Molten iron desiliconizing reagent and molten iron desiliconizing method

A technology of desiliconization agent and molten iron, which is applied in the fields of desiliconization agent and desiliconization of molten iron, and can solve problems such as rising production costs and desiliconization of molten iron

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0119] Preparation of molten iron desiliconization agent

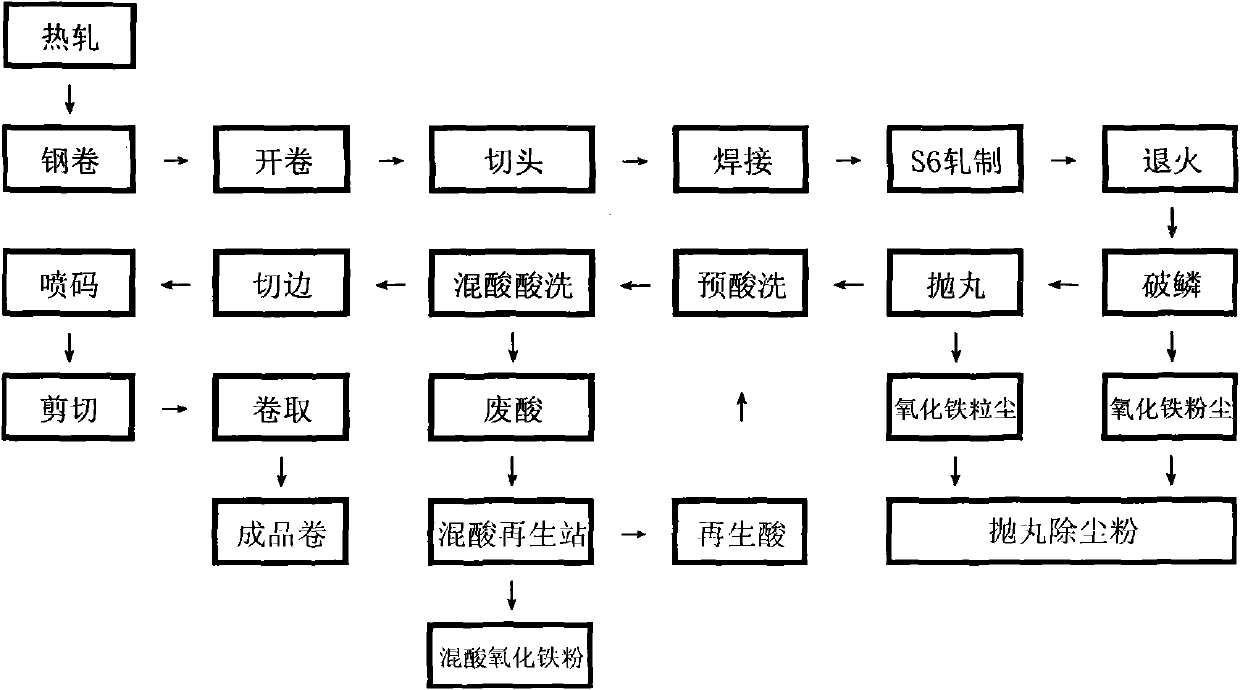

[0120] process such as Figure 11 As shown, the above-mentioned 4 kinds of materials enter the preparation stage of the desiliconization agent after the raw materials are prepared. First, they are weighed and mixed according to the ratio of the ingredients of the desiliconization agent in the column corresponding to Example 1 in Table 3, and then baked. It is best to control The water content is required to be ≤3%, and then fully mixed and stirred to form a finished desiliconization agent, which is transported by pneumatic transport tanker tanker into the tanker and transported to the molten iron desiliconization site, such as the molten iron pouring station, by pneumatic conveying. The material is sent to the desiliconization silo for desiliconization of molten iron.

[0121] The quality of the finished product silicon removal agent is controlled as follows:

[0122] 1) After processing, the moisture content of the ...

Embodiment 2

[0128] Preparation of molten iron desiliconization agent

[0129] process such as Figure 11 As shown, weigh according to the proportions of the raw materials of the desiliconizing agent in the column corresponding to Example 2 in Table 3, and adopt the same method as in Example 1 to prepare the molten iron desiliconizing agent of the present invention.

[0130] Further, the physical and chemical indicators of the molten iron desiliconization agent in Example 2 of the present invention were detected, and the specific data are shown in Table 4.

