Quasi-gel valve controlled lead acid accumulator

A lead-acid battery, colloidal electrolyte technology, applied in the direction of lead-acid battery, lead-acid battery construction, sustainable manufacturing/processing, etc. Slow down the phenomenon of water loss, prolong the service life, the effect of slow water loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

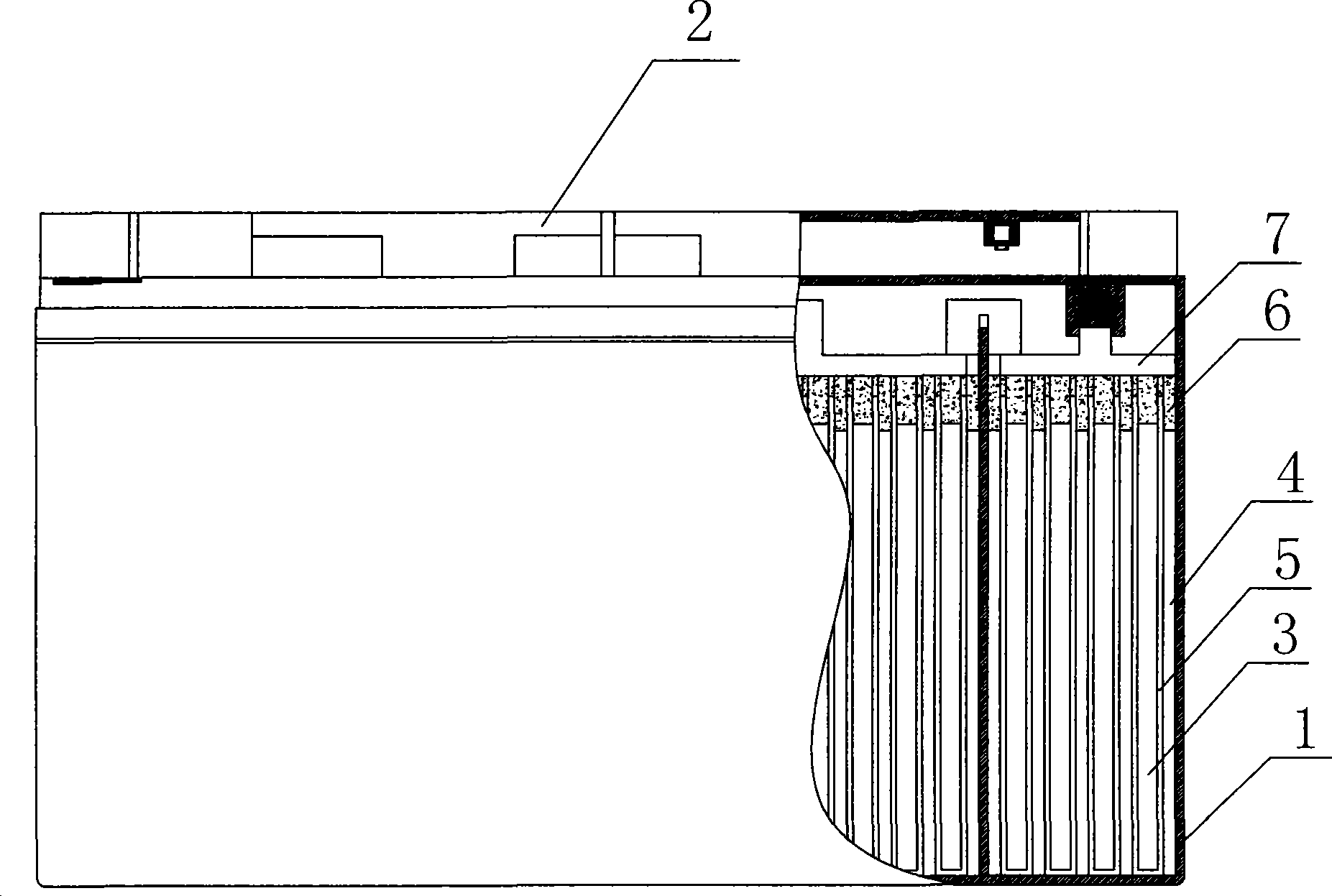

[0015] Such as figure 1 , a quasi-colloidal valve-regulated lead-acid battery, comprising a battery tank 1, a battery cover 2 arranged on the battery tank 1, a positive plate 3 and a negative plate 4 are arranged in the battery tank 1, and the positive plate 3 and the negative electrode An AGM separator 5 is arranged between the plates 4 , and a colloidal electrolyte protective layer 6 is arranged above the positive plate 3 , the negative electrode 4 and the AGM separator 5 in the battery tank 1 . The colloidal electrolyte protection layer 6 is prepared by using 3% nano fumed silicon dioxide, 60% deionized water, and 37% sulfuric acid. A bus bar 7 is arranged above the colloidal electrolyte protective layer 6 in the battery container 1 . The AGM separator 5 is used to absorb electrolyte. The combination of AGM separator and colloid overcomes the shortcomings of high internal resistance, high-current discharge performance and low-temperature discharge performance of colloidal...

Embodiment 2

[0017] The structure of this embodiment is the same as that of Embodiment 1, except that the colloidal electrolyte protective layer 6 is prepared by 10% nano fumed silicon dioxide, 50% deionized water, and 40% sulfuric acid.

Embodiment 3

[0019] The structure of this embodiment is the same as that of Embodiment 1, except that the colloidal electrolyte protective layer 6 is prepared by using 15% nano fumed silicon dioxide, 40% deionized water, and 45% sulfuric acid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com