Mining fire extinguishing material additive and application thereof

A technology of fire extinguishing materials and additives, applied in fire prevention equipment, mining equipment, fire prevention, etc., can solve the problems of high cost, poor gelling effect, etc., and achieve the effects of slow water loss, strong water retention capacity, and excellent suspension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

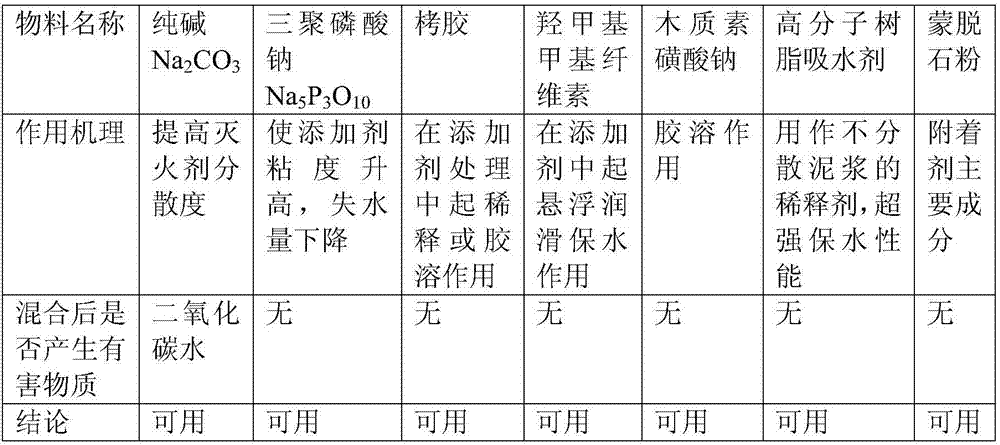

Method used

Image

Examples

Embodiment 1

[0027] Weigh 65g montmorillonite powder, 4g sodium carbonate, 1g sodium tripolyphosphate, 5g tannin extract, 5g hydroxymethyl methylcellulose, 10g sodium lignosulfonate and 5g polymer water-absorbing resin, grind and mix until the powder is If the diameter is less than 200 μm, the mine fire extinguishing material additive can be obtained.

[0028]

Embodiment 2

[0030] Weigh 50g montmorillonite powder, 3g sodium carbonate, 0.5g sodium tripolyphosphate, 3g tannin extract, 3g hydroxymethyl methylcellulose, 7g sodium lignosulfonate and 3g polymer water-absorbing resin, grind and mix until powder The particle diameter is below 200 μm, and the mine fire extinguishing material additive is obtained.

Embodiment 3

[0032] Weigh 70g montmorillonite powder, 7g sodium carbonate, 2g sodium tripolyphosphate, 8g tannin extract, 8g hydroxymethyl methylcellulose, 13g sodium lignosulfonate and 8g polymer water-absorbing resin, grind and mix until the powder is If the diameter is less than 200 μm, the mine fire extinguishing material additive can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com