Foam producing agent for wet-type dust collection

A foam generation, wet technology, applied in other chemical processes, chemical instruments and methods, etc., can solve the problems of weak acid and alkali resistance and hard water resistance, large average bubble diameter, long foam stability time, etc., to achieve biodegradability Good, excellent foaming power, effect of reducing surface tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Weigh respectively according to the following quality standards: lauryl amidopropyl betaine 2kg, cetyltrimethylammonium bromide 1.5kg, fatty alcohol polyoxyethylene ether sodium sulfate 4kg, sodium dodecylbenzenesulfonate 10kg, ten Dialkylbenzene betaine 2kg, fatty acid glyceride 2g, potassium polyacrylate 4g, perfluorooctylsulfonyltetraethylammonium salt 15g, sucrose fatty acid ester 5g and sodium dioctylsulfosuccinate 3g. Add the above formula raw materials into 951.5kg of clear water, and mix thoroughly to prepare 1000kg of foam generating agent for wet dust collection. The foam generated by the foam generating agent for wet dust collection has uniform texture and good water retention.

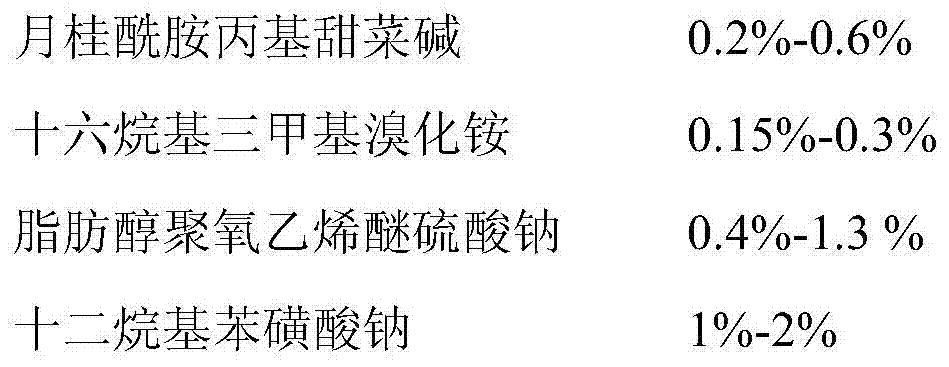

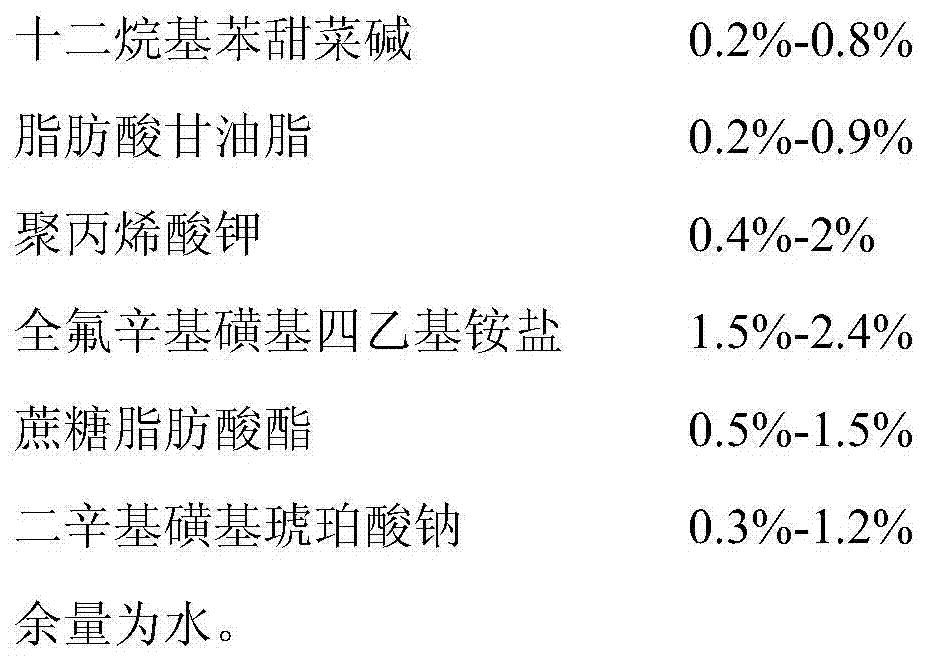

[0030] Among them, in this formula, the percentages of various raw materials are: lauryl amidopropyl betaine 0.2%, cetyltrimethylammonium bromide 0.15%, fatty alcohol polyoxyethylene ether sodium sulfate 0.4%, ten Sodium Dialkylbenzene Sulfonate 1.0%, Dodecyl Benzene Betaine 0.2%, F...

