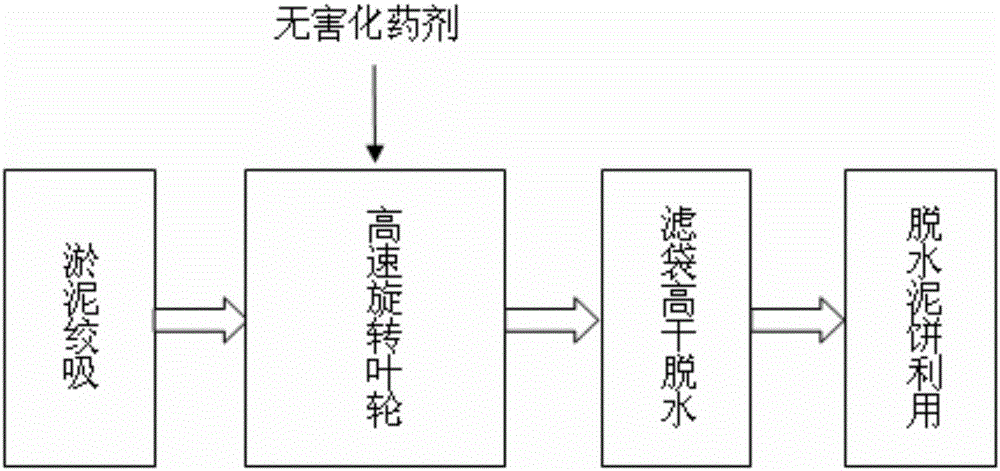

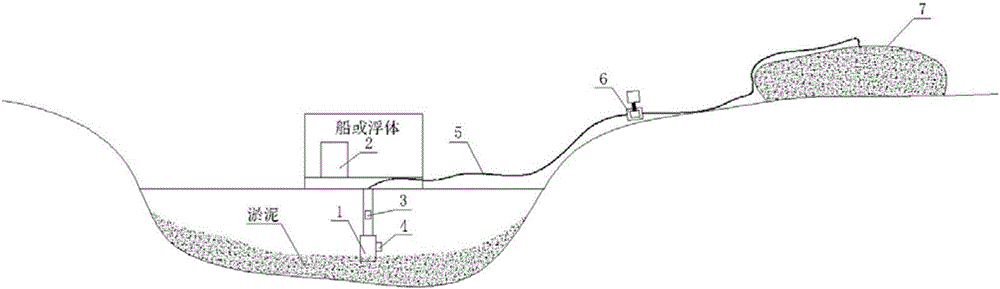

Water body silt cleaning and harmless treatment and deposal system

InactiveCN106186636AReasonable control of suction depthReduce pollutionSludge treatment by de-watering/drying/thickeningMechanical machines/dredgersImpellerEnvironmental engineering

The invention provides a water body silt cleaning and harmless treatment and deposal system, which comprises a silt suction and conveying device, a harmless treatment device and a dewatering treatment device in sequential connection through a silt conveying pipeline, wherein the silt suction and conveying device comprises the following parts including a silt suction unit, a first sensor, a second sensor and an intelligent control unit; the harmless treatment device is a rotating impeller driven by a driving motor; the dewatering treatment device is a filtering bag. The invention further provides a water body silt cleaning and harmless treatment and deposal method. The water body silt cleaning and harmless treatment and deposal system provided by the invention is combined with the process; the pollution on the peripheral water body in the suction process can be reduced; the dispersion degree of the silt is improved; good mixing of silt and added chemicals is realized; the treated mud cake has high dryness, can be used for reinforcing embankment and can also be conveyed out to be used for as filling soil or greening soil.

