Titanium oxide supported ferric vanadate catalyst, as well as preparation method and use thereof

A catalyst and supported technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problem of low thermal stability of catalysts, inability to withstand high temperature thermal shock, etc. problems, to achieve excellent anti-H2O and anti-SO2 poisoning performance, low-temperature activity improvement, selectivity improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

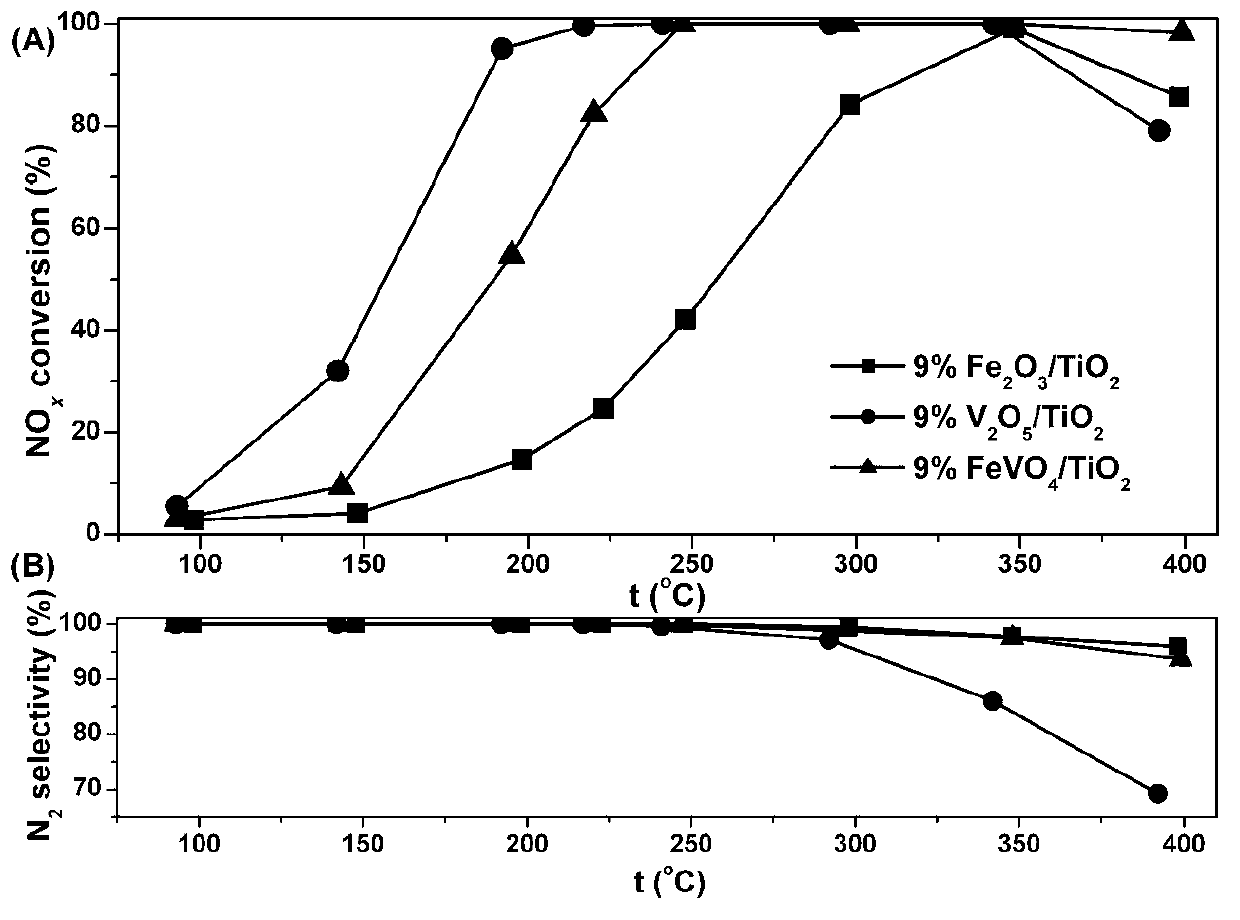

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A kind of titanium oxide supported iron vanadate catalyst, described catalyst is made of anatase type TiO 2 Carriers and loads on TiO 2 FeVO on support 4 Active component composition, based on the mass of the catalyst as 100wt%, FeVO 4 The mass percentage of is 9wt%.

[0037] The preparation method of described catalyst is:

[0038] (1) In the presence of oxalic acid, prepare a mixed solution of ferric nitrate and ammonium metavanadate, the molar ratio of the iron element in the ferric nitrate to the vanadium element in the ammonium metavanadate is 1:1;

[0039] (2) Add anatase TiO to the mixed solution obtained in step (1) 2 The carrier is impregnated, dried at 120° C. for 12 hours, and calcined at 400° C. for 6 hours to obtain a titanium oxide-supported iron vanadate catalyst.

Embodiment 2

[0041] A kind of titanium oxide supported iron vanadate catalyst, described catalyst is made of anatase type TiO 2 Carriers and loads on TiO 2 FeVO on support 4 Active component composition, based on the mass of the catalyst as 100wt%, FeVO 4 The mass percentage is 1.5wt%.

[0042] The preparation method of described catalyst is:

[0043] (1) In the presence of oxalic acid, prepare a mixed solution of ferric nitrate and ammonium metavanadate, the molar ratio of the iron element in the ferric nitrate to the vanadium element in the ammonium metavanadate is 1:1;

[0044] (2) Add anatase TiO to the mixed solution obtained in step (1) 2 The carrier is impregnated, dried at 100° C. for 16 hours, and calcined at 350° C. for 10 hours to obtain a titanium oxide-supported iron vanadate catalyst.

Embodiment 3

[0046] A kind of titanium oxide supported iron vanadate catalyst, described catalyst is made of anatase type TiO 2 Carriers and loads on TiO 2 FeVO on support 4 Active component composition, based on the mass of the catalyst as 100wt%, FeVO 4 The mass percentage is 15wt%.

[0047] The preparation method of described catalyst is:

[0048] (1) In the presence of oxalic acid, prepare a mixed solution of ferric nitrate and ammonium metavanadate, the molar ratio of the iron element in the ferric nitrate to the vanadium element in the ammonium metavanadate is 1:1;

[0049] (2) Add anatase TiO to the mixed solution obtained in step (1) 2 The carrier is impregnated, dried at 140°C for 8 hours, and calcined at 450°C for 4 hours to obtain a titanium oxide-supported iron vanadate catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com