Method capable of improving corrosion resistance of stainless steel composite plate welded through carbon steel stud welding

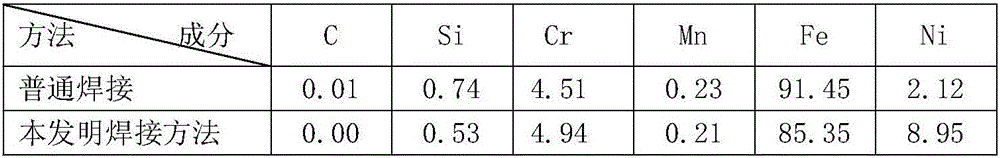

A stainless steel and composite plate technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve problems such as poor fluidity of molten pool metal, mixing, and decreased tensile strength of welded joints, so as to improve corrosion resistance and Tensile strength, precise welding position of welding studs, and the effect of improving corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

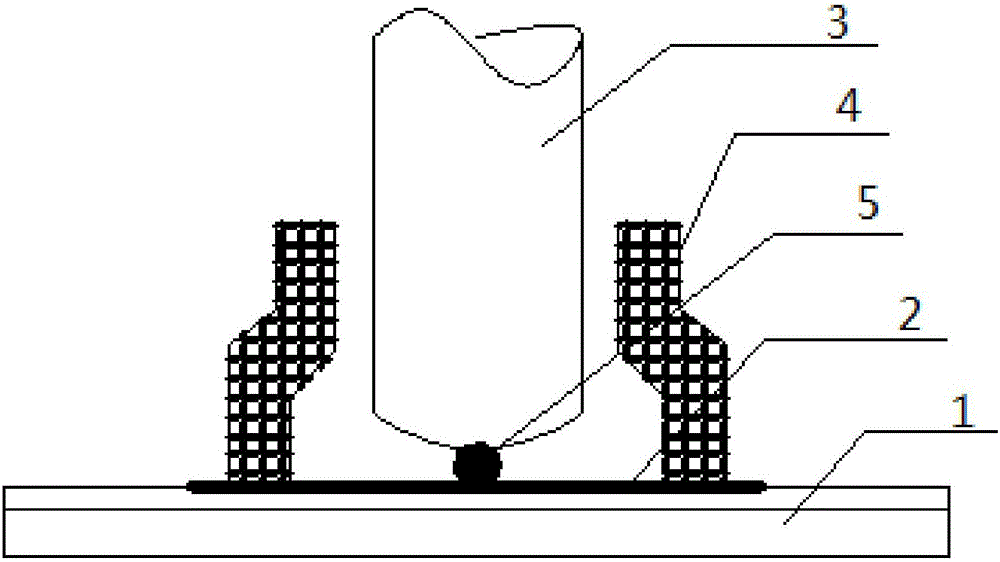

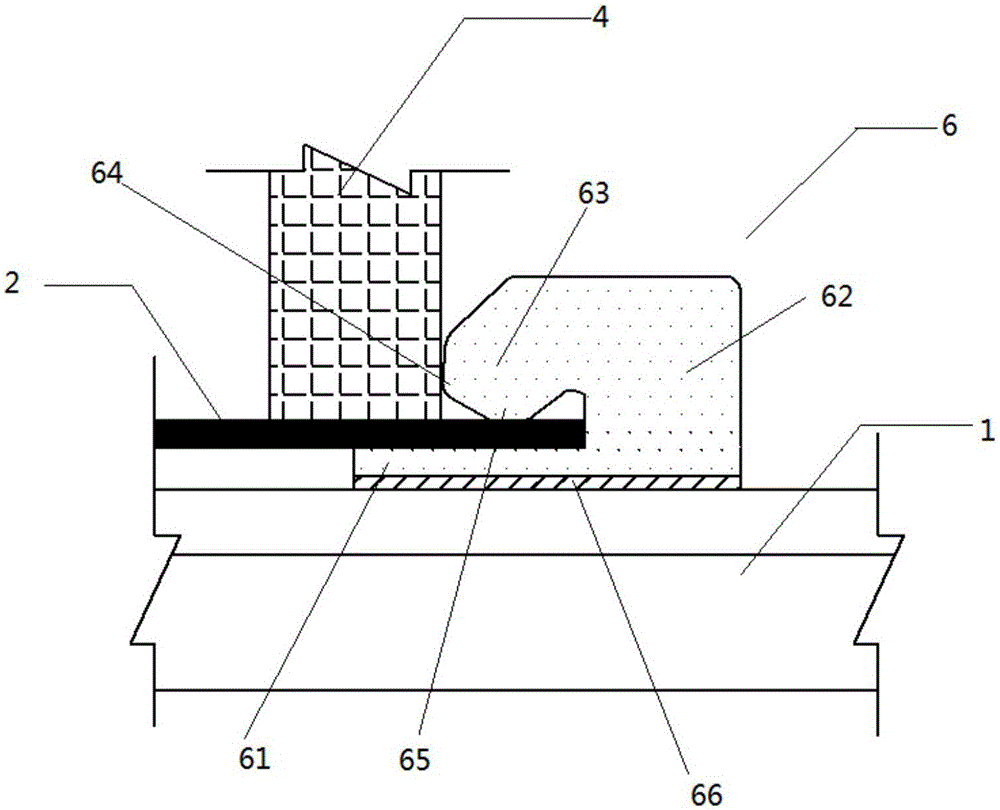

[0037] Attached below figure 1 The present invention is described in detail, a method for improving the corrosion resistance of carbon steel stud welding stainless steel clad plate, comprising the following steps:

[0038] Step 1. Place the nickel strip 2 on the base material 1 of the stainless steel clad plate. The nickel content in the nickel strip 2 is greater than 99% (percentage by weight); the thickness of the nickel strip 2 is 0.1mm to 0.3mm, and the width and length of the nickel strip 2 Both are larger than the diameter of the protective ceramic ring 4 by more than 5mm.

[0039] Step 2: Put the welding stud 3 in the clamping device of the welding torch, place the protective ceramic ring 4 of the corresponding diameter on the base material 1 of the stainless steel composite plate with the nickel strip 2, insert the welding stud 3 into the protective ceramic ring 4 and It is in contact with the nickel strip 2 laid on the base material 1 of the stainless steel clad plat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com