Owner:徐吉浣 +1

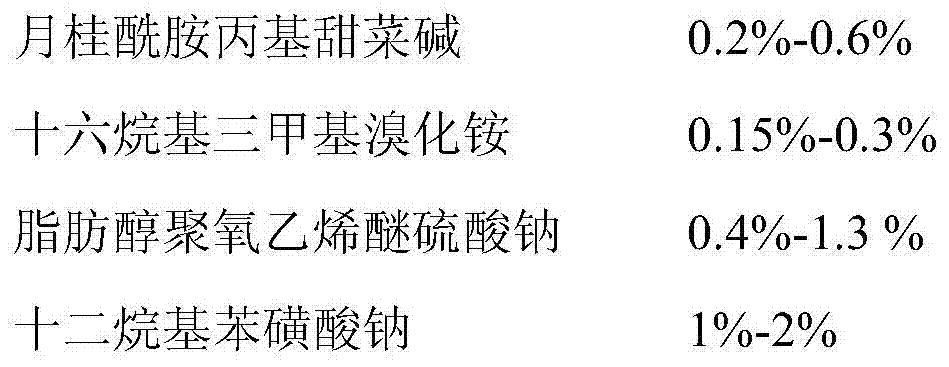

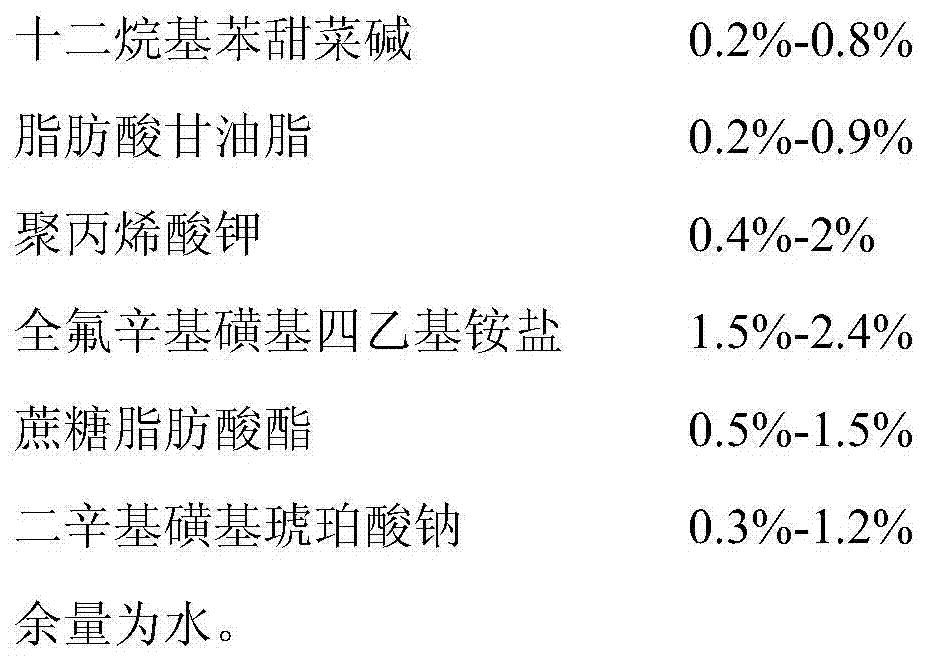

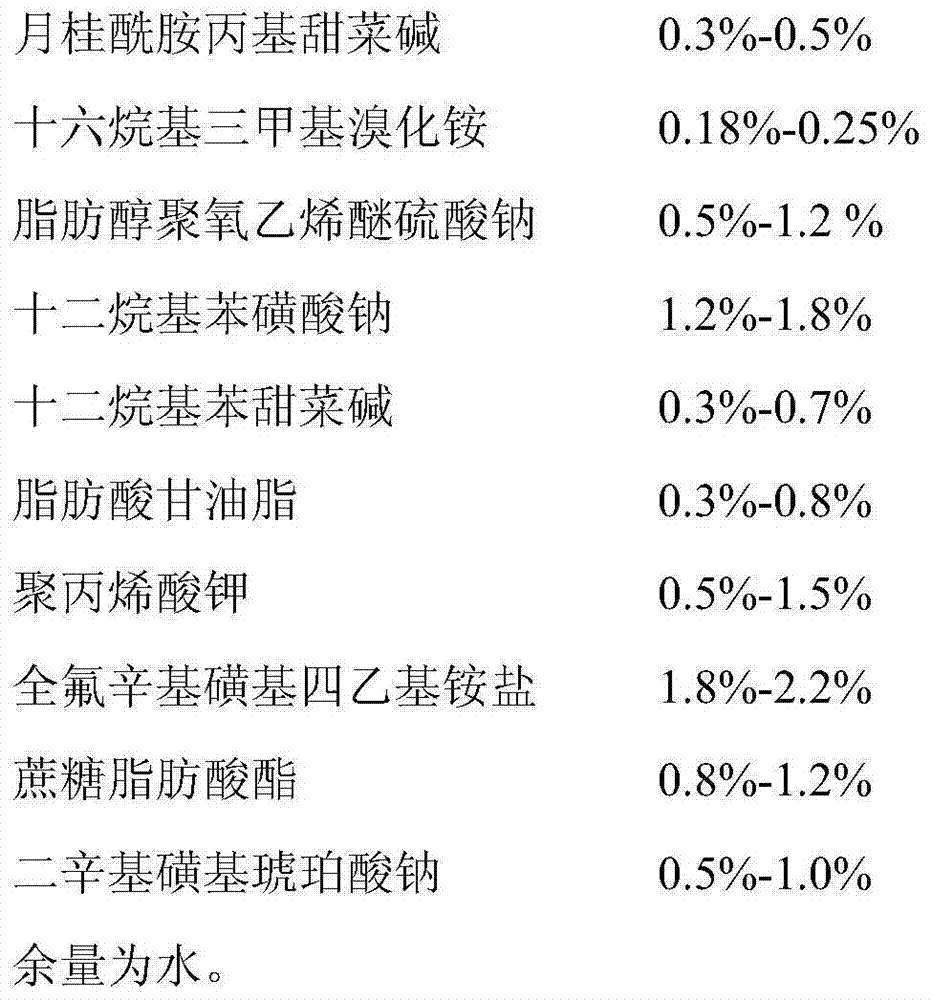

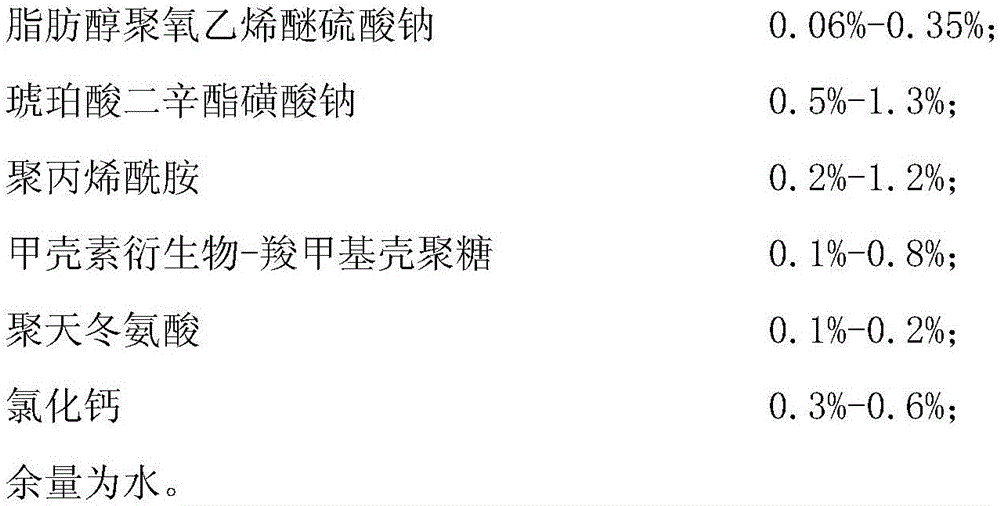

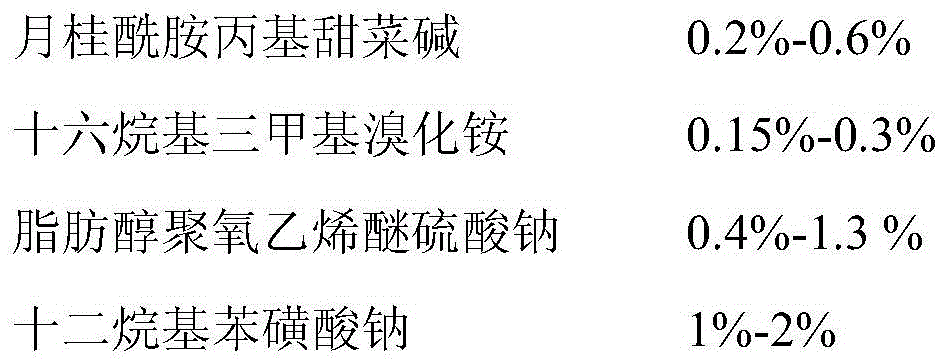

Foam producing agent for wet-type dust collection

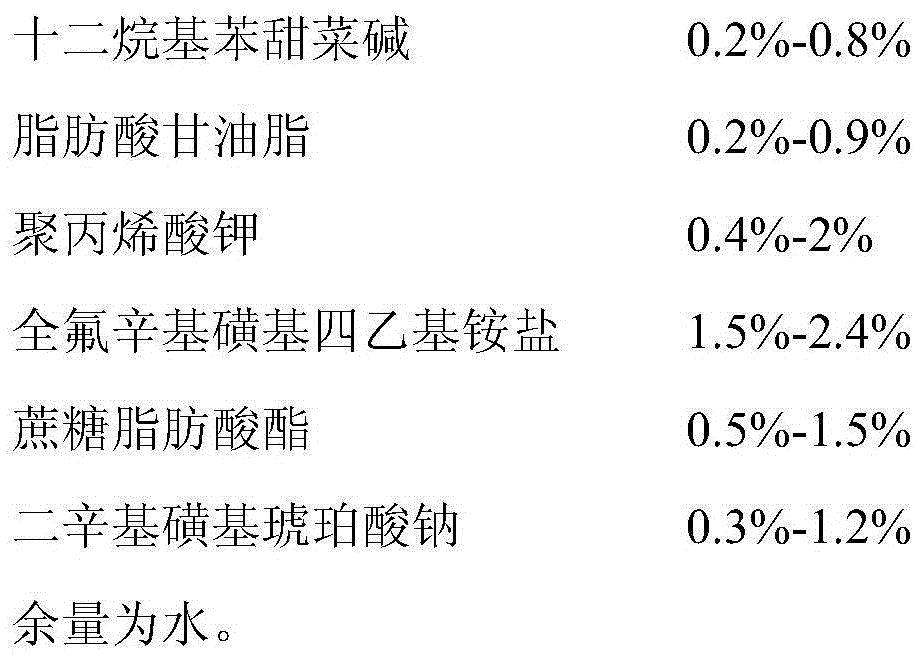

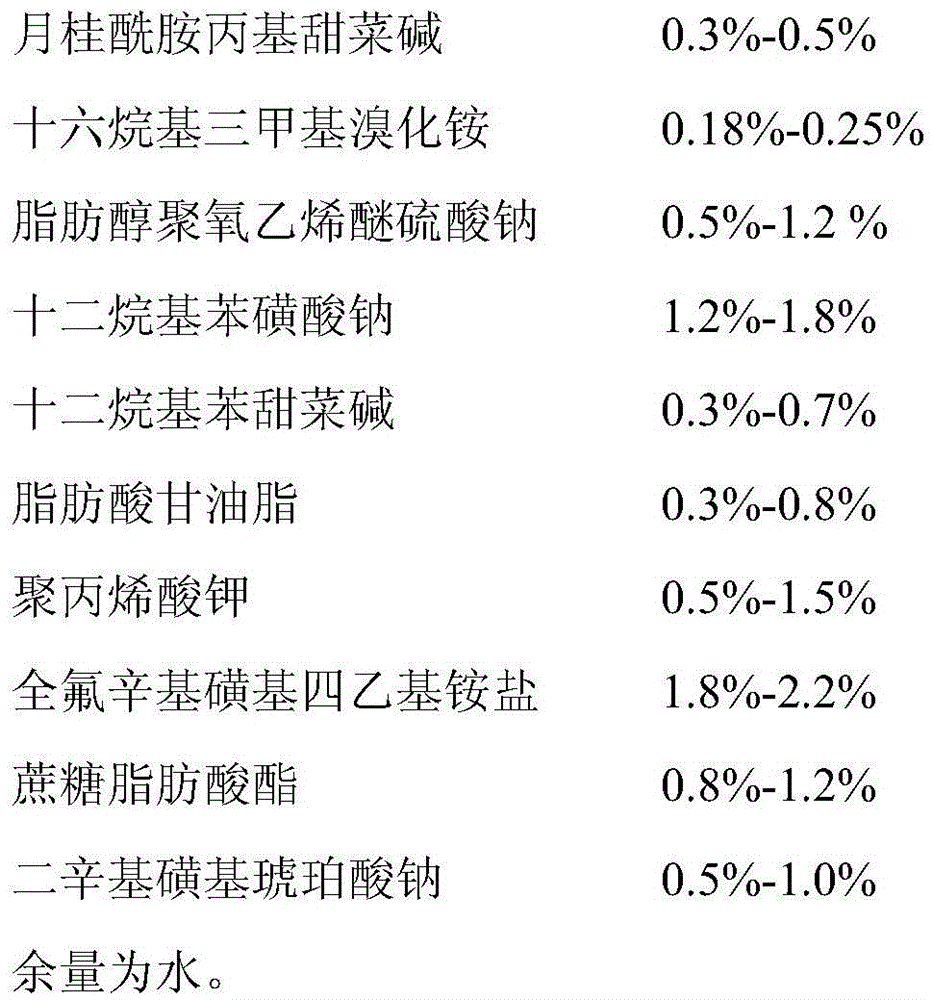

The invention discloses a foam producing agent for wet-type dust collection. According to the weight percentage, the foam producing agent for the wet-type dust collection comprises: 0.2%-6% of lauramide propyl glycine betaine, 0.15%-0.3% of hexadecyl tri-methyl ammonium bromide, 0.4%-1.3% of fatty alcohol-polyoxyethylene ether sodium sulfate, 1%-2% of sodium dodecyl benzene sulfonate, 0.2%-0.8% of dodecyl benzene glycine betaine, 0.2%-0.9% of fatty acid glycerolipid, 0.4%-2% of potassium polyacrylate, 1.5%-2.4% of perfluor octyl sulfo tetraethyl ammonium salt, 0.5%-1.5% of sucrose fatty acid ester, 0.3%-1.2% of diocytyl sulfo sodium succinate, and the balance is water. The foam producing agent for the wet-type dust collection is capable of cohering the dusts on the ground for a long time, avoiding the dusts from flying along with the wind because of the drying ground, and performing the collecting function to a duster for a long time. The foams produced by the foam producing agent for the wet-type dust collection have good biological degradability, and both the environmental protection coefficient and the safety coefficient are high.

Owner:SHANDONG UNIV OF SCI & TECH

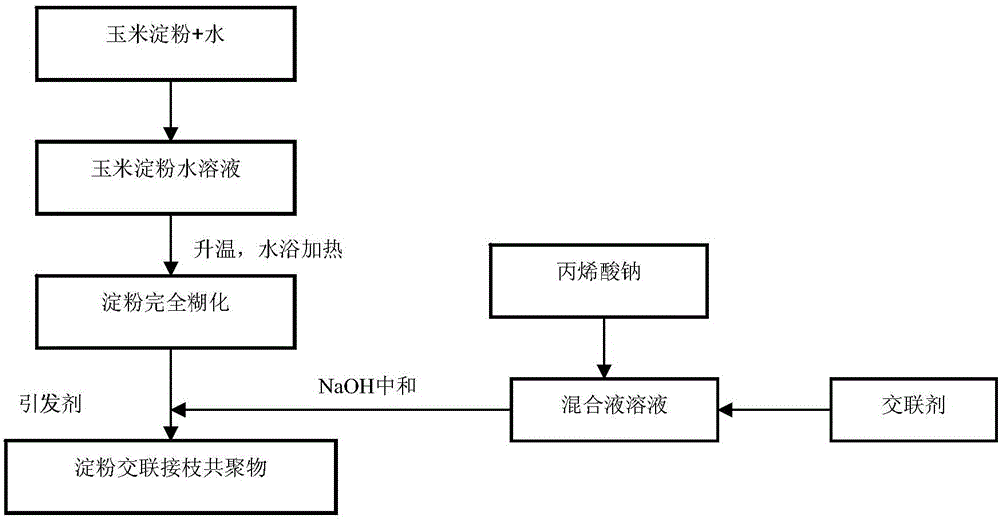

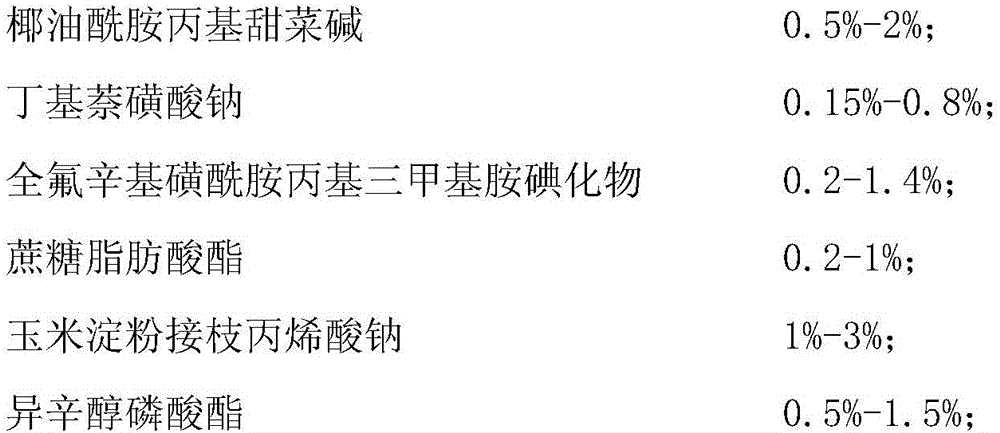

Permeability-increasing and coagulation-accelerating wetting agent for wet-type dust control

ActiveCN105778867AReduce surface tensionIncrease surface tensionOther chemical processesDust removalSucrosePhosphate

The invention discloses a permeability-increasing and coagulation-accelerating wetting agent for wet-type dust control. The permeability-increasing and coagulation-accelerating wetting agent comprises 0.5%-2% of cocamidopropyl betaine, 0.15%-0.8% of butylnaphthalenesulfonic acid sodium salt, 0.2%-1% of trimethyl-1-propanaminium iodide, 0.2%-1% of sucrose fatty acid ester, 1%-3% of corn starch grafting sodium acrylate, 0.5%-1.5% of isooctanol phosphate, 0.06%-0.35% of sodium alcohol ether sulphate, 0.5%-1.3% of sodium diethylhexyl sulfosuccinate, 0.2%-1.2% of polyacrylamide, 0.1%-0.8% of chitin derivative-carboxymethyl chitosan, 0.1%-0.2% of polyaspartic acid, 0.3%-0.6% of calcium chloride and the balance water. The ermeability-increasing and coagulation-accelerating wetting agent for wet-type dust control has the advantages that wetting ability of water for coal is enhanced and water molecules can wrap coal dust particles quickly, so that coagulation and falling of the coal dust particles are facilitated.

