Preparation method and application of hydrotalcite-like NiMnFe low temperature denitration catalyst

A low-temperature denitration, hydrotalcite-based technology, applied in chemical instruments and methods, chemical elements of heterogeneous catalysts, catalysts for physical/chemical processes, etc., can solve problems such as sintering and easy agglomeration, and achieve excellent catalytic performance and thermal stability. The effect of high and excellent water and sulfur resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

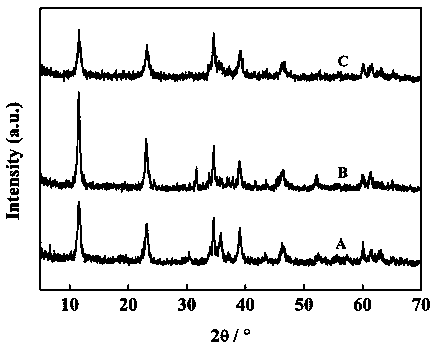

[0037] Example 1: c(Ni 2+ ):c(Mn 2+ ):c(Fe 3+ ) =2:0.5:1

[0038] (1) Weigh 11.63 g of nickel nitrate hexahydrate, 8.080 g of ferric nitrate nonahydrate, and dissolve 2.3 mL of manganese nitrate (50%) in 40 mL of distilled water, and stir with a magnetic stirrer for 10 min to completely dissolve until the solution is clear .

[0039] (2) Weigh 9.610 g of urea solid and 0.471 g of sodium citrate solid into the mixed salt solution in (1), and stir it with magnetic force to dissolve and stir evenly.

[0040] (3) Continue to stir the mixed solution obtained in (2) for 30 min with a magnetic stirrer, and measure the pH value of the mixed solution with a pH meter.

[0041] (4) Then the obtained mixed solution was sealed and placed in a polytetrafluoroethylene-lined stainless steel reactor, and hydrothermally treated in an oven at 120±2 °C for 12 h.

[0042] (5) After the reaction kettle is naturally cooled, filter the reacted solution to get the precipitate, wash it with deioni...

Embodiment 2

[0045] Example 2: c(Ni 2+ ):c(Mn 2+ ):c(Fe 3+ ) =2:1:1

[0046] (1) Weigh 8.142 g of nickel nitrate hexahydrate and 5.656 g of ferric nitrate nonahydrate, measure 3.3 mL of manganese nitrate solution (50%) and dissolve it in 40 mL of distilled water, and stir with a magnetic stirrer for 10 min to completely dissolve until the solution clarify.

[0047] (2) Weigh 0.919 g of urea solids and 0.089 g of sodium citrate solids into the mixed salt solution in (1), dissolve them with magnetic stirring and stir evenly.

[0048] (3) Continue to stir the mixed solution obtained in (2) for 30 min with a magnetic stirrer, and measure the pH value of the mixed solution with a pH meter.

[0049] (4) Then the obtained mixed solution was sealed and placed in a polytetrafluoroethylene-lined stainless steel reactor, and hydrothermally treated in an oven at 120±2 °C for 12 h.

[0050] (5) After the reaction kettle is naturally cooled, filter the reacted solution to get the precipitate, wash ...

Embodiment 3

[0053] Example 3: c(Ni 2+ ):c(Mn 2+ ):c(Fe 3+ ) =3:1:1

[0054] (1) Weigh 3.489 g of nickel nitrate hexahydrate and 1.616 g of ferric nitrate nonahydrate, measure 0.9 mL of manganese nitrate solution (50%) and dissolve in 40 mL of distilled water, and stir with a magnetic stirrer for 10 min to completely dissolve until the solution clarify.

[0055] (2) Weigh 0.092 g of urea solids and 0.005 g of sodium citrate solids into the mixed salt solution in (1), and stir them with magnetic force to dissolve and stir evenly.

[0056] (3) Continue to stir the mixed solution obtained in (2) for 30 min with a magnetic stirrer, and measure the pH value of the mixed solution with a pH meter.

[0057] (4) Then the obtained mixed solution was sealed and placed in a polytetrafluoroethylene-lined stainless steel reactor, and hydrothermally treated in an oven at 120±2 °C for 12 h.

[0058] (5) After the reaction kettle is naturally cooled, filter the reacted solution to get the precipitate,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com