Method for preparing one-dimensional aluminum oxide fibre by hydrothermal-flux technique

A technology of alumina fiber and flux, applied in the field of inorganic chemical material preparation, can solve the problems of poor shape, many holes, uneven thickness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

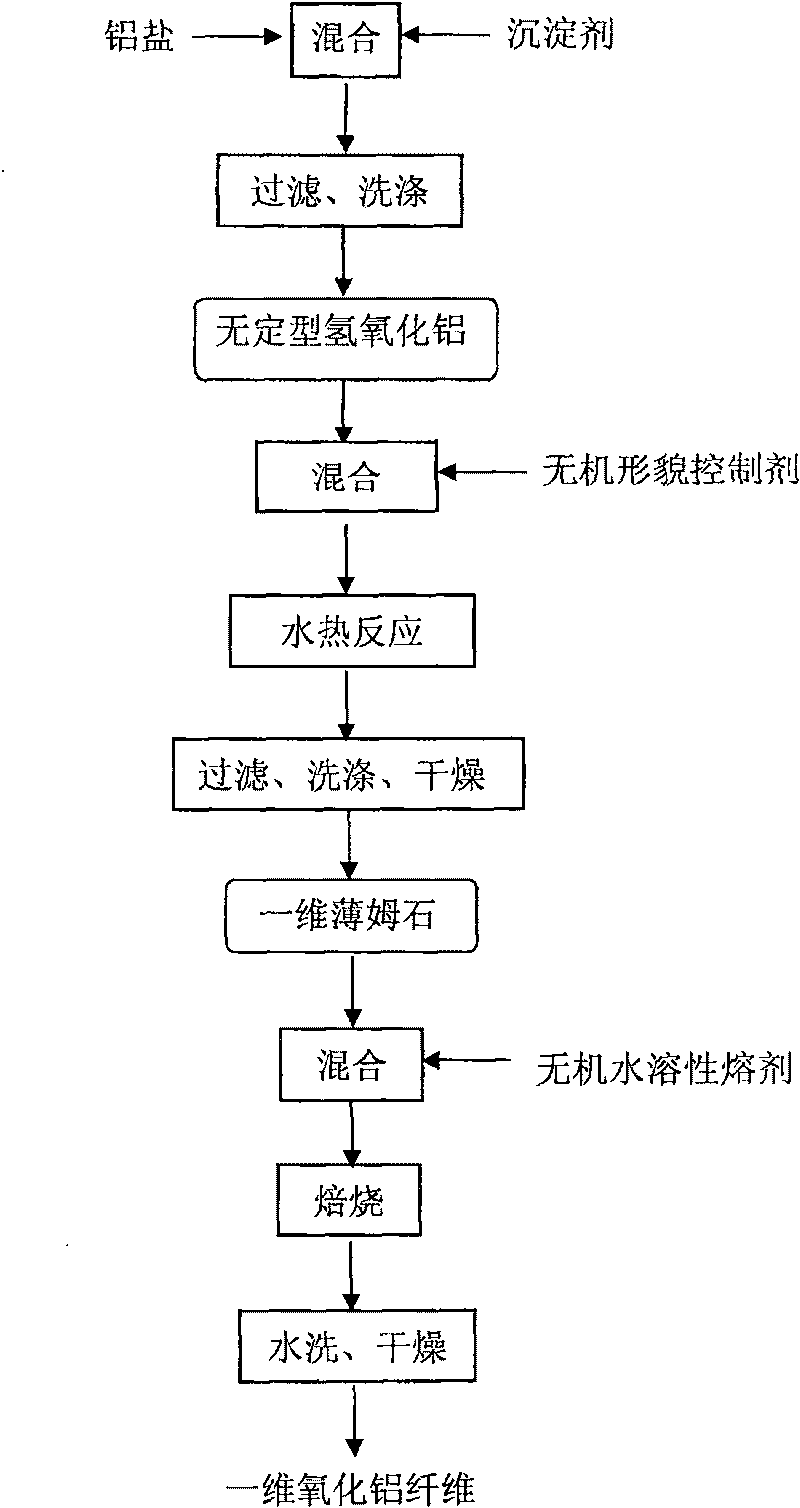

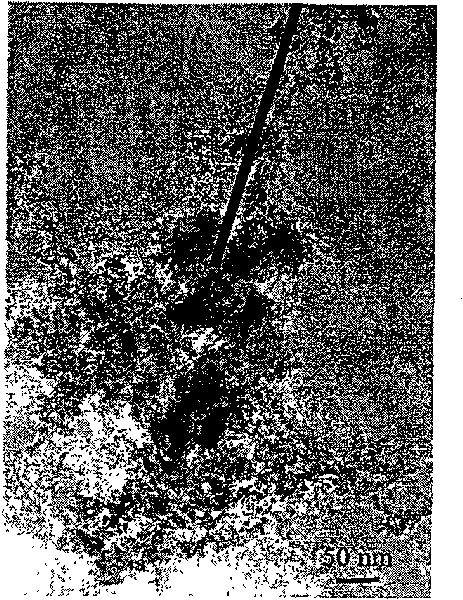

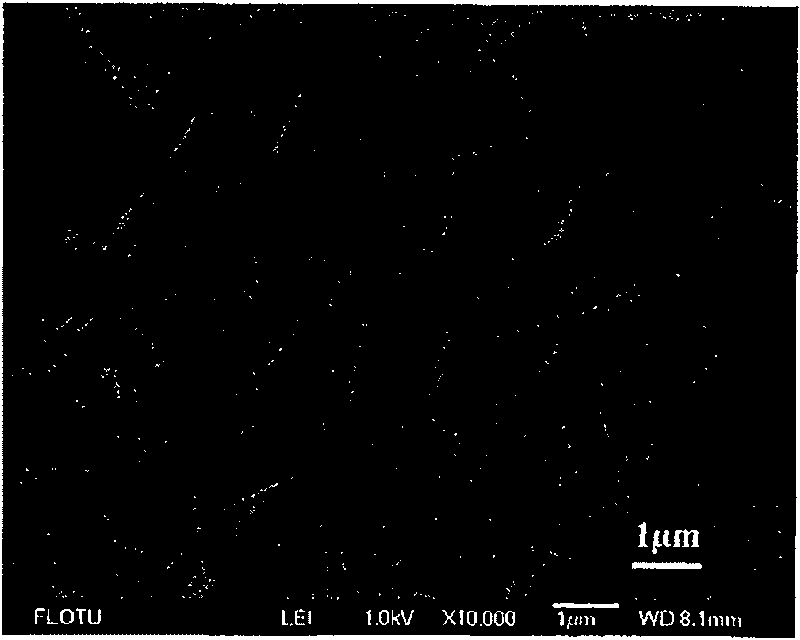

[0021] The invention provides a simple and feasible new method for preparing one-dimensional alumina fibers. The basic idea: firstly prepare amorphous aluminum hydroxide precursor at room temperature, and then use inorganic morphology control agent to selectively adsorb γ-AlOOH under hydrothermal conditions to achieve directional growth of γ-AlOOH to obtain one-dimensional γ-AlOOH with high aspect ratio; Slow heating and flux roasting methods realize the low-temperature slow dehydration and structural reforming of one-dimensional γ-AlOOH to obtain a one-dimensional one-dimensional with a diameter of 10-100nm, a length of 0.5-10μm, an aspect ratio of 50-200, regular morphology and good crystallization Al 2 O 3 fiber. The method has simple process, low cost and easy promotion. The alumina fiber thus obtained has superior performance and high added value, and can be used as a reinforcing material in industries such as aluminum alloy, ceramics, plastics, and rubber.

[0022] The pr...

Embodiment 1

[0031] Prepare 100 ml of 0.5 mol / liter aluminum chloride solution, 100 ml of 1.5 mol / liter ammonia solution, and 50 ml of 1% (w / v) sodium sulfate solution. Add the aqueous ammonia solution (2 ml / min) to the aluminum chloride solution at 25° C. and stirring (300 rpm) to obtain an amorphous aluminum hydroxide