Owner:SHANDONG UNIV OF SCI & TECH

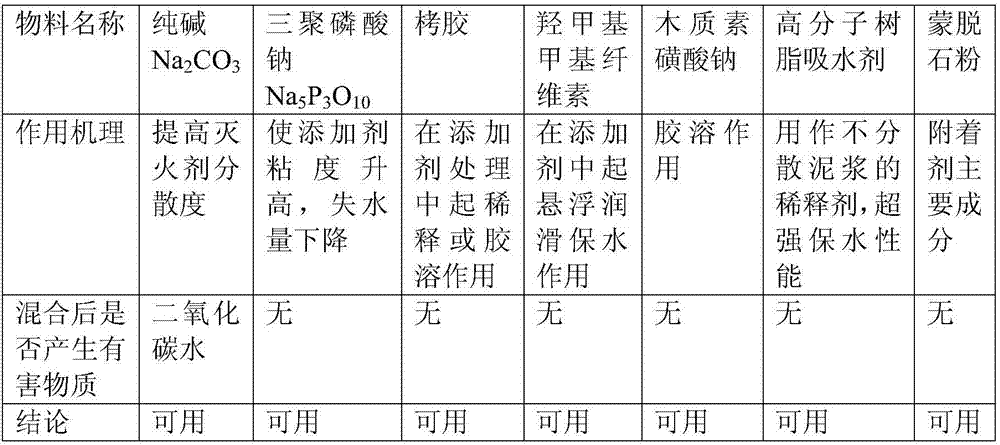

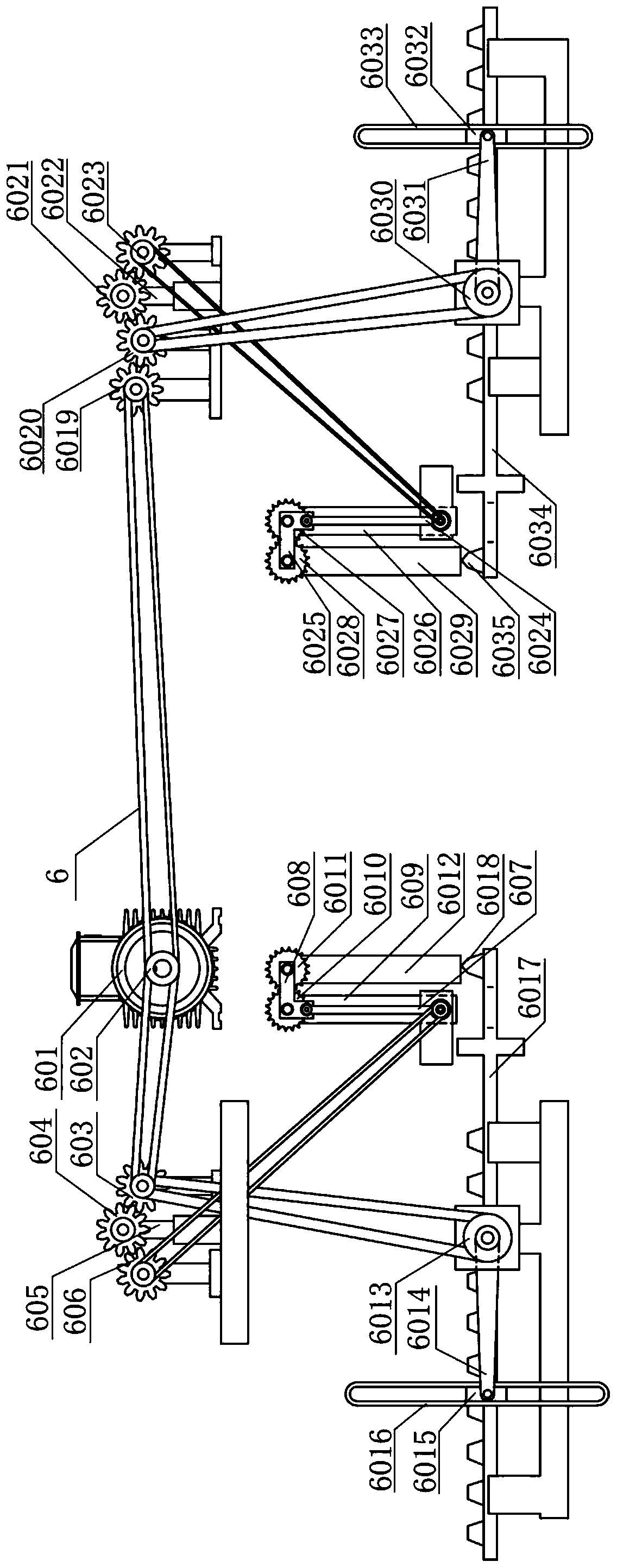

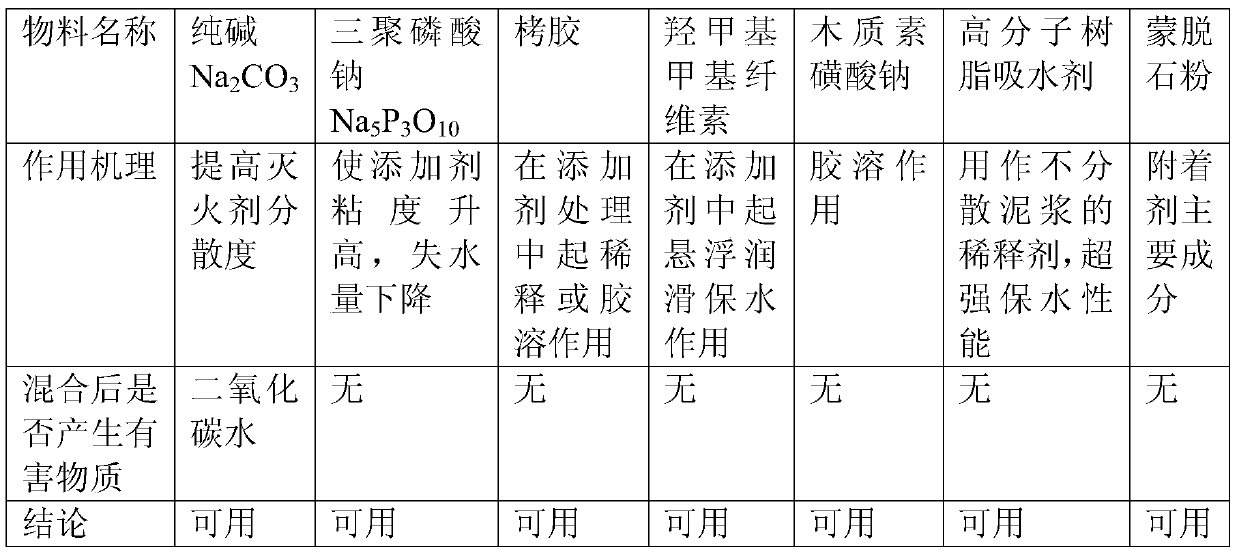

Mining fire extinguishing material additive and application thereof

ActiveCN107308583ALow costNo pollution in the processDust removalFire preventionSuper absorbentSuspending Agents

The invention discloses a mining fire extinguishing material additive and application of the mining fire extinguishing material additive. The mining fire extinguishing material additive is prepared from, by weight, 40-80 parts of silicate materials, 0.1-5 parts of tackifier, 1-10 parts of dispersing agent, 5-20 parts of surfactant, 1-10 parts of suspending agent, 1-10 parts of super absorbent polymer and 1-10 parts of diluter. The mining fire extinguishing material additive has the advantages of being prepared from the easy-to-obtain raw materials, and being low in cost, easy to implement, good in gelatination effect, high in water retaining capacity, low in water loss speed, applicable to being added into coal ash, yellow mud, white mud and other underground coal mine filling grouting materials and excellent in fire preventing and extinguishing performance.

Owner:北票天宝耐火材料有限公司

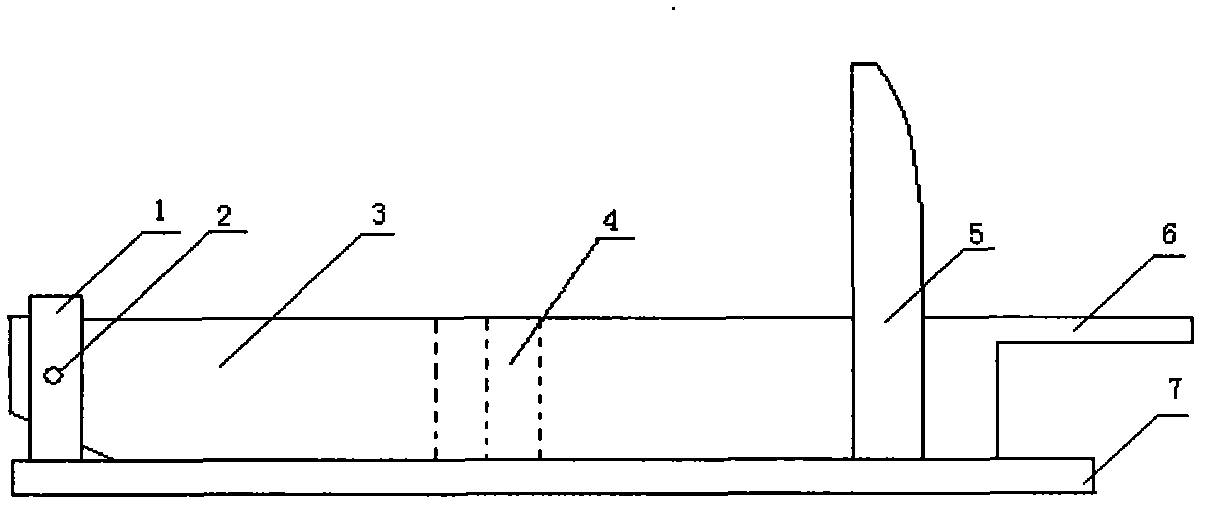

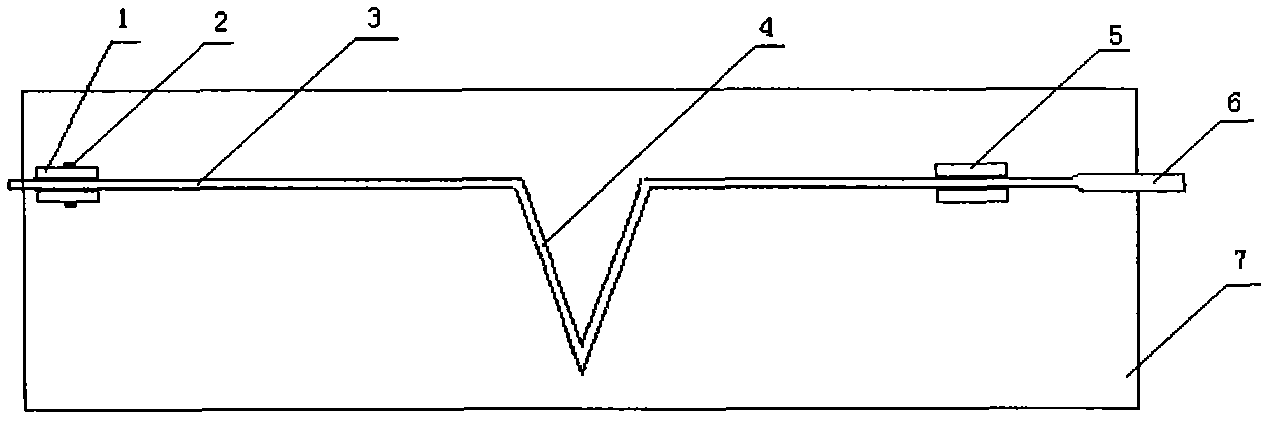

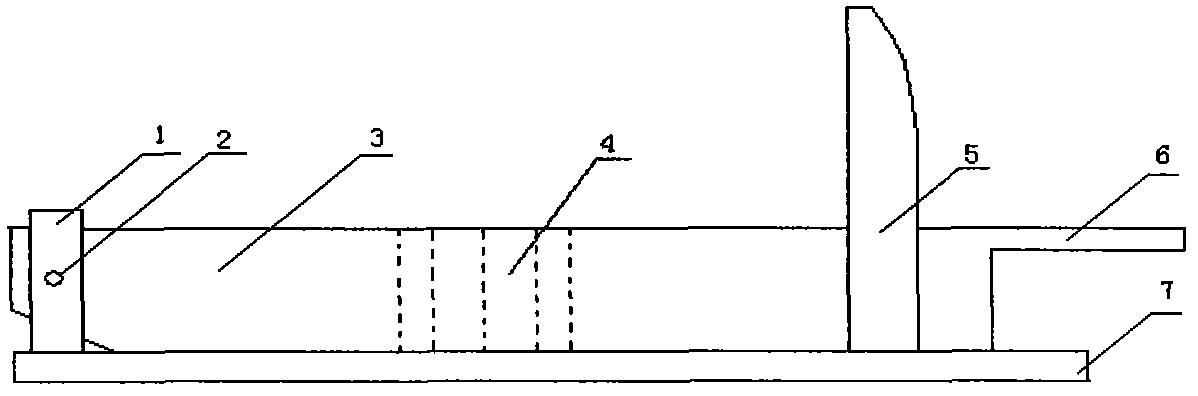

Tobacco leaf modulating and stalk-removing method and cutter

InactiveCN103564640ASlow dehydrationModulation consumes a lot of energyTobacco treatmentEconomic benefitsEngineering

The invention provides a tobacco leaf modulating and stalk-removing method and a cutter. Before or in a tobacco leaf modulating process, a common cutter, a special cutter or a professional machine isused for removing a part of the stalk of each tobacco leaf, wherein a leaf base or the tobacco stalk with 1 / 5 to 1 / 2 of the length of each tobacco leaf is cut off. The cutter comprises a cutter holder, a cutter head fixing frame, a cutter shaft, a cutter body, a stabilizing frame and a cutter handle, wherein the cutter body is hinged to the cutter shaft through the cutter head fixing frame and then is arranged on the cutter holder; the middle part of the cutter body is bent in a V or M shape, and a cutter slot matched with the cutter body is formed in the cutter holder. The tobacco leaf modulating and stalk-removing method disclosed by the invention is applied to a flue-cured tobacco leaf piece dense baking process; the temperature of a stalk drying period can be reduced, the baking time is shortened, and 30-50% of energy is saved; the operation is simple and convenient, the efficiency is high, the disadvantages of a manual stalk removing process are overcome, and the popularization inproduction is easy; the quality of modulated tobacco leaves is improved, the stalk-removing and modulation of tobacco leaves can be realized in large scale, and excellent energy saving, environment-friendliness and economic benefits are achieved.

