Glass fiber surface chemical plating Ni-Co-Pr-B quarternary alloy plating solution and preparation method thereof

A technology of glass fiber and surface chemistry, which is applied in the field of electroless plating, can solve the problems of reducing the bonding force and conductivity of the plating layer, affecting the quality of the plating layer, and reducing the pH of the plating solution, etc., and achieves the advantages of easy promotion, easy operation and control, and simple preparation methods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

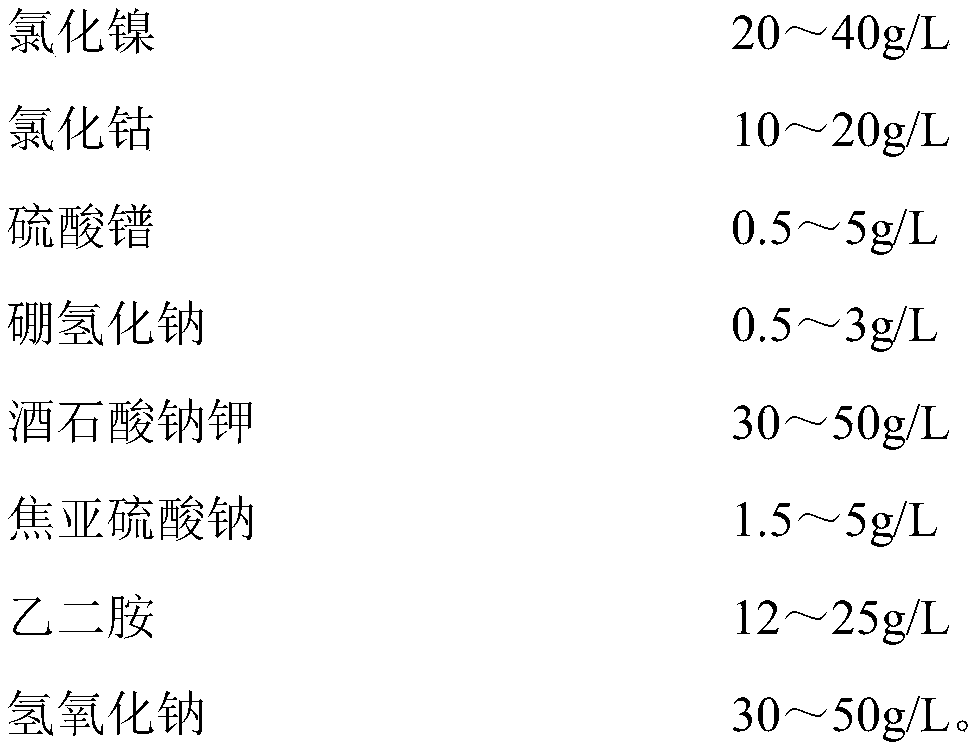

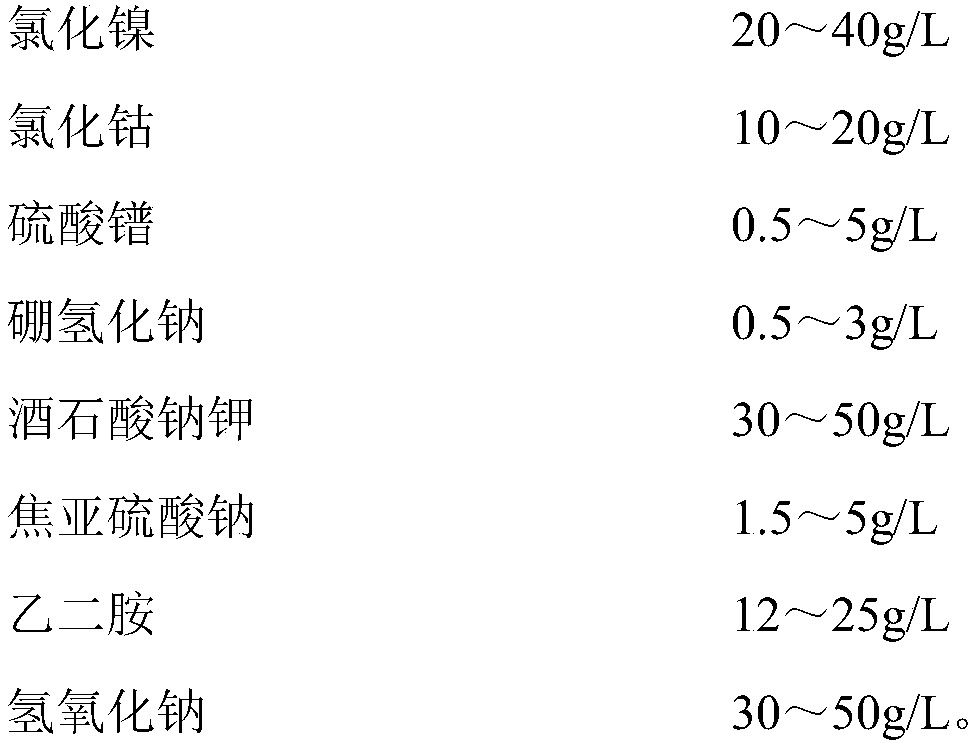

Embodiment 1

[0034] A kind of preparation method of glass fiber surface chemical plating Ni-Co-Pr-B quaternary alloy plating solution, take glass fiber as base material, soak after 24 hours with 1% sodium carbonate aqueous solution, and wash with distilled water, immersion concentration is Immerse in 1.2% silane coupling agent solution for 10 minutes, filter, dry, immerse in 50% nitric acid solution at 60°C for roughing treatment for 30 minutes, wash with water, immerse at a concentration of 10g / LSnCl 2 2H 2 O and 20g / L HCl mixed solution for sensitization treatment, immersion concentration is 0.3g / L PdCl 2 and 1.5mL / L HCl mixed solution for activation treatment. Then immerse in the 55°C plating solution for 300 minutes, the plating solution formula is nickel chloride 35g / L, cobalt chloride 18g / L, praseodymium sulfate 1g / L, sodium borohydride 1.5g / L, sodium potassium tartrate 40g / L , Ethylenediamine 18g / L, sodium hydroxide 45g / L, pH value 12.5. The electroless Ni-Co-Pr-B glass fiber was...

Embodiment 2