suspension. The suspension was filtered and washed, and then the precipitate and sodium sulfate solution were added to the autoclave. The reaction was hydrothermally reacted at 250°C and stirring (100 rpm) for 8 hours, cooled, filtered, and washed to obtain γ-AlOOH hydrothermal intermediate Product; Mix the γ-AlOOH hydrothermal intermediate product with sodium chloride, control the weight ratio of the two to 100:5, put the mixture in a muffle furnace, raise the temperature (2°C / min) to 250°C and keep it for 1 hour, then Increase the temperature (1°C / min) to 600°C and keep it for 0.1 hour, then continue to increase the temperature (5°C / min) to 800°C and keep it for 1 hour. T...

Embodiment 2

[0033] Prepare 100 mL of 1 mol / L aluminum sulfate solution, 100 mL of 4 mol / L sodium hydroxide solution, and 50 mL of 10% (w / v) potassium sulfate solution. Add the sodium hydroxide solution to the aluminum sulfate solution (5 ml / min) under stirring (50 rpm) at 30°C to obtain an amorphous aluminum hydroxide suspension. The suspension was filtered and washed, and then the precipitate and potassium sulfate solution were added to the autoclave. The reaction was hydrothermally reacted at 300°C and stirring (50 rpm) for 30 hours, cooled, filtered and washed to obtain γ-AlOOH hydrothermal intermediate Product; mix the γ-AlOOH hydrothermal intermediate product with potassium chloride, control the weight ratio of the two to 100:10, place the mixture in a muffle furnace, raise the temperature (0.5°C / min) to 200°C and keep it for 0.5 hours, then Increase the temperature (0.5°C / min) to 650°C and keep it for 1 hour, continue to increase the temperature (1°C / min) to 900°C and keep it for 2 h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com