Induced phase transition method for the production of microparticles containing hydrophobic active agents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

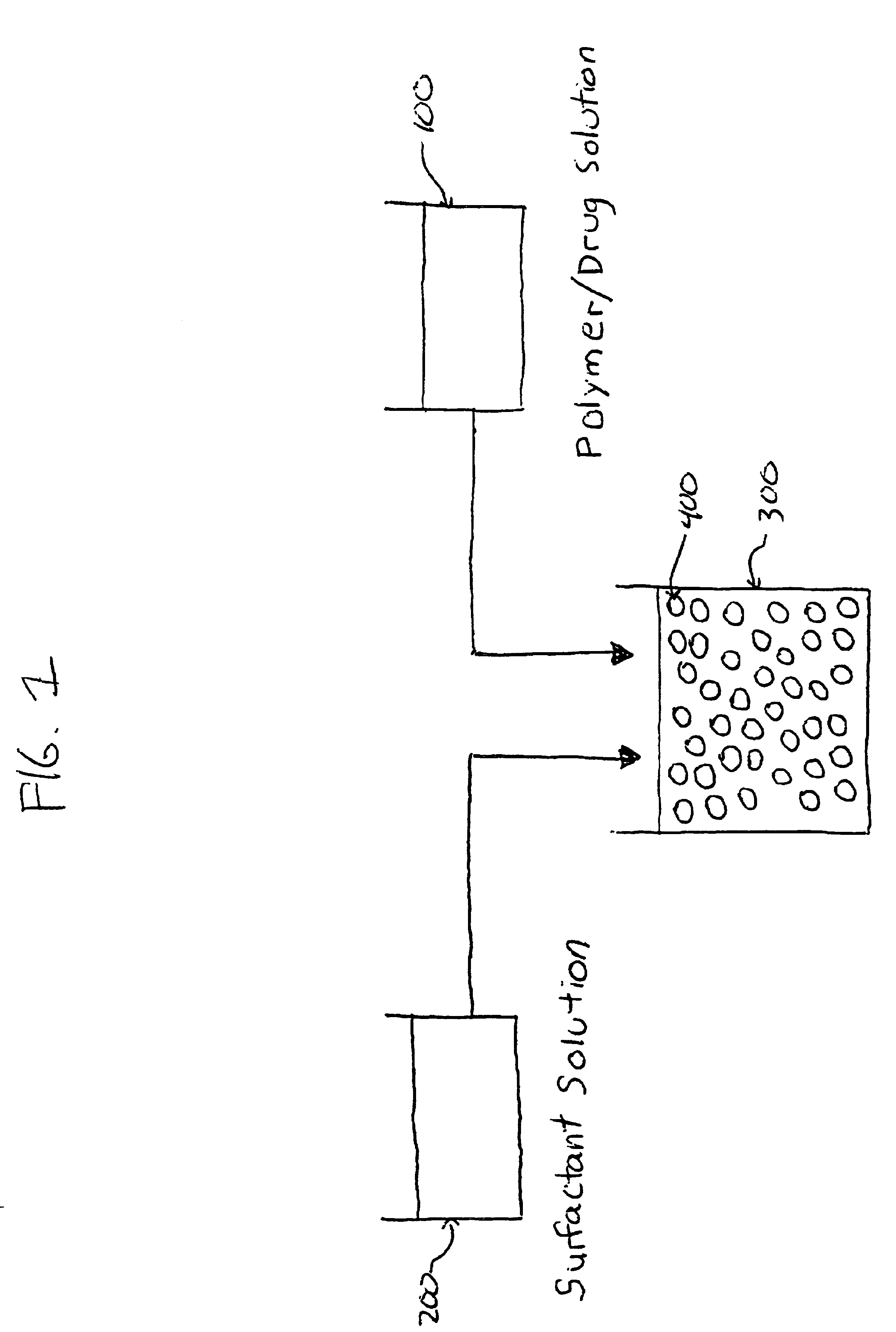

Method used

Image

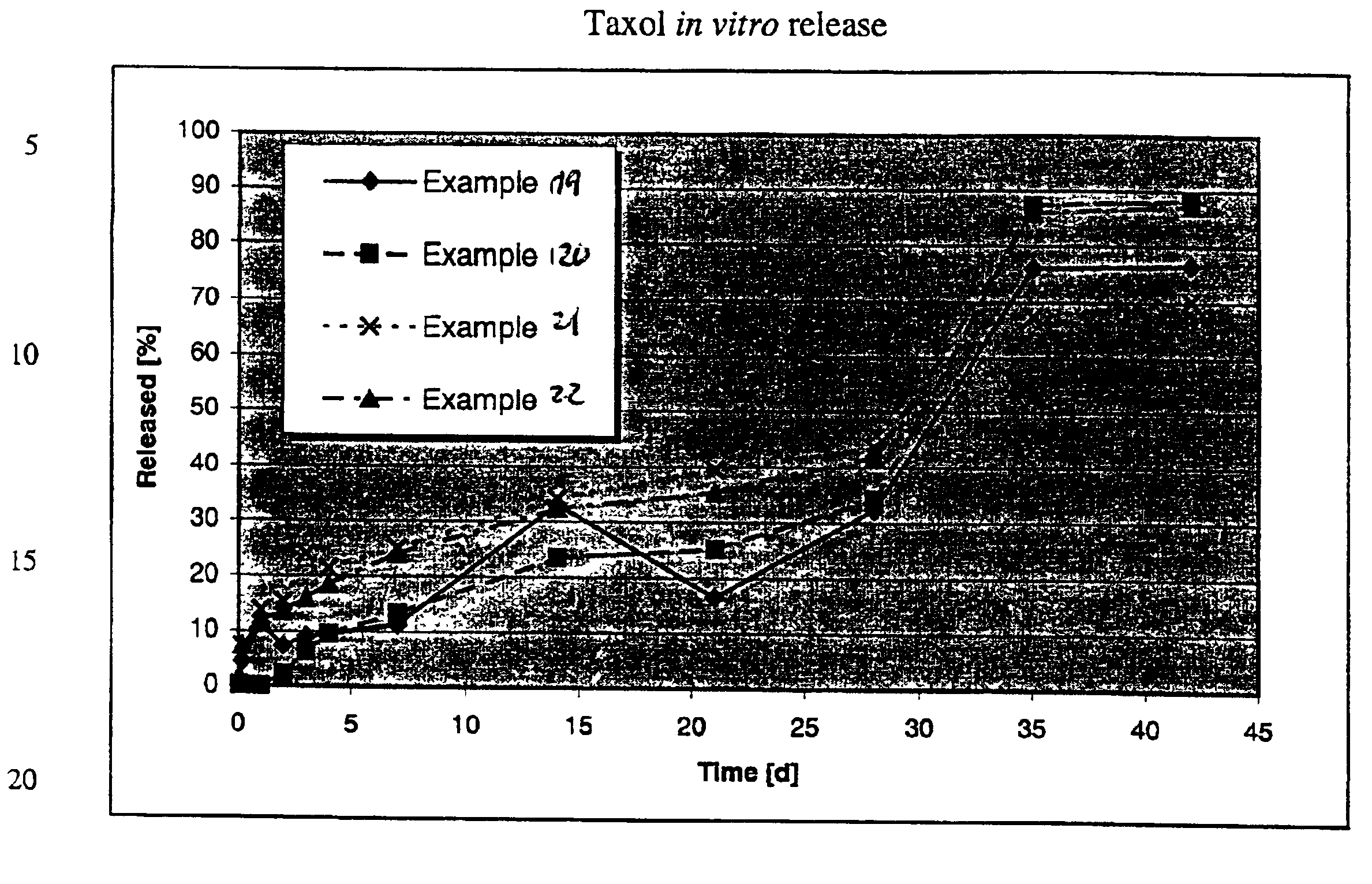

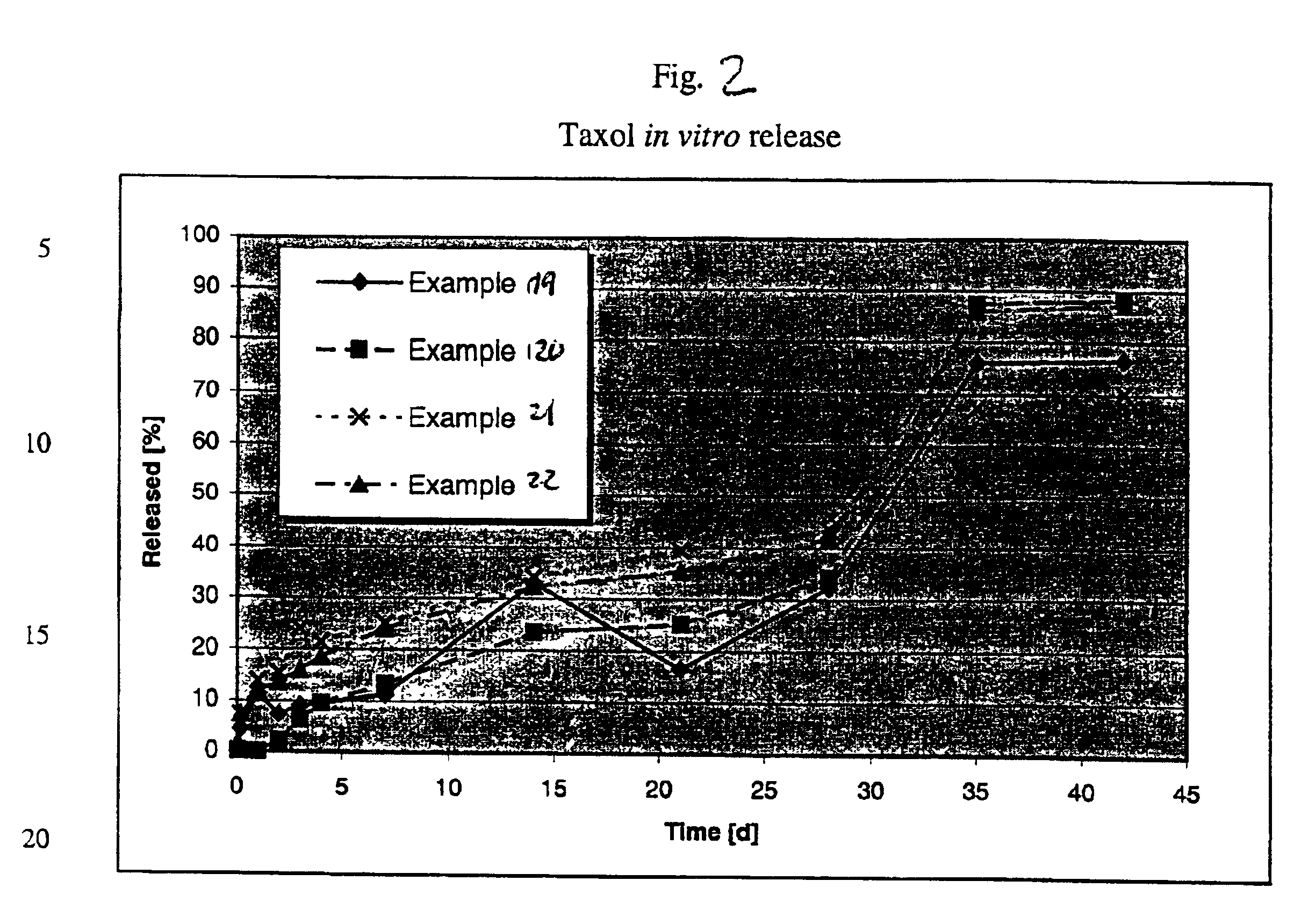

Examples

example 1

Lipophilic Active Principles

[0084]750 mg of the polymer Resomer® RG-756 is dissolved in 15 mL ethyl formate and transferred to a double-walled steel vessel (inside height 11.0 cm, inside diameter 4 cm). 5 mL of an aqueous 50 mmol Tris(hydroxymethyl)aminomethane solution (pH 7.4) containing 20 mg Budesonide is then dispersed in the polymer solution for 4 minutes at 9,000 rpm at room temperature by means of a mechanical agitator (Dispermat FT, VMA-Getzmann GmbH, 2 cm dissolver disk).

[0085]50 mL of a 50 mmol citrate buffer solution (pH 6.0) containing 4% Pluronic F-68 is then added as continuous phase during agitation at 9,000 rpm. After a dispersal time of 30 seconds, the microparticle suspension is transferred to a 500 mL two-necked flask and agitated with a magnetic stirrer. The solvent ethyl formate is then eliminated at 20° C. by application of vacuum, by introduction of nitrogen or air or by extraction with water. After 5 hours, the suspension is washed with 5 L water or an aqueo...