Owner:朱大恒

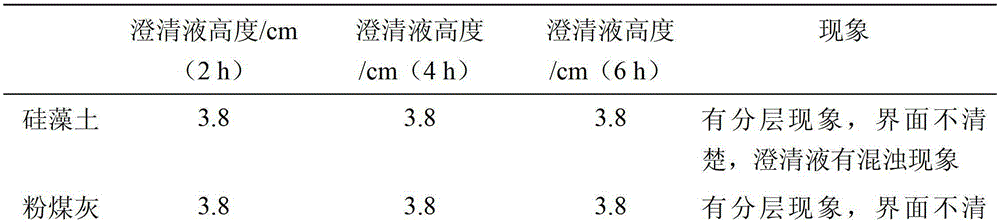

Extinguishing material for coal mine, and production method thereof

The invention relates to extinguishing material for coal mine and a production method thereof and belongs to the field of coal mine materials for fire preventing and extinguishing. The extinguishing material is made by mixing well 5-15wt% of attapulgite, 1-5wt% of salt-resistant super-absorbent polymer and water. Preparation of the salt-resistant super-absorbent polymer includes: adding 3 parts of acrylic acid into an ice bath, neutralizing with sodium hydroxide, adding 4 parts of acrylamide to from a monomer, and sequentially adding potassium peroxodisulfate accounting for 0.25% of the total weight of the monomer and N, N-methylene bisacrylamide accounting for 0.25% of the total weight of the monomer; heating a water bath to 70 DEG C, allowing for reaction for 7h, and filtering and drying the cooled reaction product. Aggregate using the attapulgite as colloid is fine in suspendability and large in specific area, the obtained colloid is remarkably uniform and long in shelf life.

Owner:BEIJING UNIV OF TECH

Plant tissue culture support

InactiveCN105993961AGrow vigorouslyHigh transplant survival ratePlant tissue cultureHorticulture methodsCulture mediumsPollution

The invention belongs to the technical field of biology, and particularly relates to a plant tissue culture support. The support comprises dry sphagnum and de-ionized water, wherein the volume ratio of the dry sphagnum to the de-ionized water is (0.5-1):1. Compared with the prior art, the plant tissue culture support has the beneficial effects that the plant tissue culture support is easy to operate and low in tissue culture cost; energy resources are saved; the working time is shortened, the labor intensity is reduced, the inoculation efficiency is improved, and the pollution probability is reduced; an explant grows robustly, and is high in transplantation survival rate; good fixing effects are achieved; the air permeability is high; a culture medium is long in service cycle; a tissue culture environment can more meet physiological requirements of a plant.

Owner:DALIAN UNIV

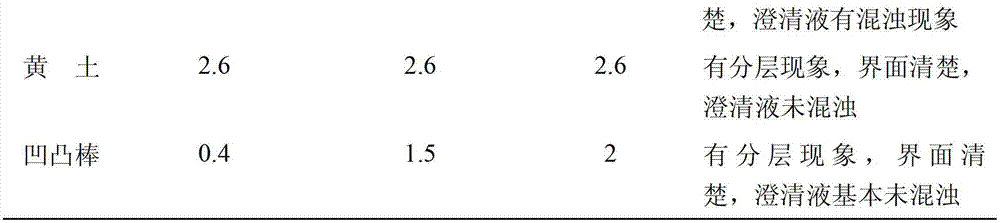

Quasi-gel valve controlled lead acid accumulator

InactiveCN101399365ASlow dehydrationDehydration stableFinal product manufactureLead-acid accumulators constructionEngineeringColloid

The invention discloses a quasi-colloid valve-regulated lead acid storage battery. The storage battery comprises a battery jar and a battery cover arranged on the battery jar, a positive plate and a negative plate are arranged in the battery jar, an AGM separator is arranged between the positive plate and the negative plate, and a colloidal electrolyte protective layer is arranged above the positive plate, the negative plate and the AGM separator in the battery jar. The quasi-colloid valve-regulated lead-acid storage battery has the advantages of slow dehydration, relatively stable electrolyte, uneasy delamination, comparatively even grid corrosion and long service life.

Owner:浙江永达电力实业股份有限公司

Skincare emulsion

InactiveCN103040719AAnti-agingImprove immunityCosmetic preparationsToilet preparationsIsostearyl alcoholGlycerol

The invention belongs to the field of cosmetic, and relates to a skincare emulsion. The skincare emulsion is characterized by comprising the following components by weight part based on 100 weight parts: 4-6 of Vaseline, 4-6 of distearyl dimethyl ammonium chloride, 0.4-0.6 of amino-acid germanium oxide, 3-5 of white fungus extract, 0.5-2 of cetyl alcohol, 0.5-2 of isostearic alcohol, 0.02-0.08 of propylparaben, 0.1-0.2 of essence, 3-5 of glycerin, 0.1-0.3 of titanium dioxide, 1-3 of isopropyl palmitate, 0.05-0.15 of isopropyl palmitate and the balance of deionized water; and the skincare emulsion is an emulsion. The skincare emulsion has the advantages that skin aging is slow, skin immunity is enhanced, skin water loss is slow and the skin is lustrous and tender after the skincare emulsion is used; the skincare emulsion is not oily to give good feeling to users; and the production of the skincare emulsion is simple.

