Medium and low temperature denitration catalyst with protective layer and preparation method thereof

A low-temperature denitrification technology with a protective layer, which is applied in the field of air pollution control technology and environmental catalytic materials, can solve the problems of poisoning and service life, and achieve the effects of prolonging service life, improving denitrification efficiency, and strong sulfur resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

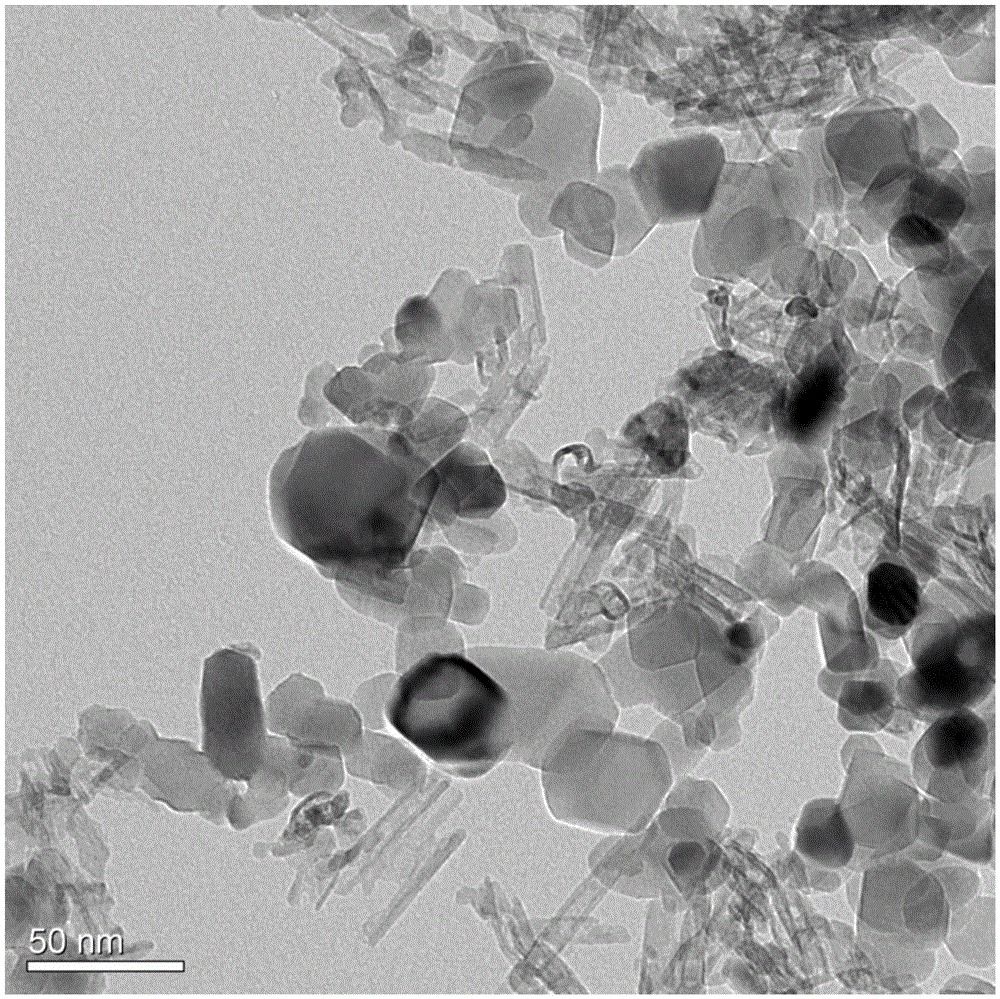

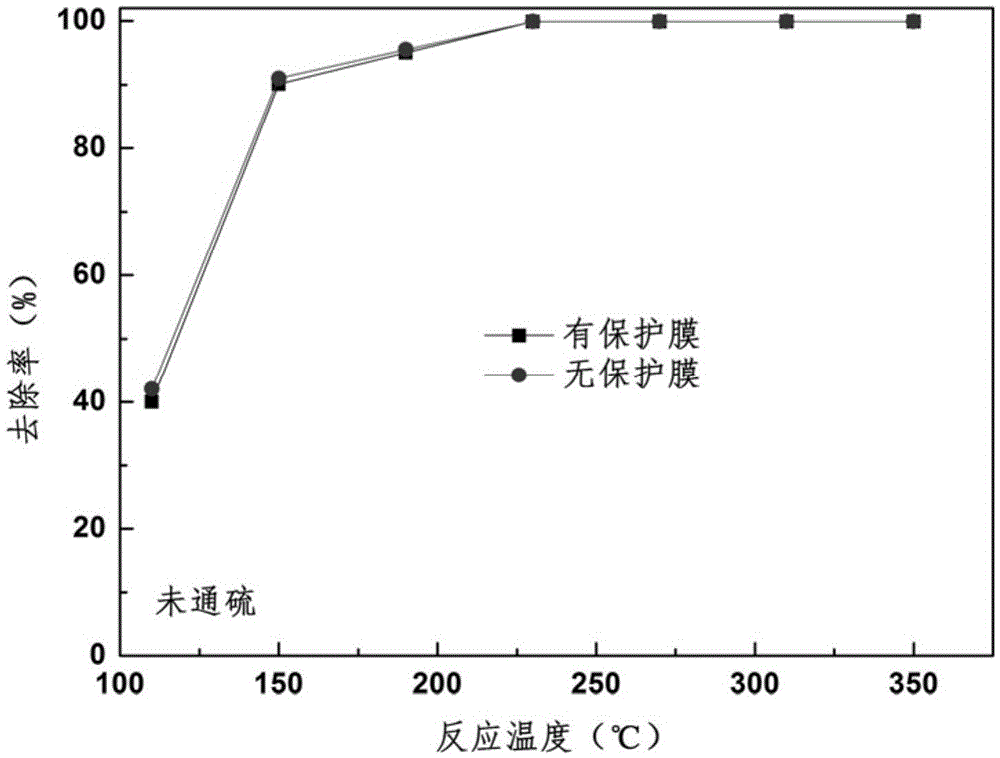

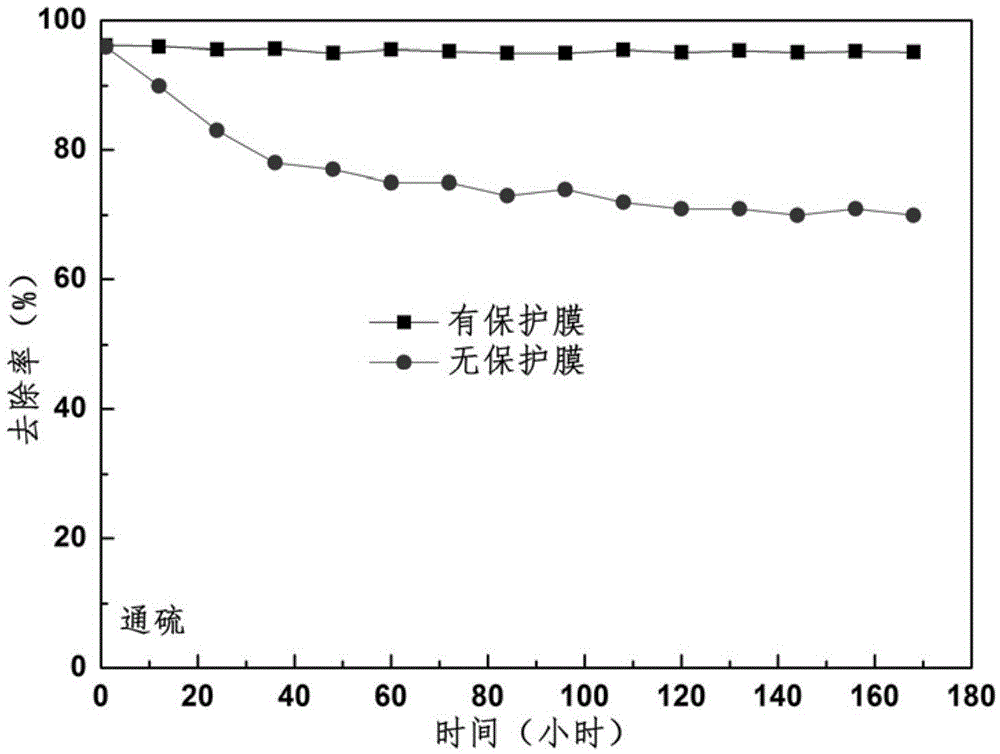

Image

Examples

Embodiment 1

[0036] Take 30 ml of water and 30 ml of absolute ethanol, mix well and add 0.96 ml of silane coupling agent, then add 4.8 g of titanium nanotubes and 12 g of titanium dioxide particles, then vigorously stir at 70°C for 5 hours, then wash with ethanol twice, The carrier precipitate was obtained after filtration. Take 0.1347 g of ammonium metavanadate, 1 g of cerium nitrate hexahydrate, and 0.0556 g of copper nitrate trihydrate, dissolve them in deionized water at 60°C, add the carrier to precipitate under vigorous stirring, and continue stirring for 4 hours to obtain the outer layer Protective film slurry.

