Method and system for carrying out electrocatalytic oxidation treatment on chemical nickel wastewater

An electrocatalytic oxidation and treatment system technology, which is applied in the field of electrocatalytic oxidation treatment of chemical nickel wastewater, can solve the problems of high cost, rising prices of chemical raw materials, strong dependence on chemicals, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

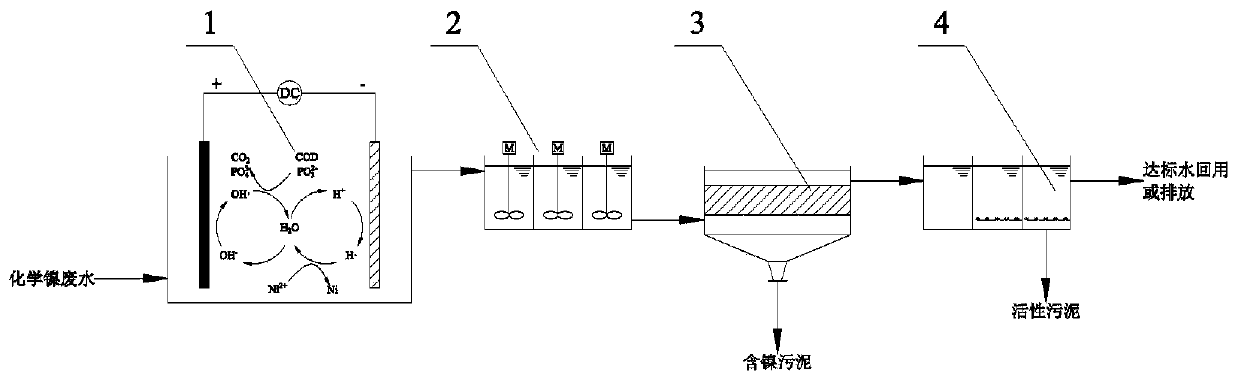

[0093] Such as figure 1 , 2 , Shown in 3, a kind of electrocatalytic oxidation treatment method of chemical nickel waste water, concrete steps are:

[0094] 1) Transport nickel-containing wastewater to the electrocatalytic oxidation reactor 1;

[0095] 2) In the electrocatalytic oxidation reactor 1, the nickel-containing wastewater is electrocatalytically oxidized;

[0096] 3) enter in the coagulation reaction box 2, carry out neutralization reaction;

[0097] 4) enter in clarifier 3, clarify;

[0098] 5) Enter the biochemical treatment device 4 for biochemical treatment.

