Method for preparing one-dimensional aluminum oxide fibre by hydrothermal-flux technique

A technology of alumina fiber and flux, which is applied in the field of preparation of inorganic chemical materials, can solve the problems of many holes, poor shape, uneven thickness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

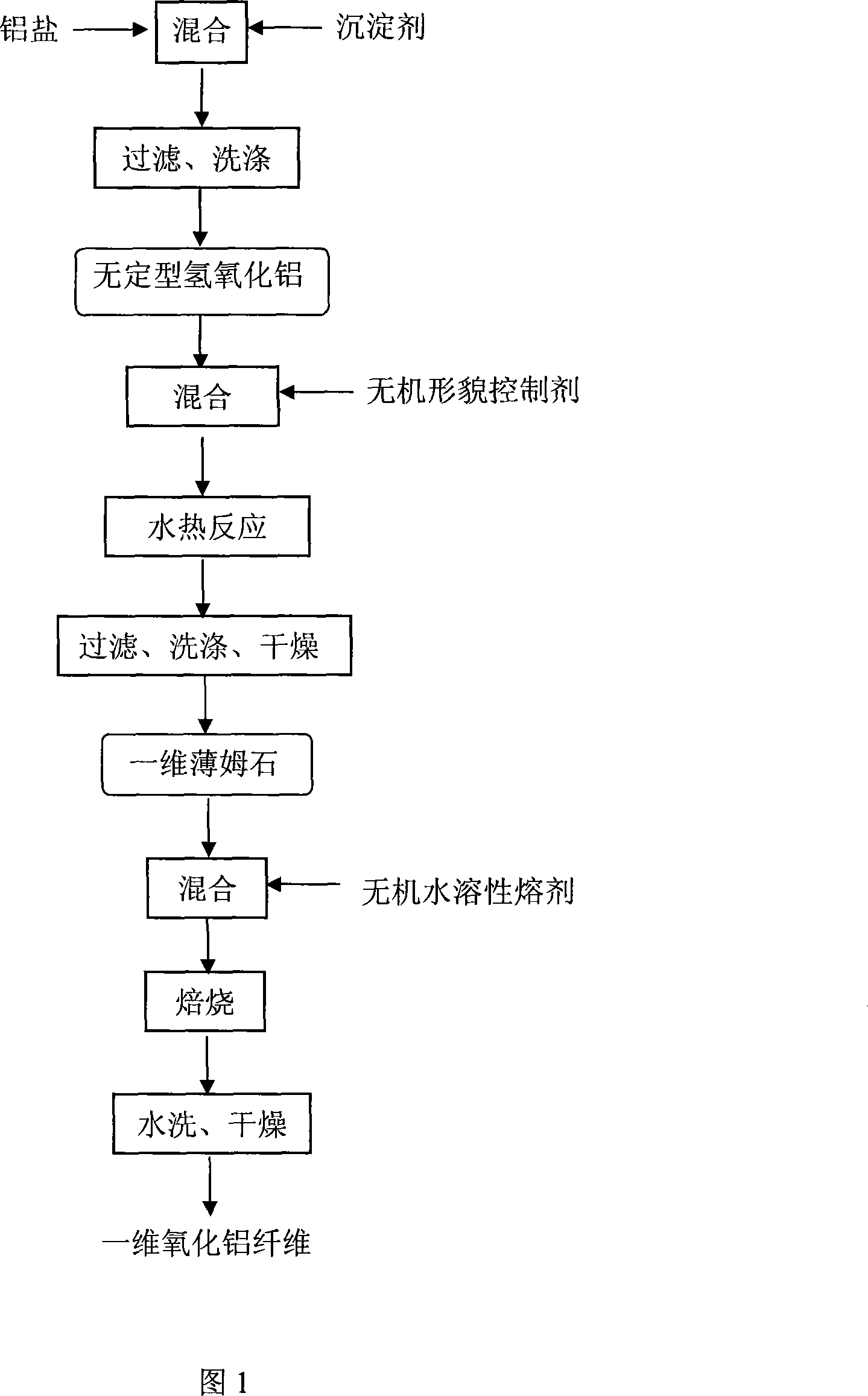

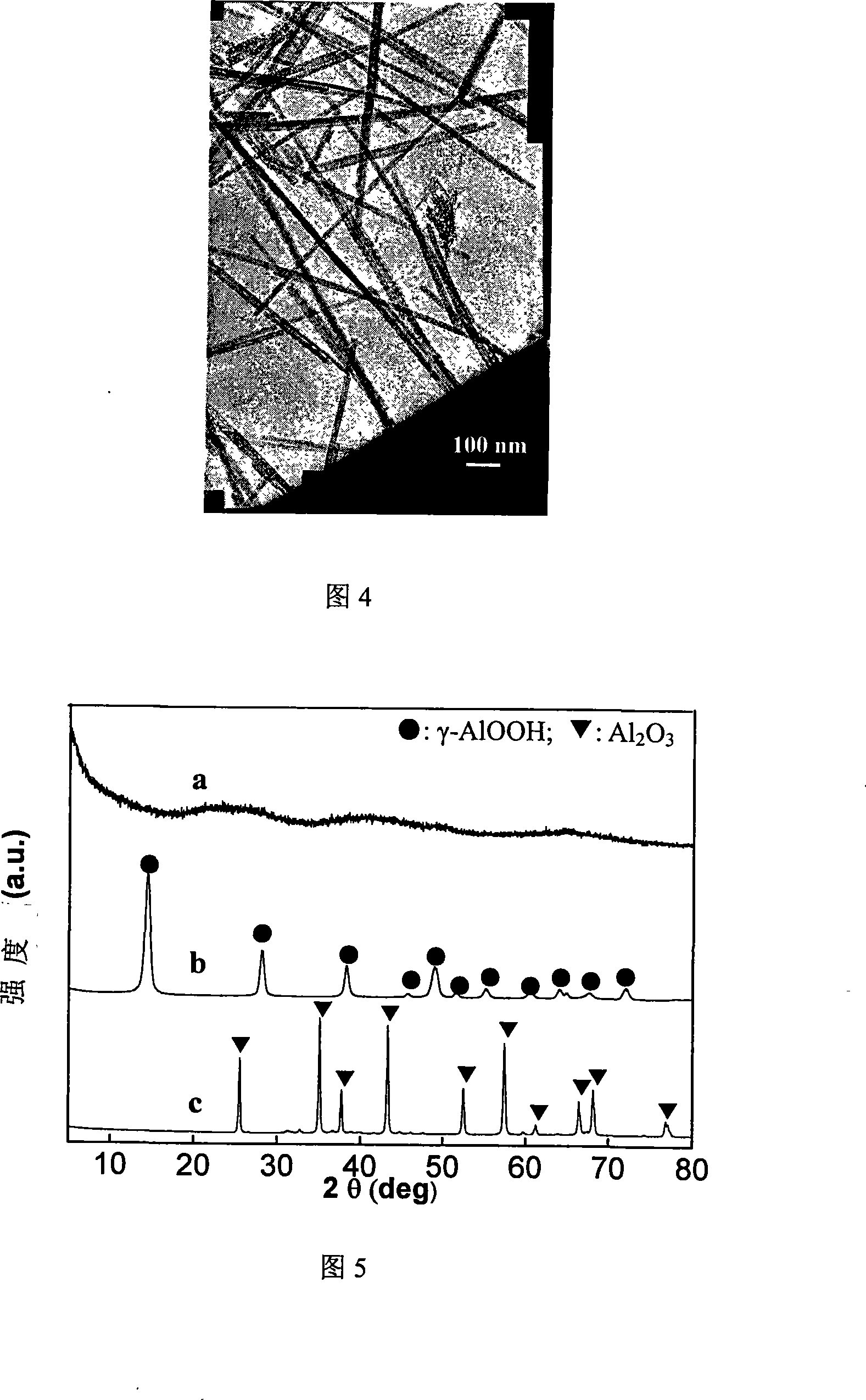

[0021] The invention provides a simple and feasible new method for preparing one-dimensional alumina fiber. The basic idea: first prepare the amorphous aluminum hydroxide precursor at room temperature, and then use the inorganic morphology control agent to selectively adsorb under hydrothermal conditions to achieve directional growth of γ-AlOOH to obtain one-dimensional γ-AlOOH with high aspect ratio; use multi-stage Slow heating and flux roasting methods realize low-temperature and slow dehydration and structural reformation of one-dimensional γ-AlOOH, and obtain one-dimensional γ-AlOOH with a diameter of 10-100nm, a length of 0.5-10μm, an aspect ratio of 50-200, regular morphology, and good crystallization. Al 2 o 3 fiber. The method has the advantages of simple process, low cost and easy popularization. The resulting alumina fiber has superior performance and high added value, and can be used as a reinforcing material in aluminum alloy, ceramics, plastics, rubber and oth...

Embodiment 1

[0031] Prepare 100 milliliters of 0.5 mol / liter aluminum chloride solution, 100 milliliters of 1.5 mol / liter ammonia solution, and 50 milliliters of 1% (w / v) sodium sulfate solution. Add ammonia solution (2 ml / min) to aluminum chloride solution at 25°C under stirring (300 rpm) to obtain amorphous aluminum hydroxide