[0037] Take 24.8157 grams of ammonium metavanadate, 121.7585 grams of cerium nitrate hexahydrate, and 0.0008 grams of silver nitrate, dissolve them in deionized water at 60°C, add 3378.264 grams of titanium dioxide particles under strong stirring, continue stirring for 4 hours, and then dry them at 60°C , Calcined at 350°C for 3 hours, and finally ground to obtain the main...

Embodiment 2

[0041] Take 30 ml of water and 30 ml of absolute ethanol, mix them evenly, add 4.46 ml of silane coupling agent, add 5.575 g of titanium nanotubes, 3.98 g of titanium dioxide particles, stir vigorously at 90°C for 12 hours, wash twice with ethanol, and filter to obtain Carrier precipitation. Take 0.3233 g of ammonium metavanadate, 1 g of cerium nitrate hexahydrate, and 0.5564 g of copper nitrate trihydrate, dissolve them in deionized water at 90°C, add the carrier to precipitate under vigorous stirring, and continue stirring for 8 hours to obtain the outer layer Protective film slurry.

[0042] Take 2.77 grams of ammonium metavanadate, 4.95 grams of cerium nitrate hexahydrate, and 0.0031 grams of silver nitrate, dissolve them in deionized water at 80°C, add 37.43 grams of titanium dioxide particles under strong stirring, continue stirring for 8 hours, and then dry them at 80°C , calcined at 450° C. for 5 hours, and finally ground to obtain the main body powder of the inner la...

Embodiment 3

[0045] Take 30 ml of water and 30 ml of absolute ethanol, mix well, add 2.57 ml of silane coupling agent, then add 5.14 g of titanium nanotubes and 5.14 g of titanium dioxide particles, then stir vigorously at 80°C for 24 hours, then wash with ethanol for 3 times, filter Afterwards, the carrier was precipitated. Take 0.2155 g of ammonium metavanadate, 1 g of cerium nitrate hexahydrate, and 0.2782 g of copper nitrate trihydrate, dissolve them in deionized water at 80°C, add the carrier to precipitate under vigorous stirring, and continue stirring for 18 hours to obtain the outer layer Protective film slurry.

[0046] Take 3.18 grams of ammonium metavanadate, 7.8 grams of cerium nitrate hexahydrate, and 0.0035 grams of chloroplatinic acid, dissolve them in deionized water at 90°C, add 92.78 grams of titanium dioxide particles under strong stirring, continue stirring for 12 hours, and then bake at 120°C dry, calcined at 600°C for 12 hours, and finally ground to obtain the main b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com