Arrangement for Reducing Nitrogen Oxides in Exhaust Gases

a technology of nitrogen oxides and exhaust gases, which is applied in the direction of exhaust treatment, combination devices, ion implantation coatings, etc., can solve the problems of not being able to complete the nhsub>3/sub>-oxidation catalyst, not having a complete nhsub>3/sub>conversion, and not having a sufficiently precise and stable exhaust gas sensor available for regulating the system, etc. , to achieve the effect of significantly accelerating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

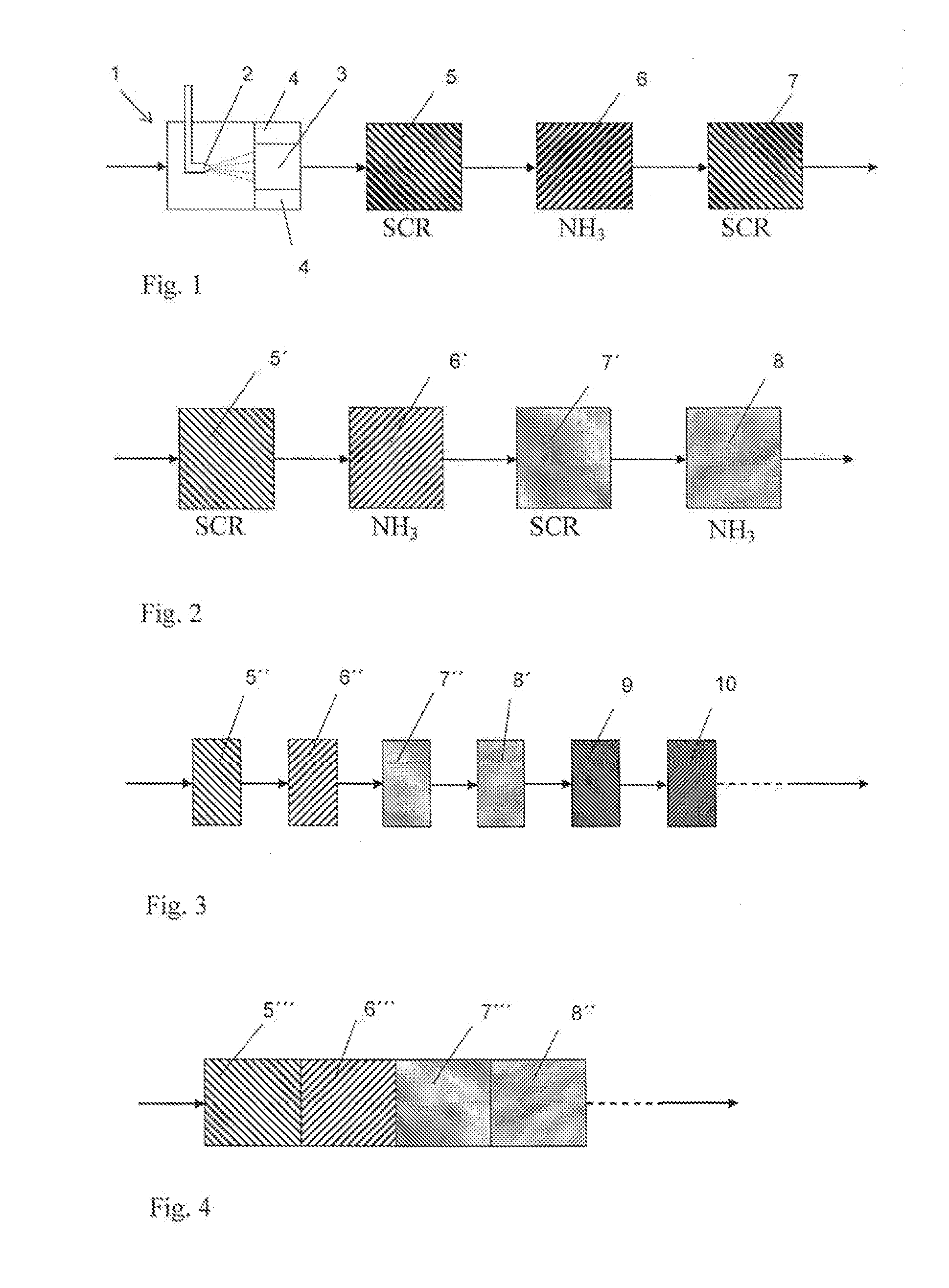

[0026]Referring now to the drawings in detail, an arrangement for the selective catalytic reduction is schematically illustrated in FIG. 1. The exhaust gases, which are produced by an internal combustion engine (not illustrated) by the combustion processes, and which are symbolized by the arrows in FIG. 1, initially pass into an exhaust gas treatment section 1, in which a reduction agent is added to the hot exhaust gas as close to the engine as possible. As is customary with motor vehicles having SCR catalysts, the reduction agent is an aqueous urea solution; it is of course also possible to add solid urea, as already described in detail in the pertinent technical literature. The dosing is effected as a function of operating parameters of the internal combustion engine, controlled by an engine control unit (not illustrated), in such a way that the aqueous urea solution is sprayed into the exhaust gas stream via a nozzle 2 directly upstream of a hydrolysis catalyst 3. The task of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com