Owner:龚利芬

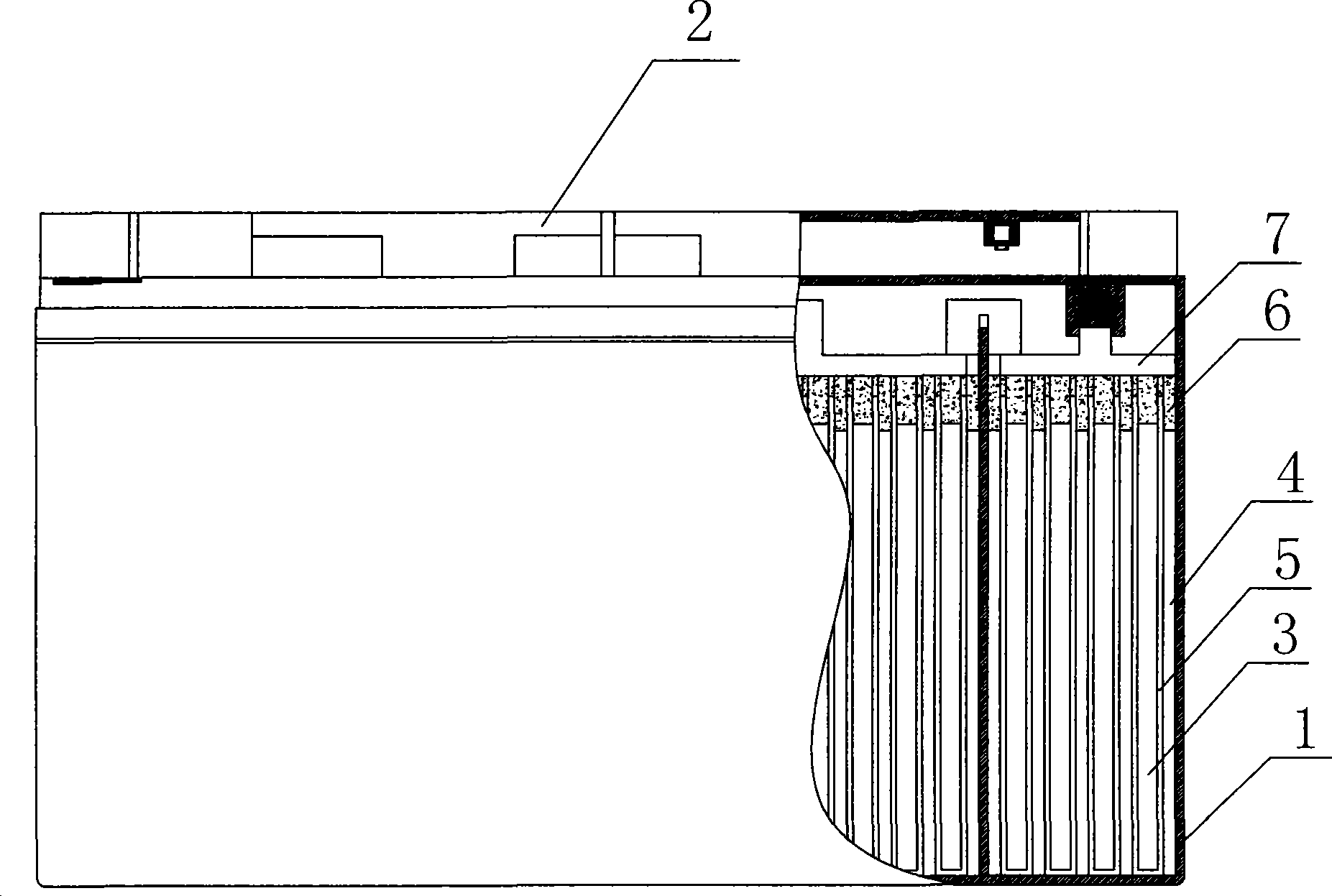

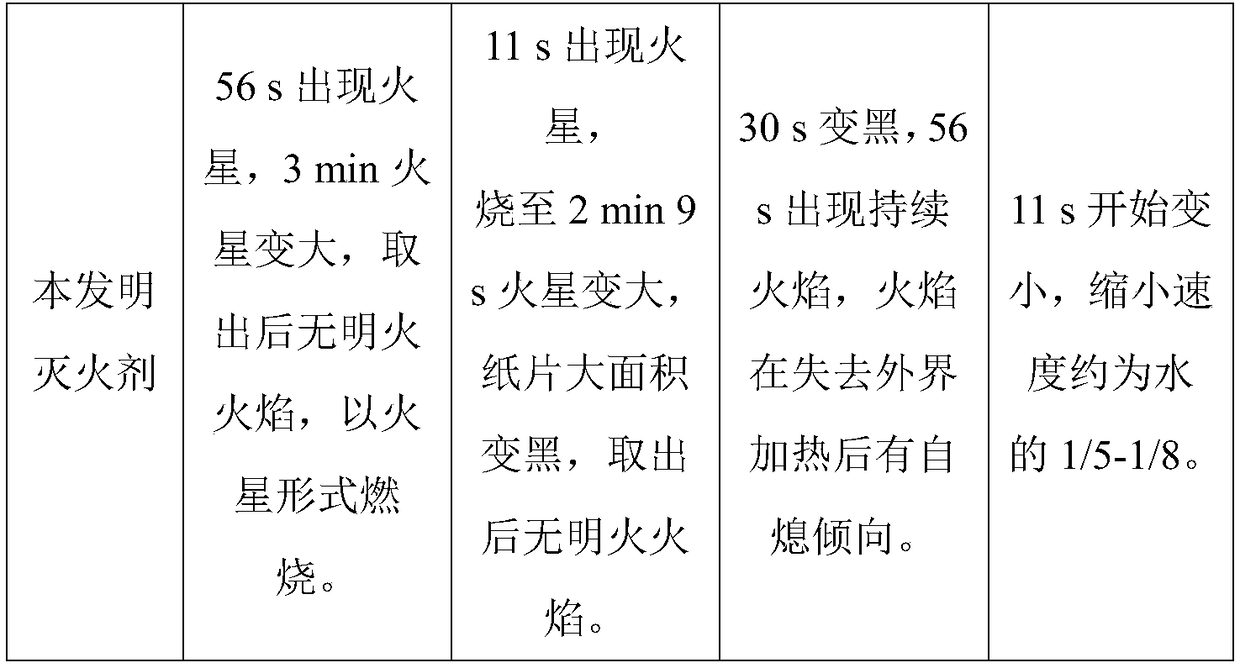

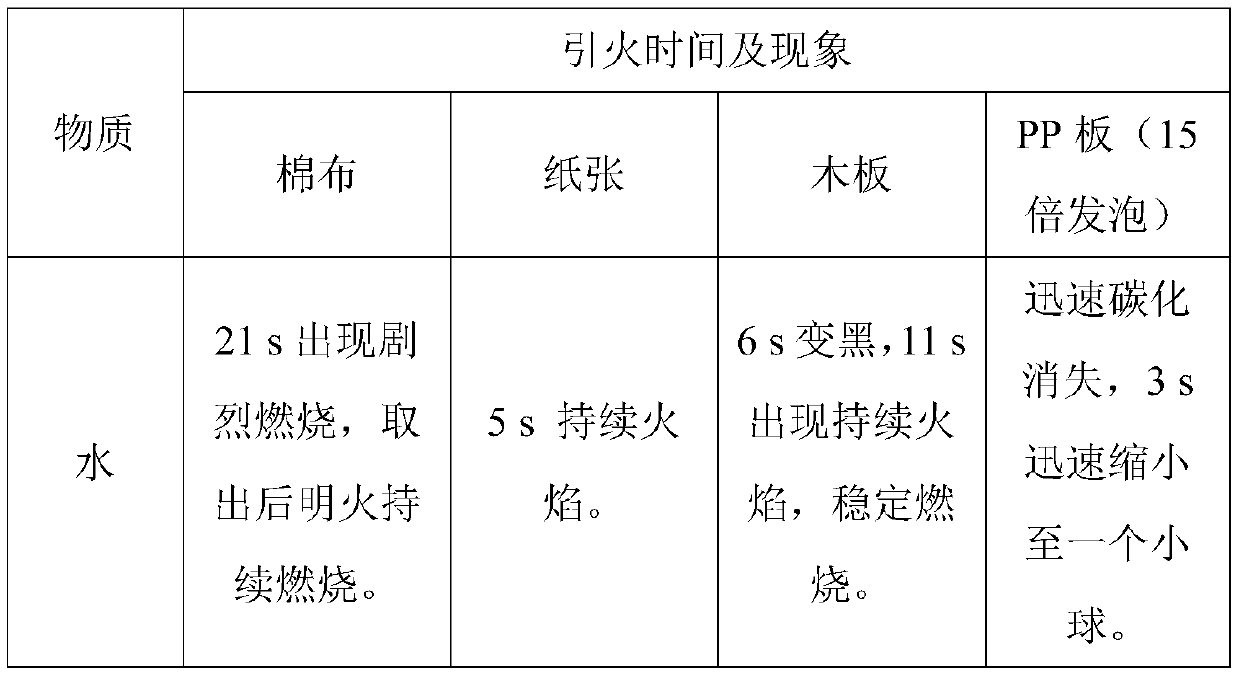

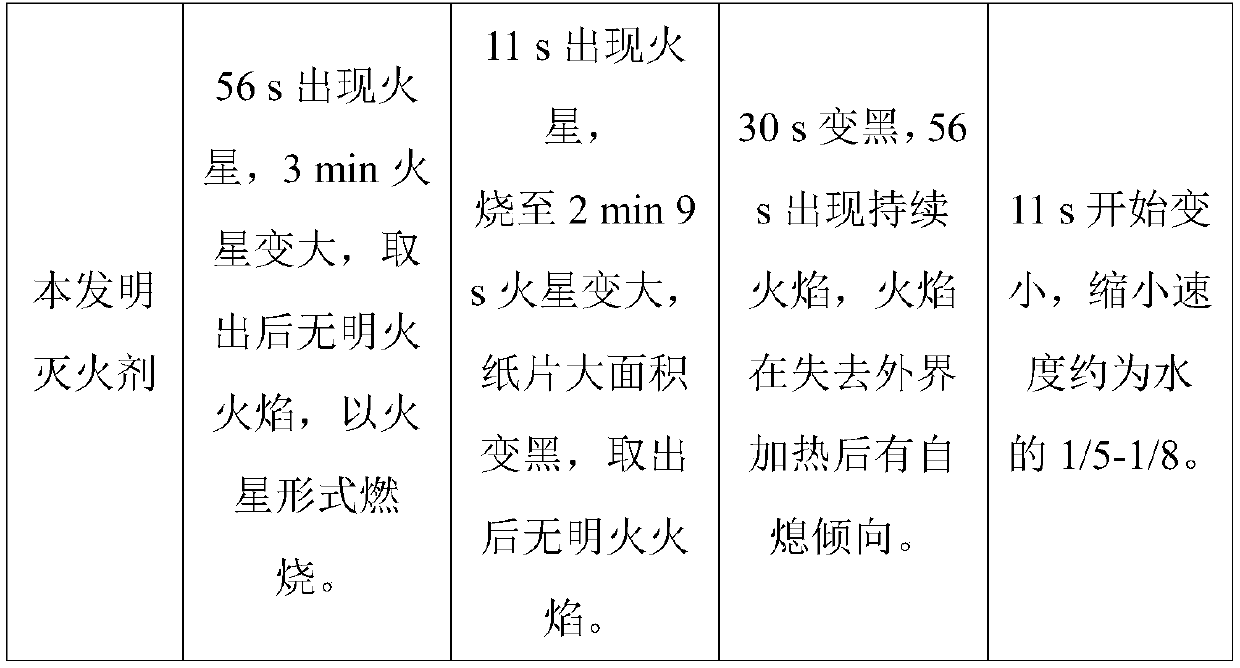

Adhering type water-based fire extinguishing agent for vertical surface solid fire

The invention relates to an adhering type water-based fire extinguishing agent for a vertical surface solid fire. A formula of the fire extinguishing agent comprises 3-10% of one or more than two of potassium acetate, potassium bromide, potassium oxalate or potassium bicarbonate, 0.1-0.5% of a non-ionic surface active agent, 1-5% of sodium carboxymethylcellulose, 1-5% of sodium silicate, 0.5-2% ofsodium polyacrylate, 0.1-0.3% of a calcium-magnesium ion complexing agent and the balance water. The fire extinguishing agent will greatly improves the fire extinguishing efficiency of the vertical surface solid fire.