Embodiment 2

[0032] Weigh respectively according to the following quality standards: lauryl amidopropyl betaine 3.5kg, cetyltrimethylammonium bromide 2kg, fatty alcohol polyoxyethylene ether sodium sulfate 6kg, sodium dodecylbenzenesulfonate 13kg, ten Dialkylbenzene betaine 4kg, fatty acid glyceride 4g, potassium polyacrylate 8g, perfluorooctylsulfonyltetraethylammonium salt 19g, sucrose fatty acid ester 9g and sodium dioctylsulfosuccinate 6g. Add the above formula raw materials into 925.5kg of clear water, and prepare and form 1000kg of new mining dust-removing foam generating agent after fully mixing. The foam generated by the foam generating agent is large in number, uniform and fine, has a certain viscosity, and has excellent water retention performance.

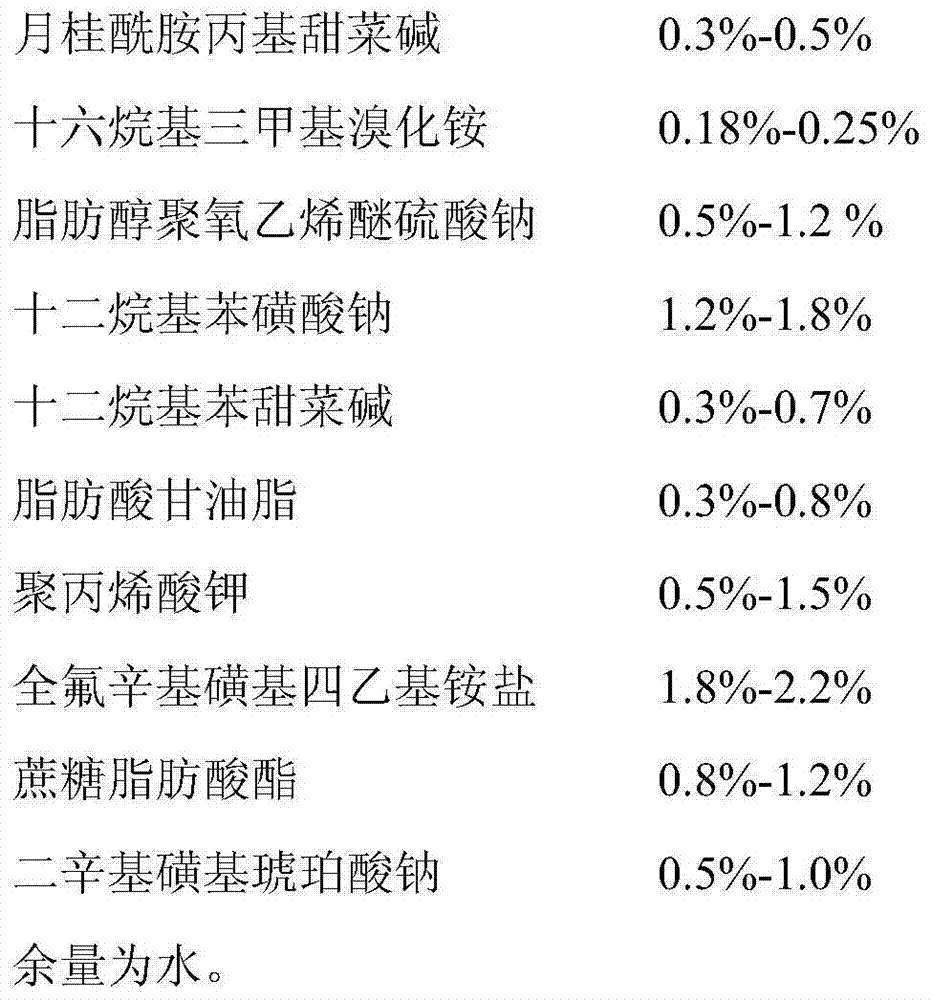

[0033] Among them, in this formula, the percentages of various raw materials are: lauryl amidopropyl betaine 0.35%, cetyltrimethylammonium bromide 0.2%, fatty alcohol polyoxyethylene ether sodium sulfate 0.6%, ten Sodium Dialkylbenzen...

Embodiment 3

[0035] Weigh respectively according to the following quality standards: lauryl amidopropyl betaine 4.5kg, cetyltrimethylammonium bromide 2.4kg, fatty alcohol polyoxyethylene ether sodium sulfate 10kg, sodium dodecylbenzenesulfonate 17kg, Dodecylbenzene betaine 6kg, fatty acid glyceride 7g, potassium polyacrylate 12g, perfluorooctylsulfonyltetraethylammonium salt 21g, sucrose fatty acid ester 11g and sodium dioctylsulfosuccinate 9g. Add the above formula raw materials into 900.1kg of clear water, and mix thoroughly to prepare 1000kg of foam generating agent for wet dust collection. The foam generated by the foam generating agent for wet dust collection has uniform texture and good water retention.

[0036] Among them, in this formula, the percentages of various raw materials are: lauryl amidopropyl betaine 0.45%, cetyltrimethylammonium bromide 0.24%, fatty alcohol polyoxyethylene ether sodium sulfate 1.0%, ten Sodium Dialkylbenzene Sulfonate 1.7%, Dodecyl Benzene Betaine 0.6%,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com