Pyrrhotite flotation depressant and application thereof

A pyrrhotite and inhibitor technology, applied in flotation, solid separation and other directions, can solve the problem that the grade of nickel concentrate is not greatly improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

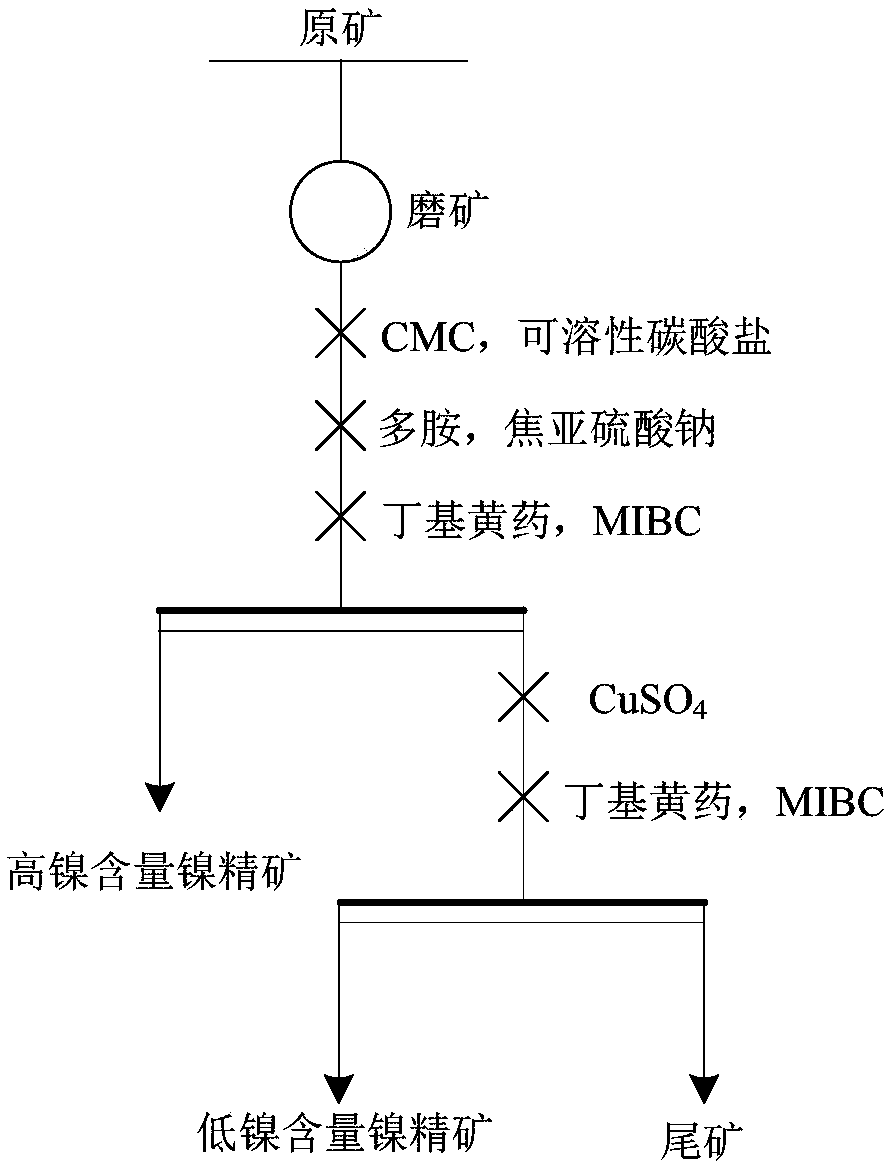

Method used

Image

Examples

Embodiment 1

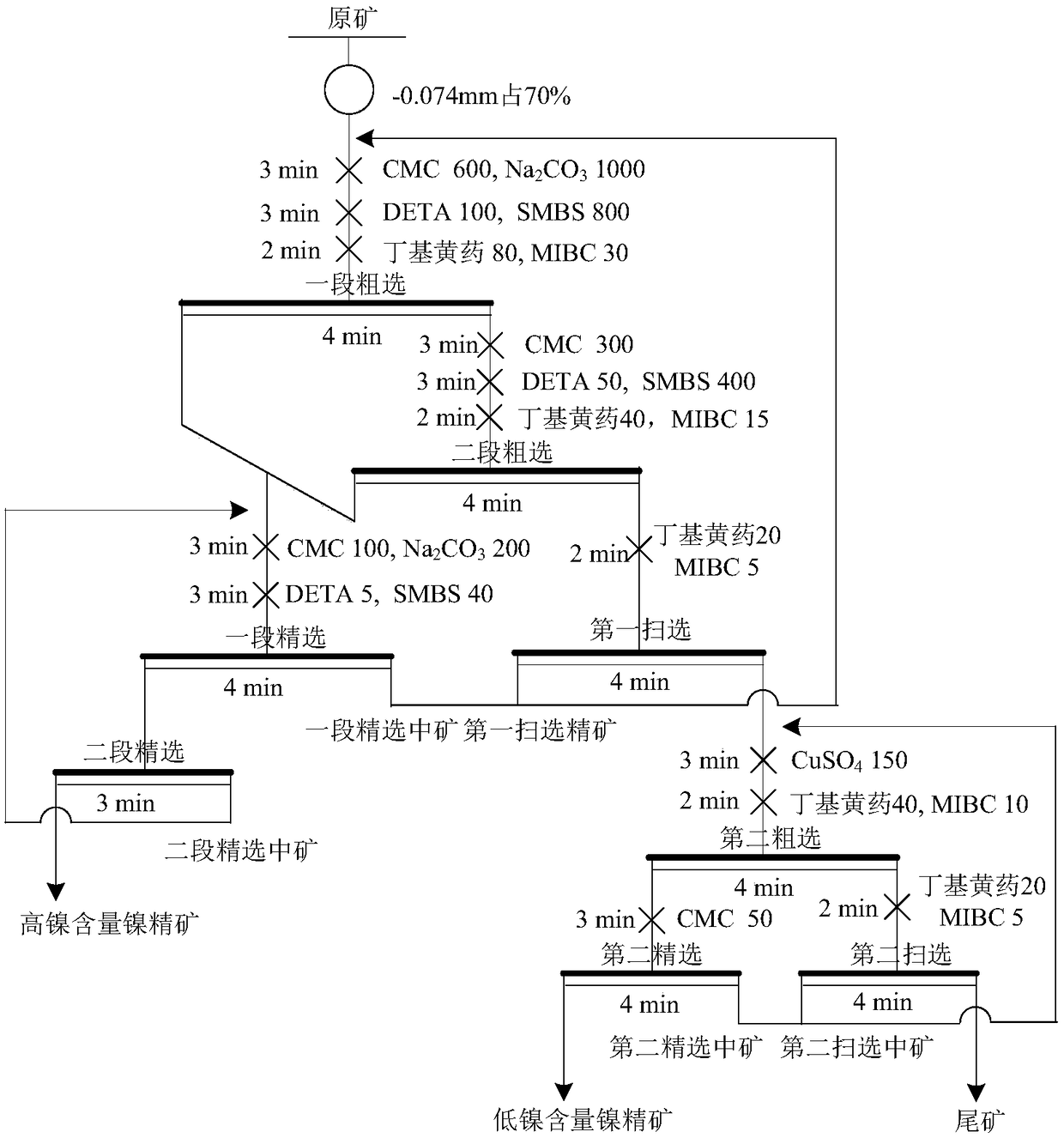

[0035] Such as figure 2 As shown, add 600g CMC, 1000g Na 2 CO 3 Act for 3 minutes; add 100g DETA, 800g SMBS to act for 3 minutes; add 80g butyl xanthate, 30g MIBC to act for 2 minutes, and then conduct a roughing flotation for 4 minutes. A section of rough separation concentrate and a section of rough separation ore are obtained.

[0036] Then, the first-stage rougher ore is subjected to second-stage rougher flotation. Add 300g of CMC to the first stage of rough separation for 3 minutes based on the amount of dry ore per ton; add 50g of DETA and 400g of SMBS for 3 minutes; add 40g of butyl xanthate and 15g of MIBC for 2 minutes and then carry out the second stage of rough separation and flotation for 4 minutes. The second-stage rougher concentrate and the second-stage rougher ore are obtained.

[0037] Subsequently, the first-stage rougher concentrate and the second-stage rougher concentrate are subjected to the first-stage selection flotation; the second-stage rougher co...

Embodiment 2

[0043] Add 500g CMC, 1500g Na 2 CO 3 Act for 3 minutes; add 150g DETA, 1000g SMBS for 3 minutes; add 60g butyl xanthate, 30g MIBC for 2 minutes, and then conduct a roughing flotation for 4 minutes. A section of rough separation concentrate and a section of rough separation ore are obtained.

[0044] Then, the first-stage rougher ore is subjected to second-stage rougher flotation. Add 250g CMC per ton of dry ore to the first-stage rough separation for 3 minutes; add 70g DETA and 500g SMBS for 3 minutes; add 30g butyl xanthate and 15g MIBC for 2 minutes, then conduct second-stage rough separation and flotation for 4 minutes. The second-stage rougher concentrate and the second-stage rougher ore are obtained.

[0045] Subsequently, the first-stage rougher concentrate and the second-stage rougher concentrate are subjected to the first-stage selection flotation; the second-stage rougher concentrate is subjected to the first scavenging flotation. Add 80g CMC, 300g Na 2 CO 3 Act...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com