Multi-layer aluminum-doped nickel-cobalt-manganese precursor and preparation method thereof

A precursor, nickel-cobalt-manganese technology, applied in chemical instruments and methods, nickel compounds, inorganic chemistry, etc., can solve the problems of not providing effective capacity, hindering lithium ion deintercalation, etc., to improve thermal stability and structural stability , Improve thermal stability and structural stability, and reduce the effect of structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

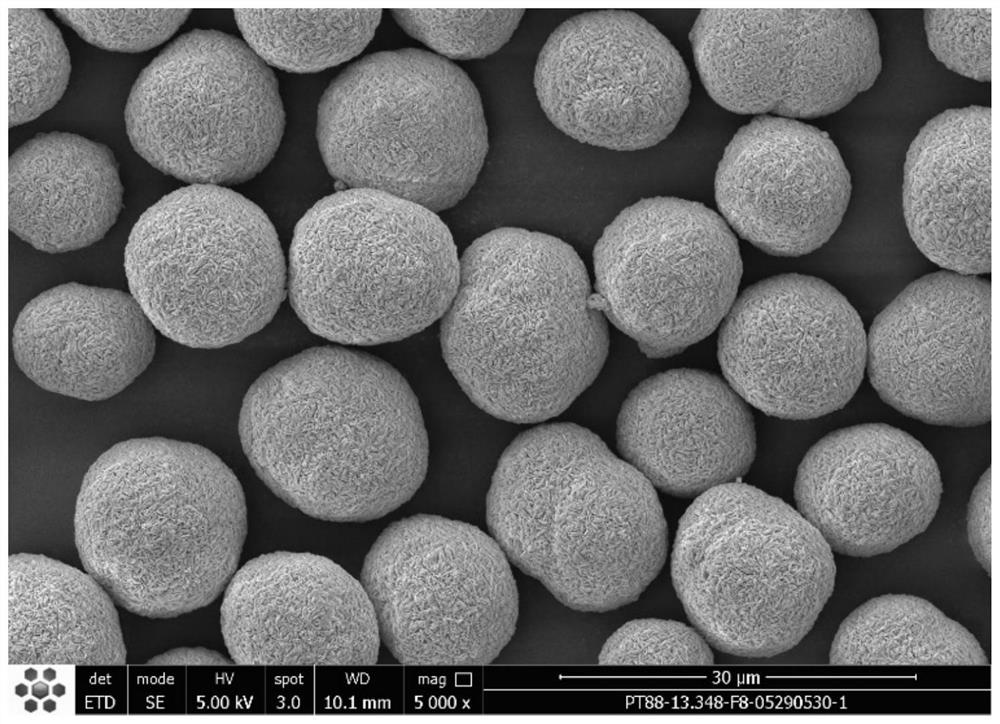

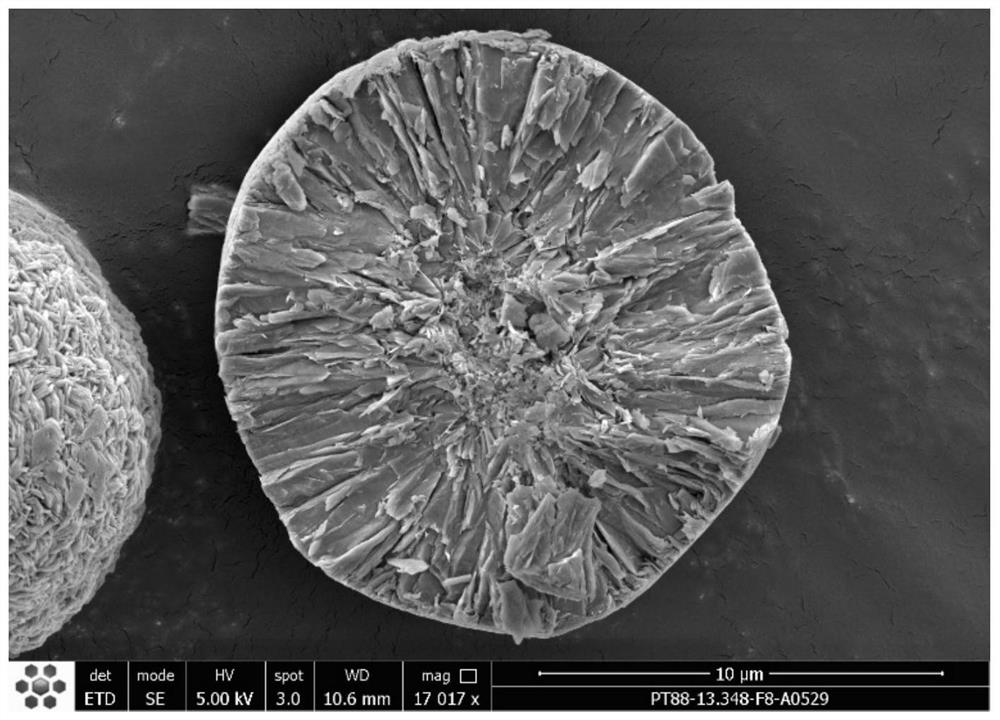

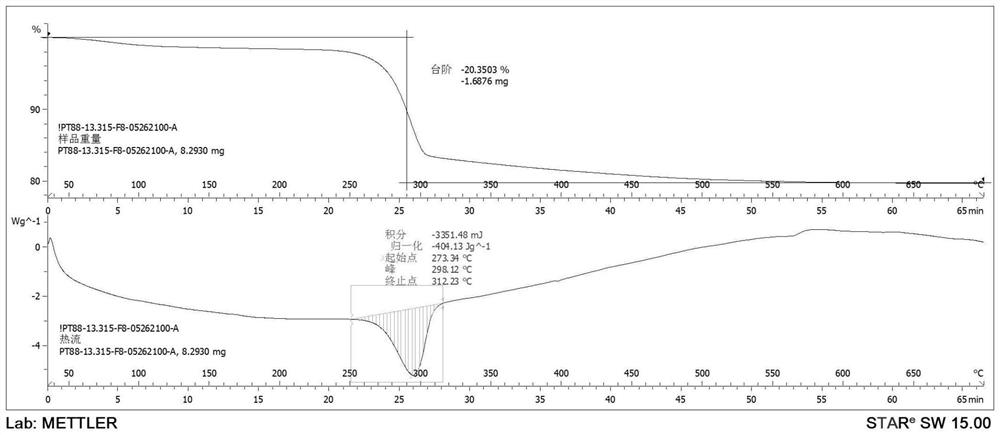

[0045] A multilayer aluminum-doped nickel-cobalt-manganese precursor, starting with undoped nickel-cobalt-manganese hydroxide Ni 0.885 co 0.09 mn 0.025 (OH) 2 It is the inner core, the D50 of the inner core is about 4.5 μm, and the surface of the inner core is successively covered with the first aluminum-doped nickel-cobalt-manganese hydroxide layer Ni with a thickness of about 1.5 μm. 0.867 co 0.088 mn 0.025 al 0.002 (OH) 2 , the first undoped nickel-cobalt-manganese hydroxide layer Ni with a thickness of about 2 μm 0.885 co 0.09 mn 0.025 (OH) 2 , the second aluminum-doped nickel-cobalt-manganese hydroxide layer Ni with a thickness of about 2 μm 0.867 co 0.088 mn 0.025 al 