[0099] In order to further explain this embodiment, it needs to be said that,

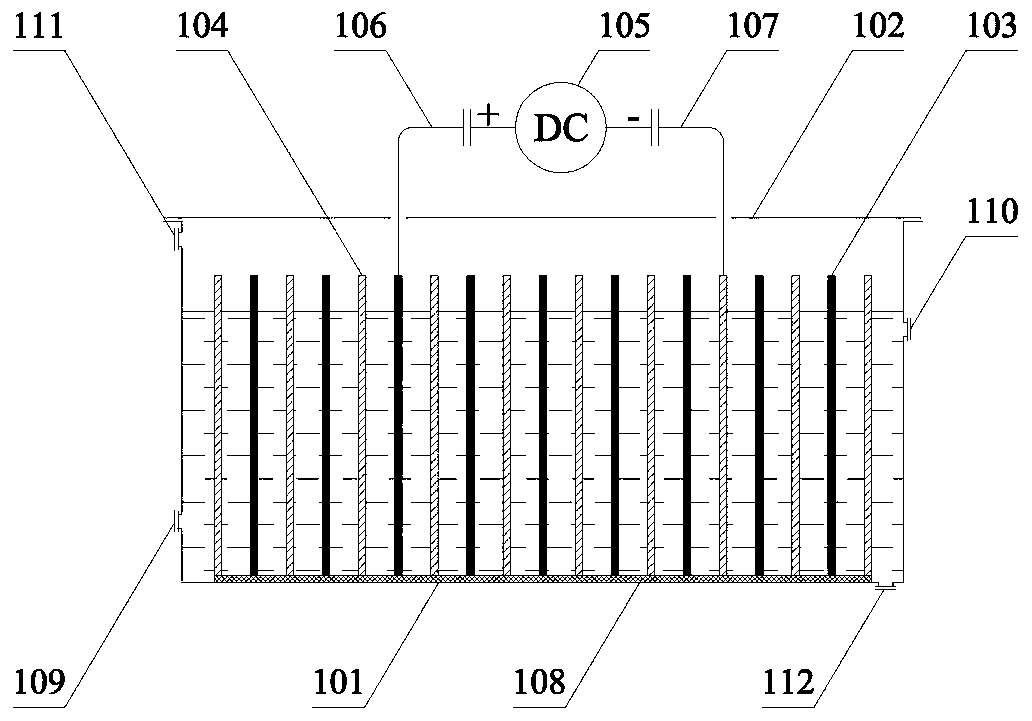

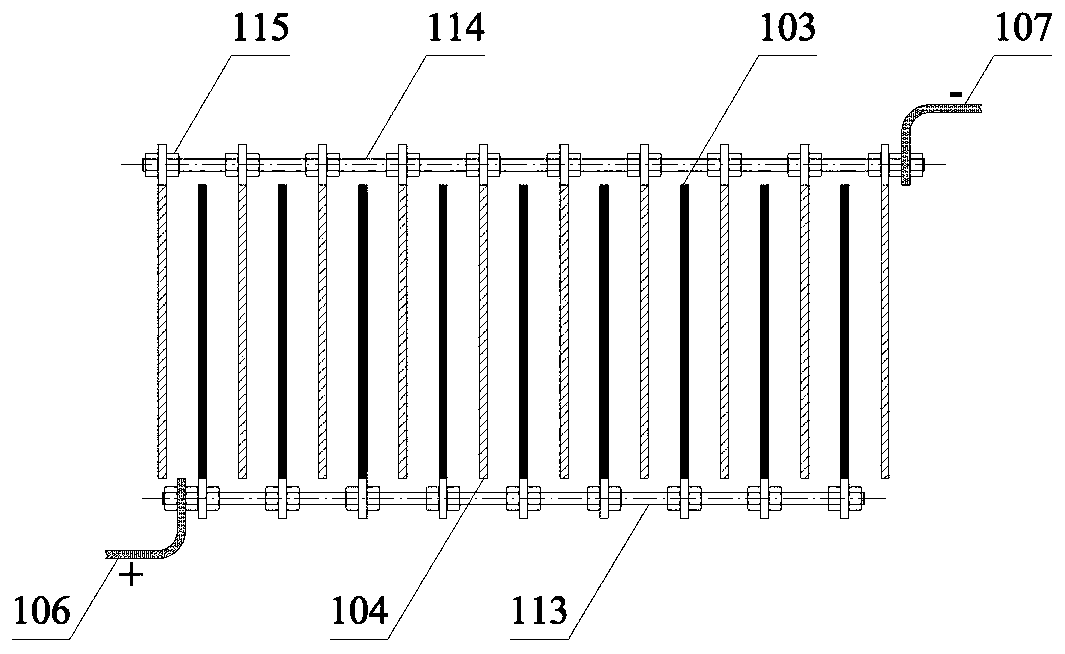

[0100] In step 1), nickel-containing wastewater enters the electrocatalytic oxidation reactor 1 from the water inlet 109;

[0101] In step 2), the nickel-containing wastewater is subjected to electrocatalytic oxidation under the action of the anode 103 and the cathode 104, and the electrolyzed wastewater flows out from the...

Embodiment 2

[0134] Such as figure 1 , 2 , 3, a chemical nickel wastewater electrocatalytic oxidation treatment system, comprising: electrocatalytic oxidation reactor 1, coagulation reaction box 2, clarifier 3, biochemical treatment device 4;

[0135] The electrocatalytic oxidation reactor 1 is connected to the coagulation reaction box 2, and is used for electrocatalytic oxidation of nickel-containing wastewater;

[0136] The coagulation reaction box 2 is connected with the clarifier 3, and is used for converting free nickel into nickel hydroxide precipitation by inputting lime milk or liquid caustic soda, coagulant and coagulant aid;

[0137] The clarifier 3 is connected with the biochemical treatment device 4, and is used to obtain clear water through clarification;

[0138] The biochemical treatment device 4 is used to treat the clarified water through microorganisms to obtain standard water.

[0139] A further improvement of the present invention is that,

[0140] The electrocataly...

Embodiment 3

[0159] Such as figure 1 , 2 , shown in 3, a kind of electrocatalytic oxidation treatment method of chemical nickel waste water, chemical nickel waste water is the waste water of chemical nickel plating process production line, total nickel concentration is 400mg / L, pH is between 8~9, COD is about 1000mg / L, conductivity The rate is about 20000μS / cm. The chemical nickel wastewater is transported to the electrocatalytic oxidation reactor 1 by pumping. The electrocatalytic oxidation reactor 1 is arranged in two stages. Catalytic oxidation reaction, the waste water enters the second-stage reactor after completing the initial "complexation breaking" in the first-stage reactor, and the total nickel concentration in the effluent is 200mg / L, and all nickel is transformed from a complexed state It is in a free state and flows out from the water outlet 110.

[0160] The waste water flowing out from the water outlet 110 is buffered by the buffer tank, and then pumped to the coagulation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com