[0036] A kind of preparation method of glass fiber surface chemical plating Ni-Co-Pr-B quaternary alloy plating solution, take glass fiber as base material, after soaking for 12 hours with 1.5% sodium carbonate aqueous solution, and wash with distilled water, immersion concentration is Immerse in 1.2% silane coupling agent solution for 10 minutes, filter, dry, immerse in 50% nitric acid solution at 60°C for roughing treatment for 30 minutes, wash with water, immerse in 10g / L SnCl 2 2H 2 O and 20g / L HCl mixed solution for sensitization treatment, immersion concentration is 0.3g / L PdCl 2 and 1.5mL / L HCl mixed solution for activation treatment. Then immerse in the 60 ℃ plating bath and apply plating for 150 minutes. L, ethylenediamine 25g / L, sodium hydroxide 50g / L, pH 13. The electroless Ni-Co-Pr-B glass fiber was obtained on the surface. After drying it at 100°C, it was observed with a microscope that the coating was dense.

Embodiment 3

[0038]A kind of preparation method of glass fiber surface chemical plating Ni-Co-Pr-B quaternary alloy plating solution, take glass fiber as base material, soak after 24 hours with 1% sodium carbonate aqueous solution, and wash with distilled water, immersion concentration is Immerse in 1.2% silane coupling agent solution for 10 minutes, filter, dry, immerse in 50% nitric acid solution at 60°C for roughing treatment for 30 minutes, wash with water, immerse at a concentration of 10g / LSnCl 2 2H 2 O and 20g / L HCl mixed solution for sensitization treatment, immersion concentration is 0.3g / L PdCl 2 and 1.5mL / L HCl mixed solution for activation treatment. Then immerse in the 70 ℃ plating bath and apply plating for 120 minutes. L, ethylenediamine 30g / L, sodium hydroxide 50g / L, pH value 13.5. The surface electroless Ni-Co-Pr-B glass fiber was obtained, dried at 100°C, observed with a microscope, and the coating was compact.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com