Embodiment 3

[0132] Preparation of molten iron desiliconization agent

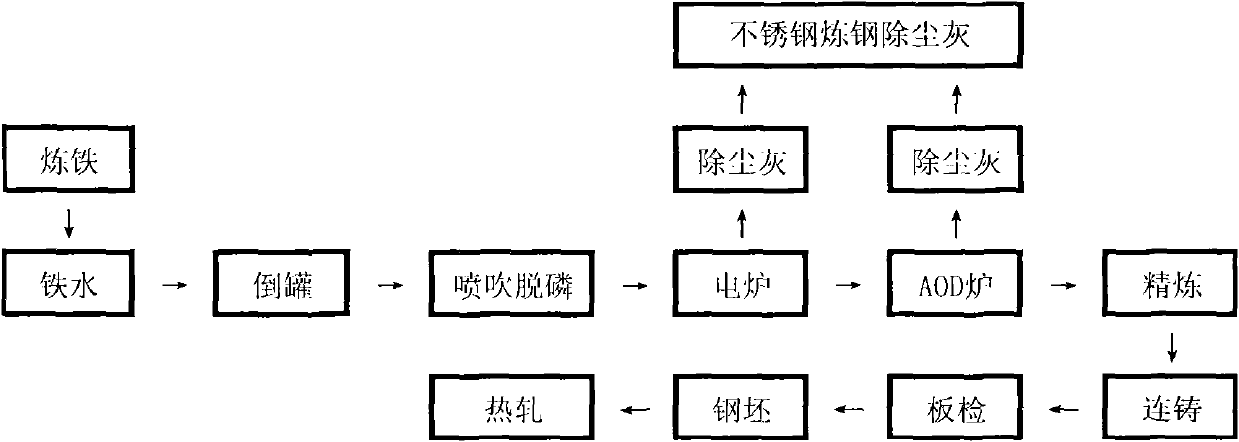

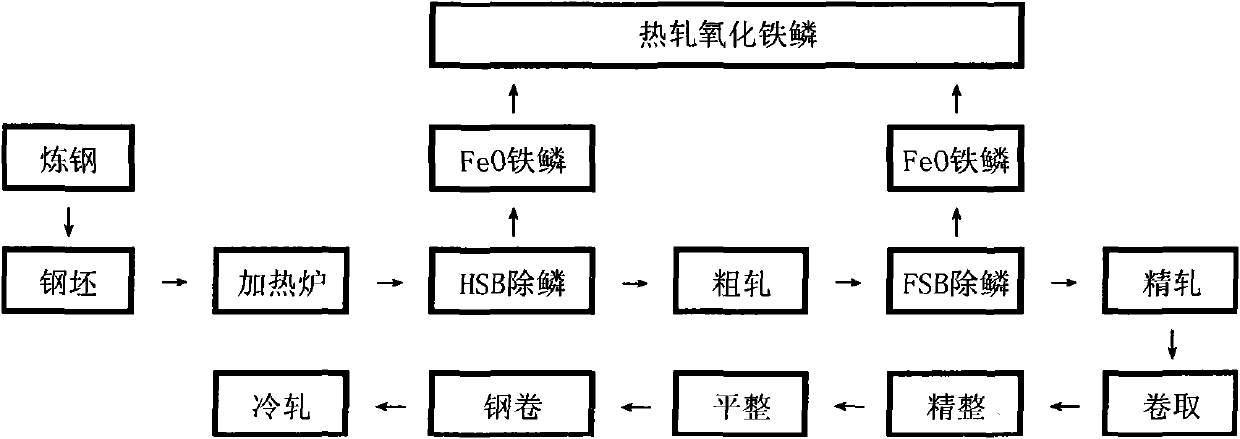

[0133] With the four solid wastes of collected mixed acid iron oxide powder, shot blasting dust removal powder, stainless steel steelmaking dust removal dust and hot-rolled iron oxide scale, dry the moisture, and take by weighing the corresponding proportion in the corresponding column of Example 3 in Table 3 The above four solid wastes are mechanically crushed, stirred and mixed evenly, and dried to obtain the molten iron desiliconization agent of the present invention.

[0134] Further, the physical and chemical indicators of the molten iron desiliconization agent in Example 3 of the present invention were detected, and the specific data are shown in Table 4.

[0135] Table 3: Ratio of finished products of molten iron desiliconization agent

[0136]

mixed acid

Iron oxide powder

shot blasting

Dust removal powder

Stainless steel

Steelmaking dust

Iron oxide scale ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com