Owner:应急管理部天津消防研究所

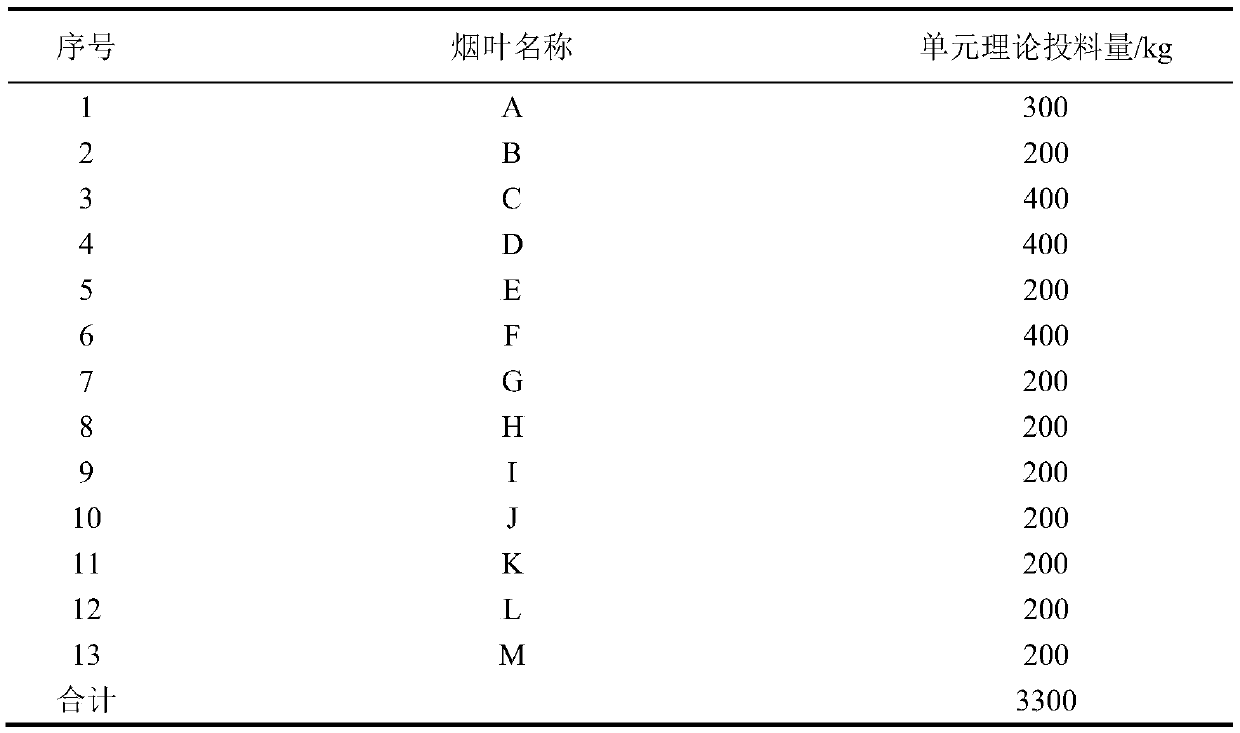

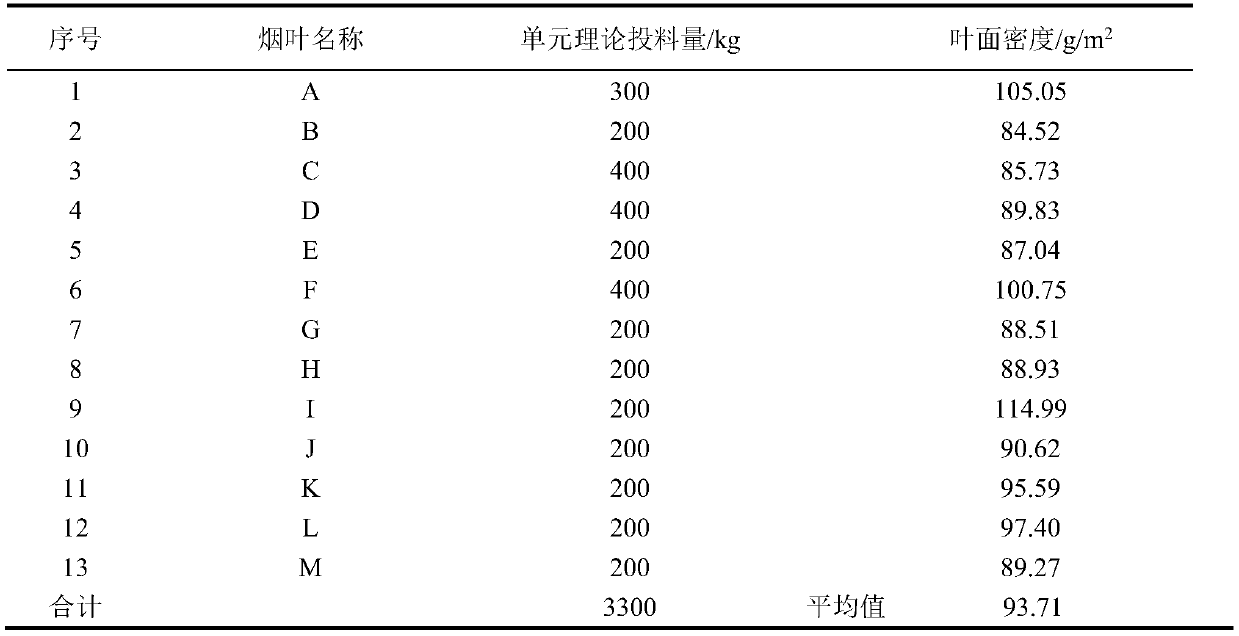

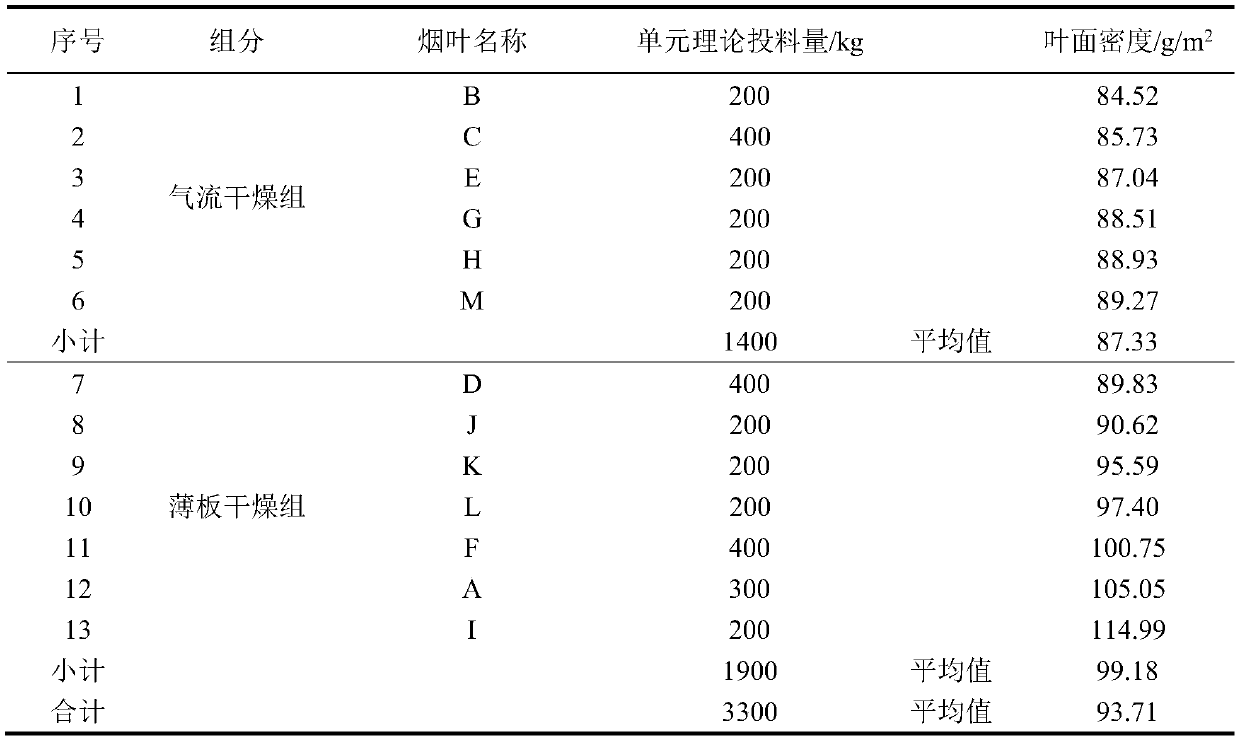

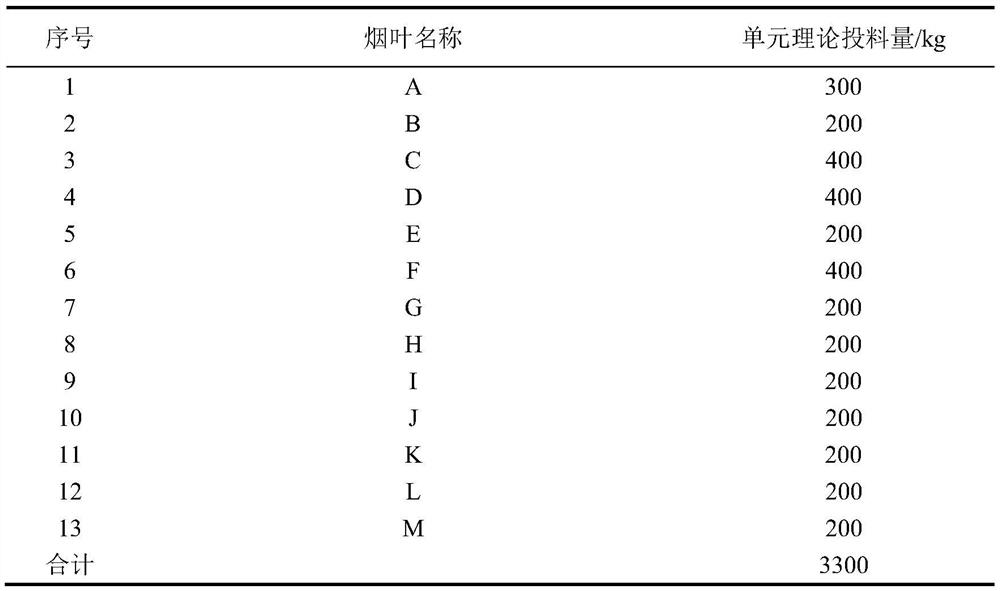

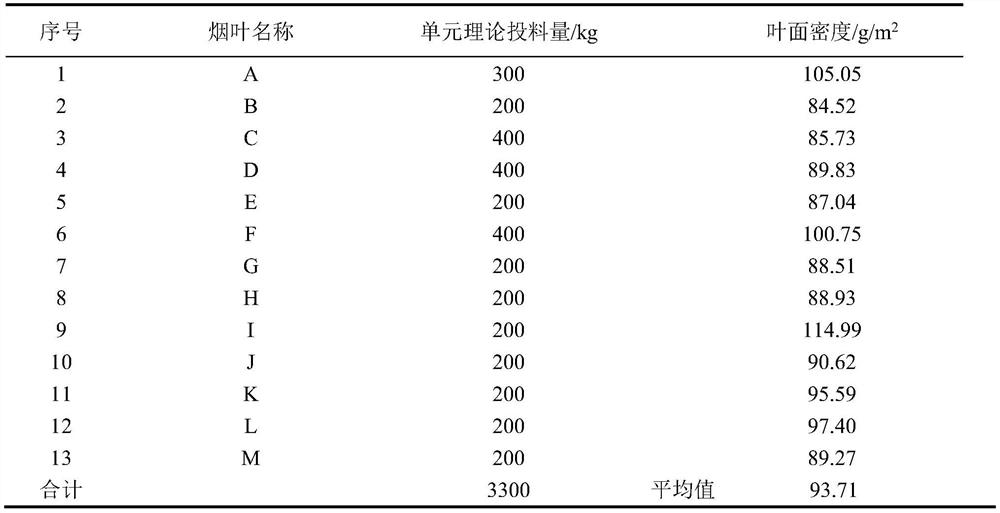

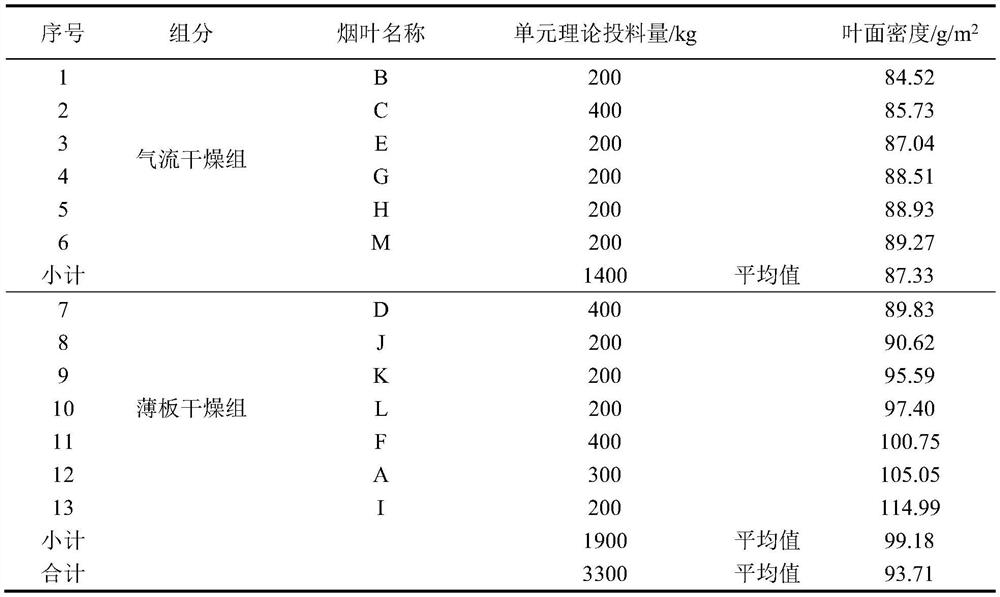

Method for grouping tobacco leaf raw materials in cigarette leaf group formula

ActiveCN111567844AImprove targetingEasy to get resultsTobacco preparationManufacturing computing systemsHorticultureBotany

The invention discloses a method for grouping tobacco leaf raw materials in a cigarette leaf group formula. The tobacco leaf raw materials are grouped according to the leaf surface density of tobaccoleaves of various grades. The leaf surface density index in the tobacco leaf quality characteristics is used as the key index of the leaf group formula grouping; the method overcomes the defects thatin an existing method, artificial decision experience is mainly used, reliable sensory and chemical evaluation guidance bases are lacked, key procedure technological parameters in the tobacco primaryprocessing process are designed in a targeted mode, the quality level of the processing technology is further exerted, and the quality of cigarette products is stabilized and improved. And the leaf surface density of the tobacco leaves is an index which is easy to obtain a result in numerous quality characteristics of the tobacco leaves, and the method has relatively strong operability.

Owner:CHINA TOBACCO ANHUI IND CO LTD

Rare earth treatment device

ActiveCN110669936ASlow dehydrationThoroughly dehydratedElectrolysis componentsSurface treatment compositionsElectrolysisEngineering

The invention relates to a treatment device, and particularly relates to a rare earth treatment device. The technical problem to be solved is to provide the rare earth treatment device. The rare earthtreatment device comprises a heat insulation crucible, an electrolysis crucible, electrodes, a condensation separation device, a high-temperature purification device and a fluorine gas recovery device, wherein the high-temperature purification device is arranged at the top end of an electrolysis chamber, and the left end of the high-temperature purification device is connected with the condensation separation device; and the fluorine gas recovery device is arranged at the right end of the electrolysis chamber. The rare earth treatment device aims at solving the problem that the metal neodymium residual in the crucible after electrolysis is separated from other auxiliary electrolytic raw materials through a complex method when an existing neodymium metal treatment device is in use, and a large amount of time is consumed. The rare earth treatment device achieves the effects of thoroughly drying crystal water through a " friction wheel " slow-speed rotation, recovering fluorine gas fromoutside to prepare hydrofluoric acid for glass etching, finally recovering the auxiliary raw materials, protecting the device and creating additional value.

Owner:包头市金为达稀土材料有限公司

A Firing Process for Improving the Variable Rate of Nixing Pottery Kiln

InactiveCN104150875BSlow dehydrationReduce the temperatureClaywaresTemperature differenceEngineering

The invention discloses a firing technique for enhancing kiln transformation ratio of Nixing pottery, which comprises the following steps: 1) putting a dried billet into a kiln, gradually heating to 50-100 DEG C, and keeping the temperature for 24-36 hours; 2) heating to 500-600 DEG C by 55-70 DEG C an hour; 3) heating to 750-850 DEG C by 90-110 DEG C an hour, closing the air holes of the kiln, and adding the kiln transformation material into the kiln; 4) heating to 1080-1150 DEG C by 90-110 DEG C an hour, wherein the heating speeds of the heating tubes are sequentially lowered from bottom to top in the kiln; and 5) cooling, and taking out the fired billet. In the high-temperature firing stage, the temperature difference appears in the kiln, so that the atmosphere of the reduction reaction is more violent; and the temperature is raised once an hour, so that the temperature in the kiln is changed, thereby enhancing the kiln transformation ratio.

Owner:QINZHOU DENGFENG CERAMIC ART

A kind of drying method of honeysuckle

InactiveCN103822442BBrightness value increasedReduce browningDrying using combination processesDrying solid materials with heatMetallurgyPhysical chemistry

The invention discloses a method for drying honeysuckles. The method includes placing screened fresh honeysuckles into color-protecting solution; laying the honeysuckles on stainless steel screen cloth after the color-protecting solution on the honeysuckles is drained, and placing the stainless steel screen cloth in a drying chamber of a heat pump drying machine; setting the temperature of the drying chamber at 40-60 DEG C, setting an air speed of the drying chamber at 1-2.5m / s and setting the concentration of oxygen in the drying chamber at 5-21%; filling the drying chamber with nitrogen for 3-5 minutes at intervals of 20-30 minutes in drying procedures, keeping the required concentration of the oxygen in the drying chamber unchanged, and drying the honeysuckles for 6-10 hours to obtain the honeysuckles which are dried by the aid of heat pumps; placing the screen cloth with the honeysuckles into a microwave generator after the honeysuckles are dried by the aid of the heat pumps, and drying the honeysuckles by the aid of microwaves until the moisture contents of the honeysuckles are lower than or equal to 12%; spreading the honeysuckles in cool, clean and ventilation positions to temper the honeysuckles; loading the honeysuckles in compound zip-lock bags, and filling the insides of the bags with nitrogen so that the concentration of oxygen in each bag is lower than or equal to 5%. The drying chamber of the heat pump drying machine is preheated for at least 30 minutes before the stainless steel screen cloth is placed in the drying chamber. The method has the advantages that a manufacturing process is simple, the cost is low, and the quality of products are stable; a brightness value L of the honeysuckles manufactured by the method is larger than 60, the total phenol content of the honeysuckles is higher than 0.5%, a chlorogenic acid loss rate is lower than 20%, and the method has obvious merits, an important application prospect and high popularization utilization value.