suspension. Filter and wash the suspension, then add the precipitate and sodium sulfate solution into the autoclave, conduct a hydrothermal reaction at 250°C with stirring (100 rpm) for 8 hours, cool, filter, and wash to obtain γ-AlOOH hydrothermal intermediate Product; mix the γ-AlOOH hydrothermal intermediate product with sodium chloride, control the weight ratio of the two to 100:5, place the mixture in a muffle furnace, raise the temperature (2°C / min) to 250°C and keep it for 1 hour, then Raise the temperature (1°C / min) to 600°C and keep it warm for 0.1 hour, then continue to raise the temperature (5°C / min) to 800°C and keep it warm for 1 hour. The calcined pro...

Embodiment 2

[0033] Prepare 100 ml of 1 mol / liter aluminum sulfate solution, 100 ml of 4 mol / liter sodium hydroxide solution, and 50 ml of 10% (w / v) potassium sulfate solution. Add sodium hydroxide solution (5 ml / min) to aluminum sulfate solution at 30°C under stirring (50 rpm) to obtain amorphous aluminum hydroxide suspension. Filter and wash the suspension, then add the precipitate and potassium sulfate solution into the autoclave, conduct a hydrothermal reaction at 300°C with stirring (50 rpm) for 30 hours, cool, filter, and wash to obtain γ-AlOOH hydrothermal intermediate Product; mix the γ-AlOOH hydrothermal intermediate product with potassium chloride, control the weight ratio of the two to 100:10, place the mixture in a muffle furnace, raise the temperature (0.5°C / min) to 200°C and keep it for 0.5 hours, then Raise the temperature (0.5°C / min) to 650°C and keep it warm for 1 hour, then continue to raise the temperature (1°C / min) to 900°C and keep it warm for 2 hours. The calcined pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com