Modified Cu-SSZ-13 molecular sieves as well as preparation method and application thereof

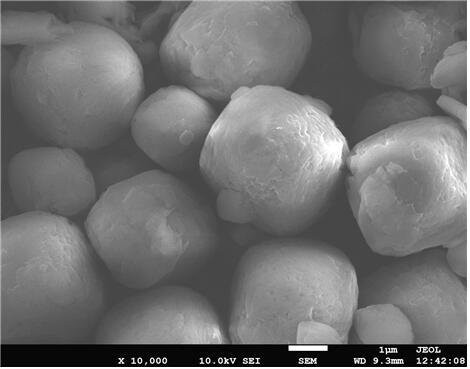

A cu-ssz-13, molecular sieve technology, applied in the field of molecular sieves, can solve the problem of low SCR activity, reduce the generation of by-products, avoid secondary pollution, and achieve the effect of high crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The invention provides a kind of preparation method of modified Cu-SSZ-13 molecular sieve, comprising the following steps:

[0042] 1) Mix aluminum source, alkali metal hydroxide, templating agent, silicon source and water to obtain initial sol;

[0043] 2) Calcining the initial sol after hydrothermal crystallization to obtain M-SSZ-13 molecular sieve, and the M is an alkali metal;

[0044] 3) Carrying out the ion exchange reaction between the M-SSZ-13 molecular sieve and the ammonium salt, and then roasting to obtain the H-SSZ-13 molecular sieve;

[0045] 4) The H-SSZ-13 molecular sieve is subjected to ion exchange reaction with divalent copper salt and then calcined to obtain a modified Cu-SSZ-13 molecular sieve.

[0046] The invention mixes aluminum source, alkali metal hydroxide, template agent, silicon source and water to obtain initial sol. In the present invention, the aluminum source is preferably one or more of aluminum sulfate, aluminum nitrate, aluminum hyd...

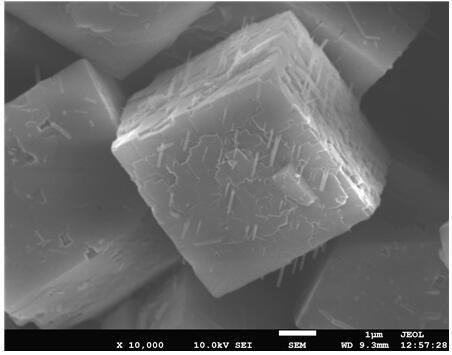

Embodiment 1

[0065] 1) Dissolve 0.432g lithium hydroxide in 44ml deionized water, then add 1.998g aluminum sulfate octadecahydrate to the above solution and stir for 3-5 minutes, continue to add 20.256g template agent TMAdaOH (25%) to the solution, stir After the solution was clear and transparent, 14.580g of silica sol JN25 was added as a silicon source, and the initial sol was obtained after stirring for 2 hours. At this time, the molar ratio of aluminum element, alkali metal hydroxide, template agent, silicon element in the silicon source and water is 0.1:0.3:0.4:1:66.

[0066] 2) The obtained initial sol was transferred to a polytetrafluoroethylene-lined stainless steel reactor and crystallized at 150 °C for 6 days. After the reaction is completed, cool to room temperature, filter, fully wash with deionized water and dry, and then bake at 550° C. for 6 hours to remove the template agent to obtain Li-SSZ-13 molecular sieve.

[0067] 3) Take 2g of the above-mentioned Li-SSZ-13 molecular...

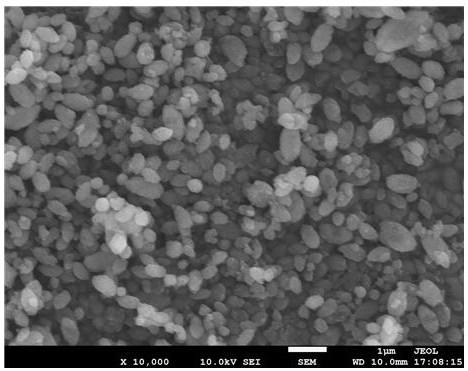

Embodiment 2

[0072] 1) Dissolve 0.722g of sodium hydroxide in 44ml of deionized water, then add 0.246g of sodium metaaluminate into the above solution and stir for 3-5 minutes. Continue to add 20.281g template agent TMAdaOH (25%) to the solution, stir until the solution is clear and transparent, add 14.838g silica sol as a silicon source, and continue stirring for 2h to obtain the initial sol. At this time, the molar ratio of aluminum element, alkali metal hydroxide, template agent, silicon element in the silicon source and water is 0.1:0.3:0.4:1:66.

[0073] 2) The obtained initial sol was transferred to a polytetrafluoroethylene-lined stainless steel reactor for crystallization at 150 °C for 6 days. After the reaction is completed, cool to room temperature, filter, fully wash with deionized water and dry, and then bake at 550° C. for 6 hours to remove the template agent to obtain Na-SSZ-13 molecular sieve.

[0074] 3) Take 2g of the above-mentioned Na-SSZ-13 molecular sieve and add it t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com