0.002 (OH) 2 , a second undoped nickel-cobalt-manganese hydroxide layer Ni with a thickness of about 2 μm 0.885 co 0.09 mn 0.025 (OH) 2 And the outermost layer with a thickness of about 1.5 μm, that is, the third aluminum-doped nickel-cobalt-manganese hydroxide layer Ni 0.867 co 0.088 mn ...

Embodiment 2

[0063] A multilayer aluminum-doped nickel-cobalt-manganese precursor, starting with undoped nickel-cobalt-manganese hydroxide Ni 0.885 co 0.09 mn 0.025 (OH) 2 It is the inner core, the D50 of the inner core is about 4.5 μm, and the surface of the inner core is successively covered with the first aluminum-doped nickel-cobalt-manganese hydroxide layer Ni with a thickness of about 3.5 μm. 0.867 co 0.088 mn 0.025 al 0.002 (OH) 2 , the first undoped nickel-cobalt-manganese hydroxide layer Ni with a thickness of about 3 μm 0.885 co 0.09 mn 0.025 (OH) 2 , the second aluminum-doped nickel-cobalt-manganese hydroxide layer Ni with a thickness of about 2.5 μm 0.867 co 0.088 mn 0.025 al 0.002 (OH) 2 The secondary particle size D10 of the nickel-cobalt-manganese precursor doped with multilayer aluminum is 8.67 μm, the particle size D50 is 13.73 μm, the particle size D90 is 17.41 μm, the particle size distribution (D90-D10) / D50 is 0.64, and the tap density 2.04g / cm 3 , the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com