Method and system for separating and classifying different parts of tobacco leaves

A technology of tobacco leaves and parts, applied in the directions of tobacco, tobacco preparation, application, etc., can solve the problems affecting the taste and taste of cigarette products, and achieve the effects of improving the quality of cigarette products, reducing the breaking rate, and improving the production environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

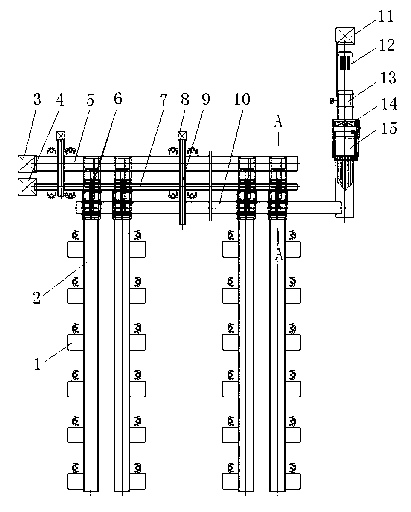

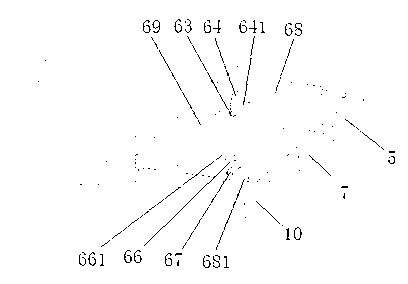

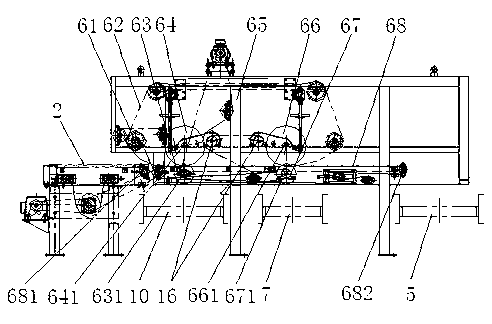

[0027] The system for separating and classifying different parts of tobacco leaves provided by the present invention includes a swing handle and leaf laying conveyor 2 for carrying out tobacco handle swinging or tobacco leaf laying in the conveying process, and one side of the swing handle leaf laying conveyor is arranged at intervals for stacking tobacco handles or Tobacco leaf feeder 1, to place the tobacco handle of feeder 1 on the pendulum leaf laying conveyor 2, or spread the tobacco leaves on the pendulum leaf laying conveyor 2, wherein, the outlet end of the pendulum leaf laying conveyor 2 A cutting and separating machine 6 is provided, and below the cutting and separating machine 6, a stem tobacco conveyor 10, a leaf tip tobacco conveyor 7, and a leaf-based tobacco conveyor 5 are arranged; a leaf-based tobacco conveyor 5, and a leaf-tip tobacco c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com