example 2

[0087]750 mg of the polymer Resomer® RG-756 is dissolved, together with 20 mg Budesonide in 15 mL ethyl formate and transferred to a double-walled steel vessel (inside height 11.0 cm, inside diameter 4 cm). 5 mL of an aqueous 50 mmol

Tris(hydroxymethyl)aminomethane solution (pH 7.4) is added to the solution and dispersed in the polymer solution for 4 minutes at 9,000 rpm by means of a mechanical agitator (Dispermat FT, VMA-Getzmann GmbH, 2 cm dissolver disk).

[0088]50 mL of an aqueous citrate buffer solution (50 mmol and pH 6.0) container Pluronic F-68 is added to the formed dispersion during agitation (9,000 rpm). After a disposal time of 30 seconds, the microparticle suspension is transferred to a 500 mL two-necked flask and processed further as in Example 1.

[0089]The lyophilizate, resuspended with water or an aqueous solution, contains microcapsules with an active principle content of 2.2%. The microcapsules have a diameter from 0.2 to 20 μm with the active agent budesonide embedde...

example 3

[0090]750 mg of the polymer Resomer® RG-756 is dissolved in 15 mL ethyl formate and transferred to a double-walled steel vessel (inside height 11.0 cm, inside diameter 4 cm). 5 mL of an aqueous suspension of 20 mg Taxol and a 50 mmol

Tris(hydroxymethyl)aminomethane solution (pH 7.4) is then dispersed in the polymer solution for 4 minutes at 9,000 rpm at room temperature by means of a mechanical agitator (Dispermat FT, VMA-Getzmann GmbH, 2 cm dissolver disk).

[0091]50 mL of an aqueous citrate buffer solution (50 mmol and pH 6.0) containing 4% Pluronic F-68 is then added to the formed dispersion during agitation (9,000 rpm). After a dispersal time of 30 seconds, the microparticle suspension is transferred to a 500 mL two-necked flask and agitated with a magnetic stirrer. The solvent ethyl formate is then eliminated at 20° C. by application of vacuum, by introduction of nitrogen or air or by extraction with water. After 5 hours, the suspension is washed with 5 L water or an aqueous solut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Solubility (mass) | aaaaa | aaaaa |

| Water solubility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com