Owner:HENAN UNIV OF SCI & TECH

Retarded cement

InactiveCN107487993ASlow dehydrationReduce water evaporation rateDodecacalcium hepta-aluminateAluminium sulfate

The invention relates to the technical field of building materials, and discloses a retarded cement, which comprises the following composition by weight ratio of raw materials: 10-15 parts of dicalcium silicate, 12-18 parts of dodecacalcium heptaaluminate, and 3.5-5 parts of calcium aluminum feldspar , 2-4.5 parts of calcium sulfate, 0.5-1.2 parts of aluminum sulfate, 1.3-2.1 parts of soda, 0.1-0.8 parts of sodium chloride, 0.05-0.15 parts of nano-titanium dioxide, and 0.5-1.5 parts of mechanical binder. The use of the retarded cement slows down the evaporation rate of water in the concrete at high temperature, reduces the solidification rate of the concrete, and ensures the molding effect and quality of the concrete.

Owner:CHENGDU FANXINJIA TECH

Mine Fire Extinguishing Material Additive and Its Application

ActiveCN107308583BLow costNo pollution in the processDust removalFire preventionSuper absorbentSuspending Agents

The invention discloses a mining fire extinguishing material additive and application of the mining fire extinguishing material additive. The mining fire extinguishing material additive is prepared from, by weight, 40-80 parts of silicate materials, 0.1-5 parts of tackifier, 1-10 parts of dispersing agent, 5-20 parts of surfactant, 1-10 parts of suspending agent, 1-10 parts of super absorbent polymer and 1-10 parts of diluter. The mining fire extinguishing material additive has the advantages of being prepared from the easy-to-obtain raw materials, and being low in cost, easy to implement, good in gelatination effect, high in water retaining capacity, low in water loss speed, applicable to being added into coal ash, yellow mud, white mud and other underground coal mine filling grouting materials and excellent in fire preventing and extinguishing performance.

Owner:北票天宝耐火材料有限公司

Production method for waterproof pig-skin shoe upper leather

InactiveCN107488757AReduce lossesGood degreasing effectPre-tanning chemical treatmentLeather degreasingHexamethylenetetramineChlorinated paraffins

The invention relates to the technical field of animal fur processing, in particular to a production method for waterproof pig-skin shoe upper leather. Specifically, sodium carboxymethyl cellulose, borax, diethylene glycol and water are mixed to obtain depilation liquid, and pigskin is depilated; urotropine, nitroglycerin, salt, polyferric sulfate, diethylene glycol monooctyl ether and water are mixed to obtain a degreasing agent, and the pigskin is degreased; nitrocellulose, chlorinated paraffin, ethanol with the concentration being 80-82% and epoxy soybean oil are uniformly mixed to obtain a waterproof agent, and the pigskin is subjected to filling watertightness; the pigskin obtained through filling is hung and subjected to still standing under the environment that the humidity is relatively 50-52% and the temperature is 33-36 DEG C till the wet content of the pigskin is 18-20%; and the pigskin is dried. The production method for the waterproof pig-skin shoe upper leather is simple, the obtained pigskin has the excellent waterproofness, soft and full hand feelings, a certain elasticity and the good mercerizing sense, and the leather obtaining rate is 92.88% or above.

Owner:安徽乐踏鞋业有限公司

Method for preparing one-dimensional aluminum oxide fibre by hydrothermal-flux technique

InactiveCN101182024BPromote crystallizationIncrease added valueNanostructure manufactureAluminium oxide/hydroxide preparationFiberAluminium hydroxide

Owner:TSINGHUA UNIV

An adhesive water-based fire extinguishing agent for vertical solid fires

The invention relates to an adhering type water-based fire extinguishing agent for a vertical surface solid fire. A formula of the fire extinguishing agent comprises 3-10% of one or more than two of potassium acetate, potassium bromide, potassium oxalate or potassium bicarbonate, 0.1-0.5% of a non-ionic surface active agent, 1-5% of sodium carboxymethylcellulose, 1-5% of sodium silicate, 0.5-2% ofsodium polyacrylate, 0.1-0.3% of a calcium-magnesium ion complexing agent and the balance water. The fire extinguishing agent will greatly improves the fire extinguishing efficiency of the vertical surface solid fire.

Owner:应急管理部天津消防研究所

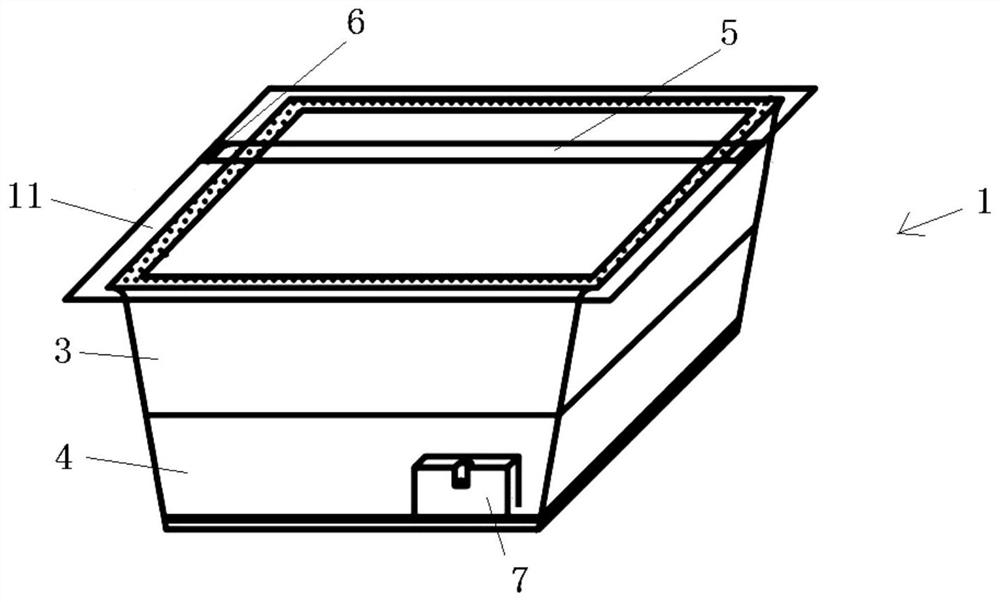

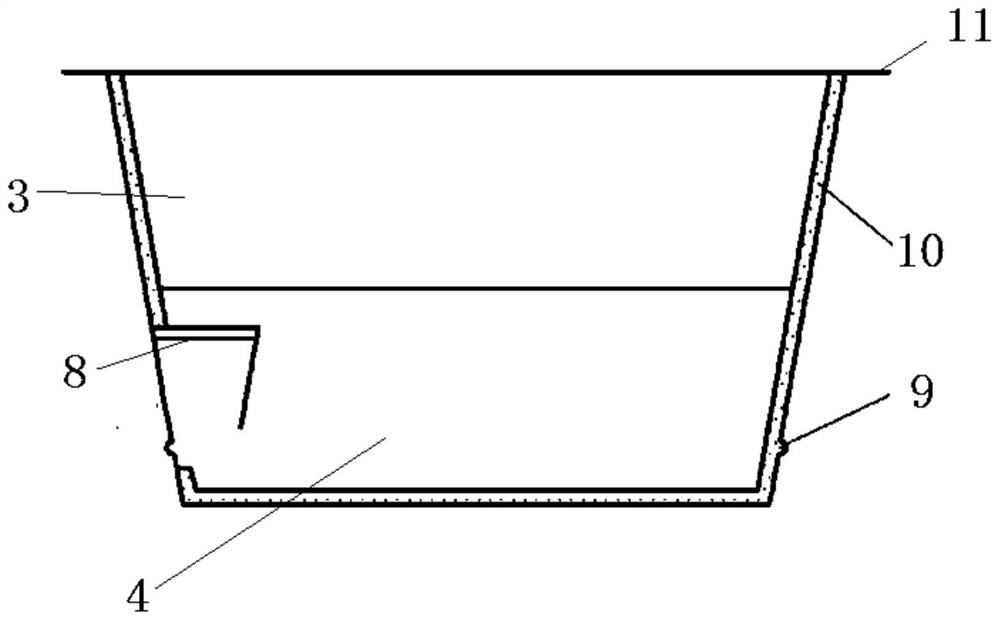

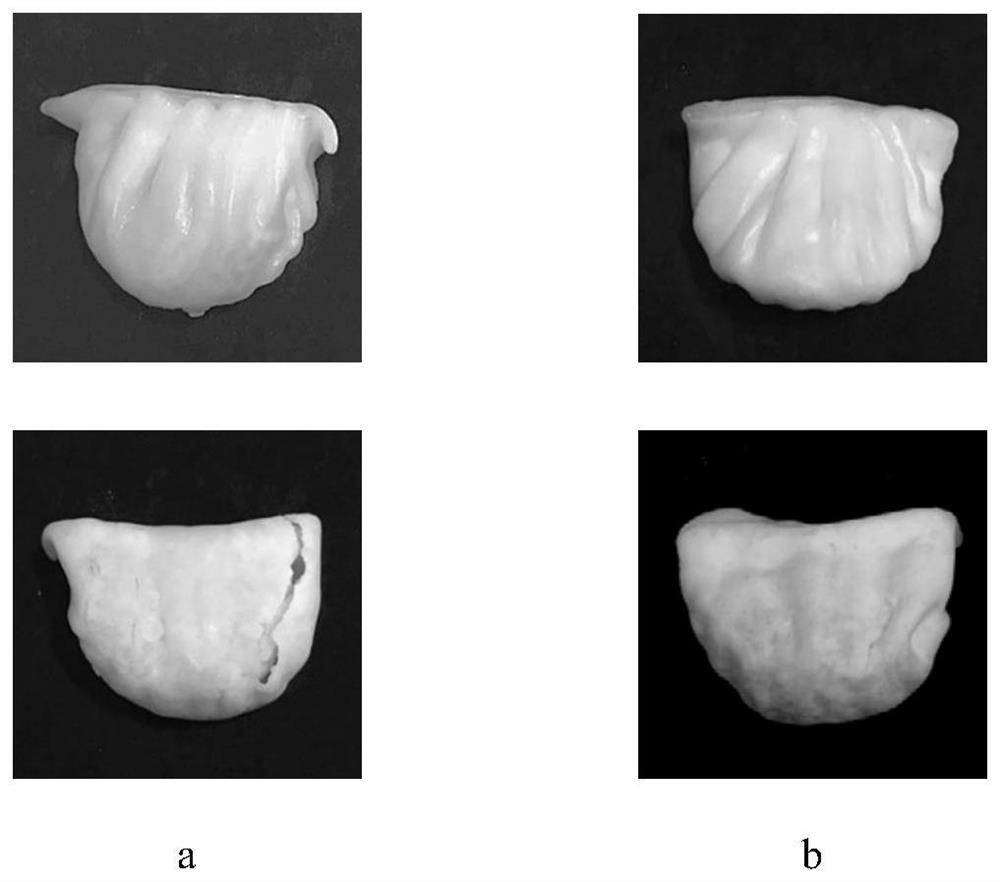

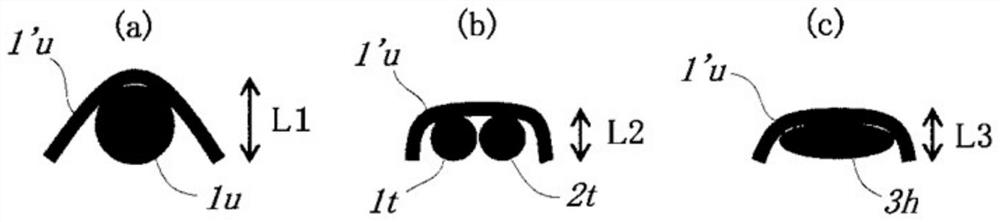

Pressure-controllable steam release packaging box for quick-frozen foods and heating method thereof

PendingCN113320835ASlow dehydrationSoft tasteClosuresContainers for heating foodThermodynamicsProcess engineering

The invention discloses a pressure-controllable steam release packaging box for quick-frozen foods and a heating method thereof. The packaging box is composed of a box body, a sealing film capable of releasing steam, a water filling nozzle, an end cover and the like. In the heating process, after the pressure in the box reaches a steam release pressure point, the film can automatically and slowly exhaust steam, and a certain steam pressure in the package is maintained. The packaging box mainly aims at the production and processing whole process of pre-steaming, quick-freezing, packaging, frozen storage and microwave curing of stuffed pastry, the internal space of the stuffed pastry is properly expanded through pre-steaming treatment, and a space is reserved for volume increment caused by subsequent stuffing freezing. Meanwhile, the automatic slow steam release pressure control function of the film capable of releasing steam is utilized, the film does not need to be uncovered in the reheating process, steam is introduced in the microwave heating and curing process by adding water before heating, moisture rapidly lost in the microwave process of the pastry is supplemented in time, the pastry is made to be in a high-damp-heat heating environment, and the quality problems of skin hardening and cracking, non-uniform temperature and the like of the stuffed pastry after conventional single microwave heating are solved.

