Vanadium oxide nanotube denitration catalyst with anti-poisoning performance and preparation method of catalyst

A denitration catalyst, vanadium oxide technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problem of less research on the anti-poisoning performance of denitration catalysts, etc. Achieve excellent NOx catalytic reduction performance, good water resistance and sulfur resistance, and low sulfur dioxide oxidation rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

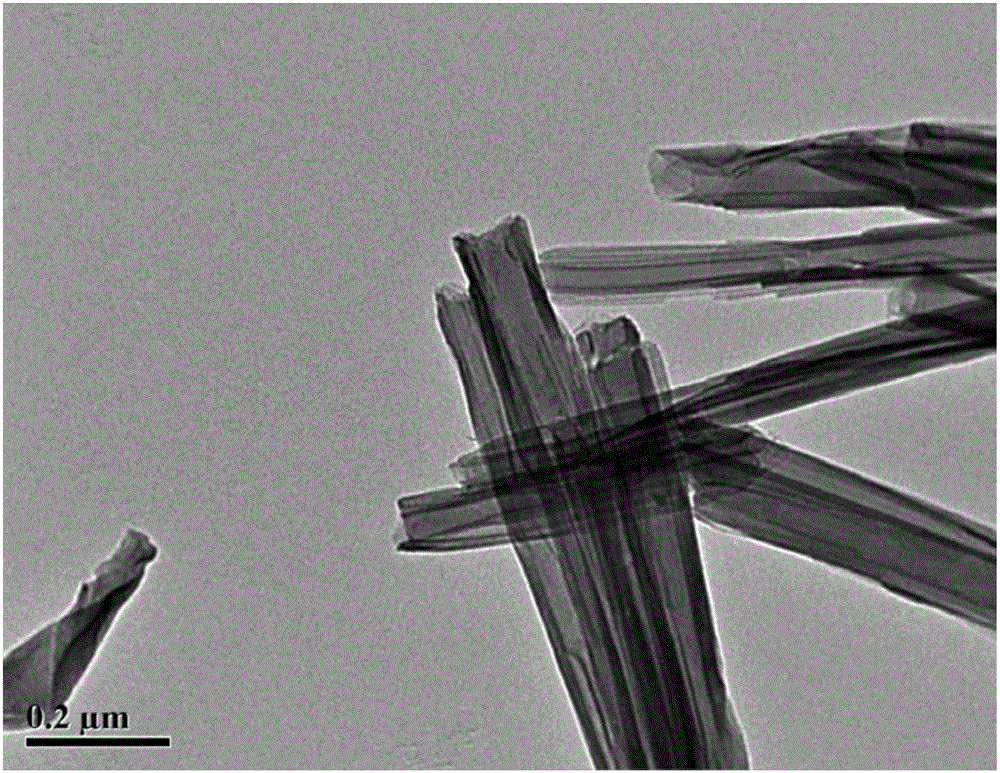

[0045] Preparation of vanadium oxide nanotubes: the molar ratio of raw materials is V 2 o 3 : absolute ethanol: water: laurylamine = 1:20:50:5. will V 2 o 3 Add it into the absolute ethanol solution together with dodecylamine, stir and dissolve for 1 hour. Then add deionized water to it, and continue to stir for 6 hours to obtain a uniformly mixed suspension; then pour it into a polytetrafluoro-lined hydrothermal kettle at 150°C for 24 hours, and the filling degree of the hydrothermal kettle is 70 %; The precipitate after the hydrothermal treatment is first transferred to the absolute ethanol solution and stirred for 6 hours to remove organic matter and impurities, then washed with water, filtered, and dried at 60°C. The surface morphology of the prepared vanadium-titanium oxide nanotubes is as follows figure 1 shown.

[0046] Catalyst preparation: Add 1 g of cerium nitrate hexahydrate and 2 g of ammonium tungstate to 100 ml of deionized water, stir and dissolve for 1 hou...

Embodiment 2

[0050] Preparation of vanadium oxide nanotubes: the molar ratio of raw materials is V 2 o 4 : absolute ethanol: water: cetylamine = 1:30:70:4. will V 2 o 4 Add hexadecylamine into anhydrous ethanol solution, stir and dissolve for 1 hour. Then add deionized water to it, and continue to stir for 6 hours to obtain a well-mixed suspension; then pour it into a polytetrafluoro-lined hydrothermal kettle for 18 hours at 180°C, and the filling degree of the hydrothermal kettle is 60 %; The precipitate after hydroheating was first transferred to absolute ethanol solution and stirred for 6 hours to remove organic matter and impurities, then washed with water, filtered, and dried at 60°C.

[0051] Catalyst preparation: Add 2 grams of niobium oxalate into 100ml of deionized water, stir and dissolve for 1 hour, then add 4g of vanadium oxide nanotubes into it and continue stirring for 6 hours, then dry at 80°C and burn at 450°C The finished catalyst product was obtained in 4 hours.

[...

Embodiment 3

[0055] Preparation of vanadium oxide nanotubes: the molar ratio of raw materials is V 2 o 5 : absolute ethanol: water: octadecylamine = 1:40:80:10. will V 2 o 5 Add octadecylamine into anhydrous ethanol solution, stir and dissolve for 1 hour. Then add deionized water to it, and continue to stir for 6 hours to obtain a uniformly mixed suspension; then pour it into a polytetrafluoro-lined hydrothermal kettle for 36 hours at 160°C, and the filling degree of the hydrothermal kettle is 70 %; The precipitate after hydroheating was first transferred to absolute ethanol solution and stirred for 8 hours to remove organic matter and impurities, then washed with water, filtered, and dried at 80°C.

[0056] Catalyst preparation: Add 1 g of ferric nitrate nonahydrate and 2 g of ammonium molybdate into 100 ml of deionized water, stir and dissolve for 1 hour, then add 4 g of vanadium oxide nanotubes into it and continue stirring for 6 hours. Dry it and burn it at 500°C for 3 hours to ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com