Owner:SOUTH CHINA UNIV OF TECH

A method for grouping tobacco leaf raw materials in a cigarette leaf group formula

ActiveCN111567844BHigh inclusion contentImproves moisture retentionTobacco preparationManufacturing computing systemsHorticultureBotany

Owner:CHINA TOBACCO ANHUI IND CO LTD

Foam generating agent for wet dust collection

The invention discloses a foam producing agent for wet-type dust collection. According to the weight percentage, the foam producing agent for the wet-type dust collection comprises: 0.2%-6% of lauramide propyl glycine betaine, 0.15%-0.3% of hexadecyl tri-methyl ammonium bromide, 0.4%-1.3% of fatty alcohol-polyoxyethylene ether sodium sulfate, 1%-2% of sodium dodecyl benzene sulfonate, 0.2%-0.8% of dodecyl benzene glycine betaine, 0.2%-0.9% of fatty acid glycerolipid, 0.4%-2% of potassium polyacrylate, 1.5%-2.4% of perfluor octyl sulfo tetraethyl ammonium salt, 0.5%-1.5% of sucrose fatty acid ester, 0.3%-1.2% of diocytyl sulfo sodium succinate, and the balance is water. The foam producing agent for the wet-type dust collection is capable of cohering the dusts on the ground for a long time, avoiding the dusts from flying along with the wind because of the drying ground, and performing the collecting function to a duster for a long time. The foams produced by the foam producing agent for the wet-type dust collection have good biological degradability, and both the environmental protection coefficient and the safety coefficient are high.

Owner:SHANDONG UNIV OF SCI & TECH

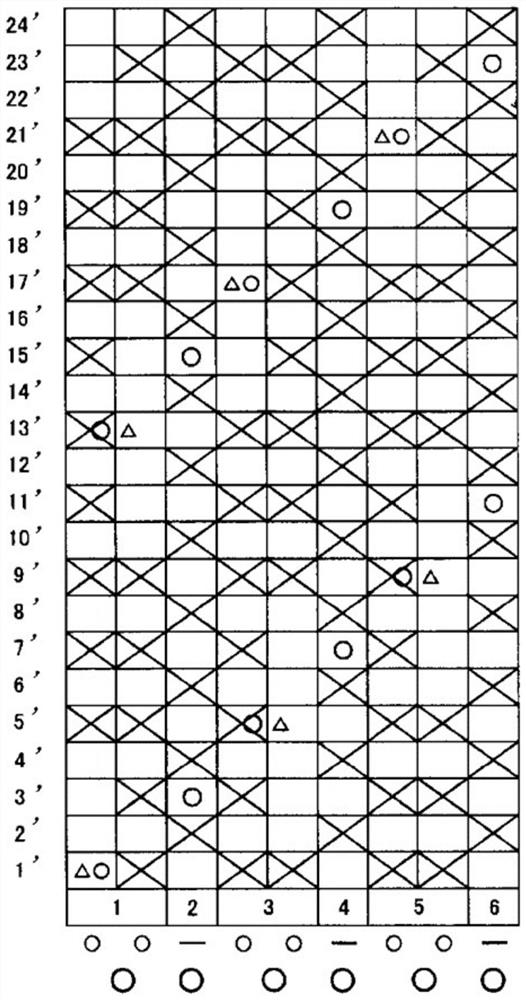

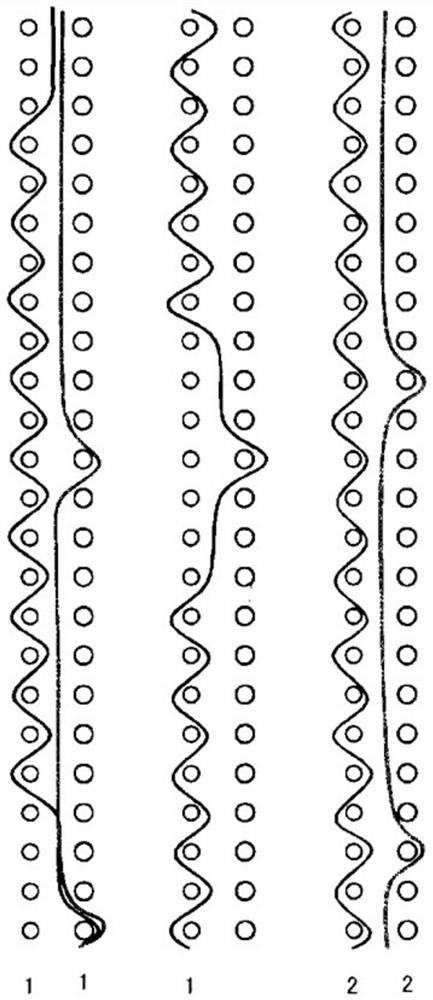

Industrial two-layer fabric

InactiveCN112513354AMeet the rigidityMeet wear resistanceMachine wet endMulti-ply fabricsYarnEngineering

Provided is an industrial two-layer fabric satisfying basic characteristics of a fabric, such as rigidity, wear resistance, dewaterability, mark suppression, and low water retention for reducing the amount of water retained. The industrial two-layer fabric pertaining to the present invention has at least a first structure and a second structure in the weave repeat thereof, the first structure being formed by a combination of two upper-surface-side warps and a single lower-surface-side warp, the second structure being formed by a single upper-surface-side warp and a single lower-surface-side warp, the first structure and the second structure being disposed adjacent to each other, the upper-surface-side warps in the first structure being formed by a warp binding yarn having the function of binding an upper-surface-side fabric and a lower-surface-side fabric, the combination of two upper-surface-side warps forming the first structure being disposed adjacent to each other and constitutinga partial rib weave at the surface of the upper-surface-side fabric, the diameter of the lower-surface-side warp being larger than the diameter of the upper-surface-side warp forming the first structure, and the upper-surface-side warp in the second structure being formed by a flat warp.

Owner:FILCON

A kind of fire extinguishing material for coal mine and preparation method thereof

The invention relates to extinguishing material for coal mine and a production method thereof and belongs to the field of coal mine materials for fire preventing and extinguishing. The extinguishing material is made by mixing well 5-15wt% of attapulgite, 1-5wt% of salt-resistant super-absorbent polymer and water. Preparation of the salt-resistant super-absorbent polymer includes: adding 3 parts of acrylic acid into an ice bath, neutralizing with sodium hydroxide, adding 4 parts of acrylamide to from a monomer, and sequentially adding potassium peroxodisulfate accounting for 0.25% of the total weight of the monomer and N, N-methylene bisacrylamide accounting for 0.25% of the total weight of the monomer; heating a water bath to 70 DEG C, allowing for reaction for 7h, and filtering and drying the cooled reaction product. Aggregate using the attapulgite as colloid is fine in suspendability and large in specific area, the obtained colloid is remarkably uniform and long in shelf life.

Owner:BEIJING UNIV OF TECH

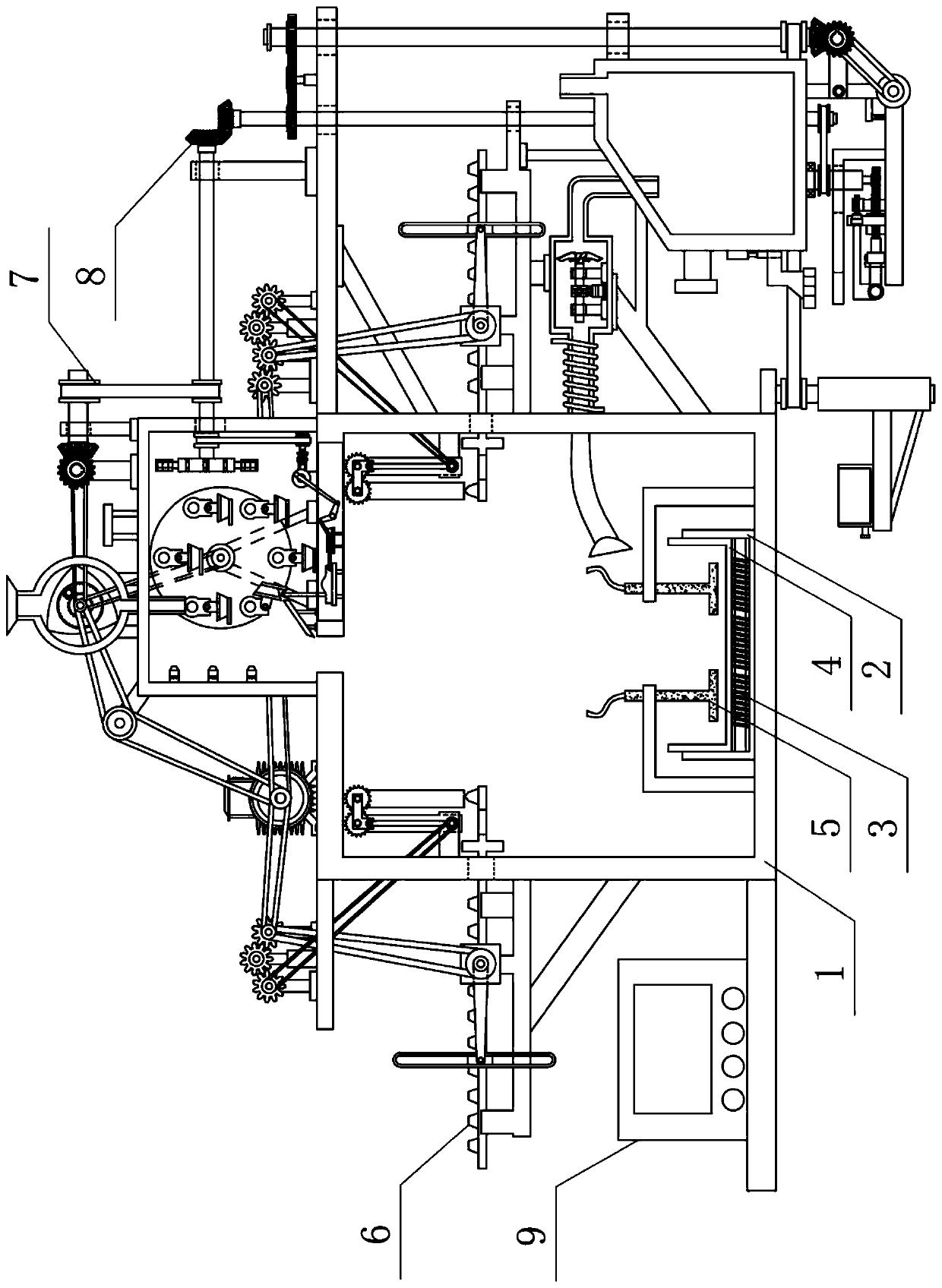

Gasified ash gel fire preventing and extinguishing material, use method and application thereof

PendingCN113350731AGood suspensionAvoid clogging pipesFire rescueFire extinguisherSocial benefitsEconomic benefits

The invention discloses a gasified ash gel fire preventing and extinguishing material as well as a use method and an application thereof, and belongs to the technical field of fire preventing and extinguishing materials. The fire preventing and extinguishing material is prepared from the following raw material components in percentage by mass: 0.25%-0.5% of a dispersion suspending agent, 1%-1.66% of a gelling agent, 1%-2% of a coagulation accelerator and the balance of ash slurry, wherein the ash slurry is prepared by mixing gasified ash and water, the water-ash mass ratio of the gasified ash to the water is 2:(0.4-2), and meanwhile, the invention further provides the use method and the application of the material. According to the fire preventing and extinguishing material, the optimal material ratio is developed, the fire preventing and extinguishing level of a goaf is comprehensively improved, the fire preventing and extinguishing cost is greatly reduced, the reliability, pertinence and effectiveness of the fire preventing and extinguishing technology are improved, and huge economic benefits and social benefits are achieved.

Owner:XIAN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com